2025 Top Vertical Lathe Trends: What to Expect in the Industry

In the ever-evolving world of manufacturing, vertical lathes have cemented their position as indispensable tools for precision machining. As we approach 2025, industry experts anticipate significant advancements that will shape the future of vertical lathe technology. According to Dr. Emily Hartman, a leading authority in machining innovations, "The evolution of vertical lathes is steering us towards unprecedented levels of efficiency and reliability in production processes."

This year, we’ll explore the key trends that are projected to redefine the landscape of the vertical lathe industry. From automation and smart technologies to sustainability practices, the innovations on the horizon promise to enhance not only productivity but also the environmental impact of manufacturing operations. As companies strive to keep pace with market demands, understanding these trends becomes crucial for stakeholders aiming to harness the full potential of vertical lathes.

As we delve into the emerging trends of vertical lathes, it is essential to consider how these developments will influence productivity, cost-effectiveness, and competitiveness in the manufacturing sector. The evolving capabilities of vertical lathes are set to drive unparalleled transformations, making it a pivotal topic for industry professionals to explore in the coming years.

Emerging Technologies in Vertical Lathe Manufacturing for 2025

As we move towards 2025, the landscape of vertical lathe manufacturing is poised for significant transformation driven by emerging technologies. Advanced automation is set to play a vital role in increasing productivity and precision in machining processes. The integration of robotic systems in vertical lathes will enhance operational efficiency by reducing manual intervention and ensuring consistent quality across the production line. Furthermore, the implementation of Internet of Things (IoT) technology will enable real-time data collection and analytics, facilitating predictive maintenance and minimizing downtime for manufacturers.

Tips: Embrace automation technologies by investing in training for your workforce. This will ensure smooth transitions as machines become more sophisticated and help your team adapt to new tools and processes seamlessly.

Another noteworthy trend is the increasing focus on sustainability in vertical lathe manufacturing. Companies are expected to prioritize eco-friendly practices by incorporating energy-efficient machines and materials that minimize waste. This approach not only meets regulatory standards but also appeals to environmentally conscious consumers and enhances a company's reputation in the market.

Tips: Consider evaluating your current processes for waste reduction opportunities. Small changes