2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

In the rapidly evolving landscape of manufacturing and automotive repair, the importance of a reliable and efficient Cylinder Boring Machine cannot be overstated. As per a recent industry report from MarketsandMarkets, the global market for machine tools, which includes cylinder boring machines, is projected to reach USD 100 billion by 2025, driven by advancements in technology and increasing demand for precision-engineered components. This surge highlights the critical role that these machines play in ensuring performance and durability in engine rebuilding applications.

Selecting the right Cylinder Boring Machine is essential for businesses aiming to enhance productivity and maintain high-quality standards. A comprehensive analysis of current trends reveals that modern boring machines are equipped with features such as digital readouts, programmable controls, and advanced cutting technology, which significantly improve operational efficiency. Additionally, according to a survey conducted by the International Trade Administration, 84% of automotive repair shops indicated that investments in state-of-the-art machinery have led to a measurable increase in customer satisfaction and retention.

As the market continues to evolve, understanding the key factors to consider when purchasing a Cylinder Boring Machine is critical for both new and experienced professionals in the field. This guide will provide essential insights and recommendations to ensure that you make an informed decision tailored to your specific operational needs and objectives.

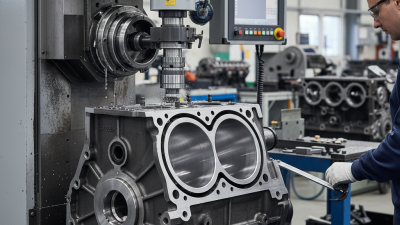

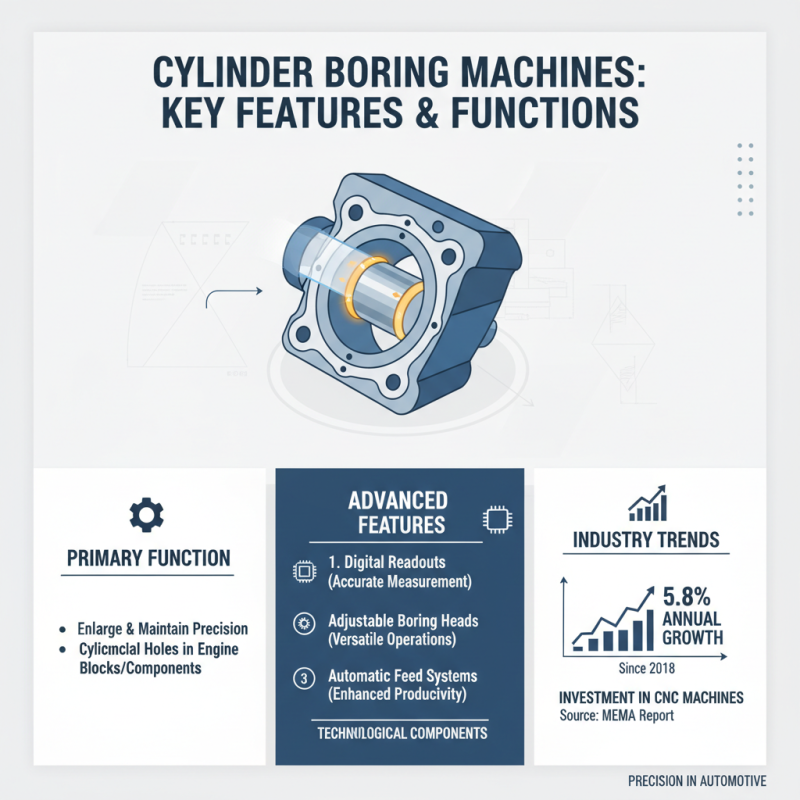

Understanding Cylinder Boring Machines: Key Features and Functions

When selecting a cylinder boring machine, understanding the key features and functions is essential to ensure optimal performance and efficiency in your operations. The primary function of these machines is to enlarge and maintain the precision of cylindrical holes within engine blocks and other components. A robust cylinder boring machine typically features advanced technological components, including digital readouts for accurate measurement, adjustable boring heads for versatile operations, and automatic feed systems that enhance productivity. According to a report from the Machinery Equipment Manufacturers Association (MEMA), investments in CNC (Computer Numerical Control) cylinder boring machines have seen a steady annual growth of approximately 5.8% since 2018, highlighting the increasing reliance on precision machinery in the automotive industry.

Additionally, the versatility of a cylinder boring machine is crucial for different operational needs, from standard boring to honing and resurfacing. Machines equipped with multi-function capabilities can save time and reduce costs, making them a valuable asset in a machine shop setting. The 2022 Global Machine Tool Market Report indicates that the demand for multi-function boring machines is on the rise, with projections suggesting that the segment will account for over 30% of the market share by 2025. This trend underscores the importance of investing in machines that not only meet current needs but can adapt to future demands within the automotive repair and manufacturing sectors. Understanding these core aspects of cylinder boring machines will equip you with the knowledge necessary to make informed purchasing decisions tailored to your unique requirements.

Assessing Your Needs: Identifying the Right Specifications for You

When selecting the right cylinder boring machine for your needs, it is essential to start by assessing your specific requirements. Begin by considering the types of engines you will be working on and the materials you will be boring. Different machines are designed for varying workloads; thus, choosing a machine that can handle the specifications of your tasks is pivotal. For instance, if you primarily work with aluminum or cast iron engines, ensure that the machine you select is adaptable to those materials. Additionally, evaluate the size and power of the machine, as these factors directly influence efficiency and usability in a shop environment.

Furthermore, consider the level of precision and control you require. Certain projects may demand tighter tolerances and higher accuracy, while others may allow for a more rugged approach. Look for specifications such as spindle speed, feed rate, and the machine's capability to accommodate different bore sizes. If you anticipate undertaking a variety of engine types, versatility in tooling options can also play a critical role. By thoroughly examining your specific needs and the machine's features, you can ensure that the cylinder boring machine you choose will enhance productivity and deliver quality results tailored to your operational requirements.

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

| Specification | Description | Considerations | Example Range |

|---|---|---|---|

| Boring Diameter | The range of bore sizes the machine can handle. | Determine the size of cylinders you commonly work with. | 20 mm to 200 mm |

| Spindle Speed | The speed at which the spindle operates, usually measured in RPM. | Higher speeds are useful for harder materials. | 1000 to 3000 RPM |

| Power | The motor power of the boring machine, usually measured in HP or kW. | Consider the material you will be boring. | 2 HP to 10 HP |

| Table Size | The dimensions of the work table for supporting workpieces. | Ensure it accommodates the largest part you will work on. | 600 mm x 800 mm |

| Control Type | Type of controls used; manual or CNC. | CNC provides more precision and automation. | Manual, Semi-Automatic, CNC |

| Weight | Total weight of the machine. | Heavier machines may provide better stability. | 150 kg to 2000 kg |

Evaluating Machine Types: Vertical vs. Horizontal Cylinder Boring Machines

When choosing between vertical and horizontal cylinder boring machines, the first aspect to consider is the type of engine or cylinder you will be working on. Vertical machines are often preferred for smaller, more intricate components, as their design allows for better precision in vertical alignment. This can be particularly beneficial when dealing with engine blocks that require tight tolerances.

Conversely, horizontal machines can handle larger components more efficiently due to their extended bed and sliding capabilities, making them ideal for heavy-duty applications.

Tips for selecting the right machine include evaluating the space you have available in your workshop. Vertical boring machines typically occupy less floor space, making them a good choice for smaller shops. On the other hand, if you frequently work with large parts or require more versatility, a horizontal boring machine could significantly enhance your productivity. Additionally, always consider the ease of use and availability of replacement parts, as this can impact your operational efficiency in the long run.

Ultimately, understanding the differences in functionality and application between vertical and horizontal cylinder boring machines will help you make an informed decision. Ensure that you assess your specific needs, workload, and future projects to choose the option that best aligns with your operational goals.

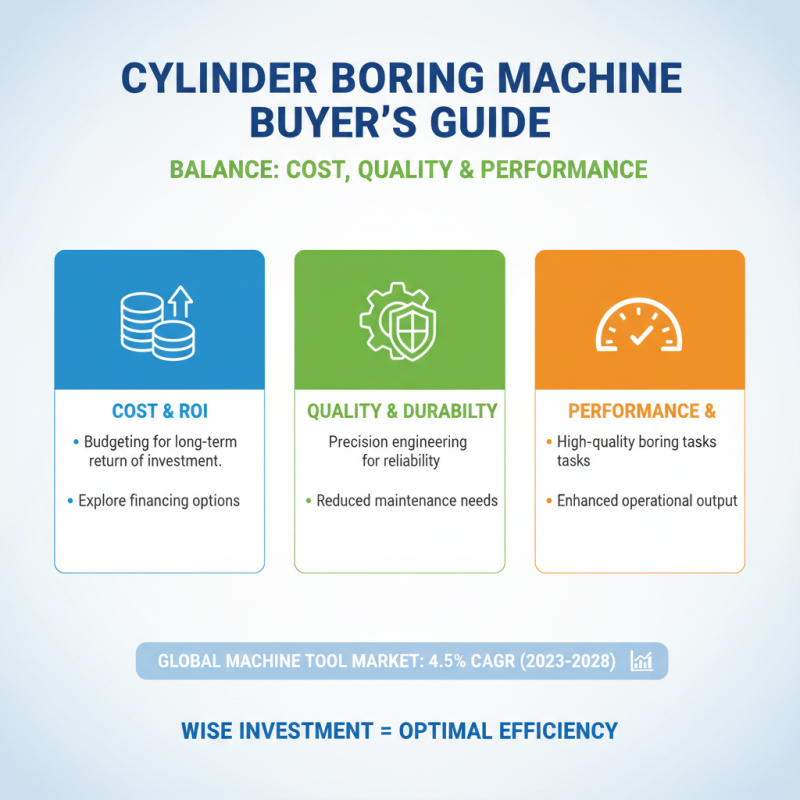

Budget Considerations: Balancing Cost with Quality and Performance

When looking to purchase a cylinder boring machine, understanding the balance between cost, quality, and performance is crucial. According to the Global Machine Tool Market Report, the industry is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2028. This accelerating demand emphasizes the need for manufacturers to invest wisely in machinery that not only meets budgetary constraints but also enhances operational efficiency. A well-crafted budget will allow businesses to explore options that provide the best return on investment over time while maintaining the capability to perform high-quality boring tasks.

Quality is often directly linked to performance, and investing in higher-quality machines can lead to better results in terms of accuracy and longevity. A study from the International Journal of Manufacturing Technology and Management highlighted that machines that are slightly more expensive often have lower maintenance costs and longer lifespans, ultimately saving money in the long run. It's essential to consider the total cost of ownership, which includes purchase price, maintenance, and operational costs, rather than just the initial investment. Balancing these aspects effectively can lead to significant improvements in both production efficiency and output quality, ensuring that the chosen cylinder boring machine aligns with the specific needs of your workshop.

Maintenance and Support: Ensuring Longevity of Your Cylinder Boring Machine

When investing in a cylinder boring machine, maintenance and support become pivotal for ensuring its longevity and efficient operation. According to a recent industry report from Machinery Maintenance Insights, up to 30% of machine failures can be attributed to inadequate maintenance practices. Regular upkeep not only minimizes downtime but also extends the life of the equipment, enabling users to achieve optimal performance throughout its operational lifespan. Operators should adhere to a rigorous maintenance schedule, including regular inspections, lubrication of moving parts, and timely replacement of worn components.

Moreover, accessing robust support services can significantly influence the overall efficiency of cylinder boring machines. Comprehensive training programs can enhance operator proficiency and reduce the likelihood of human errors, which, as reported by the Technical Association of Machine Tools, can account for nearly 25% of operational inefficiencies. Furthermore, establishing a proactive relationship with service providers ensures that technical support is available when needed, minimizing potential disruptions. As the machine's complexity increases, having a solid support network becomes an essential component of operational strategy, fostering both productivity and machine reliability.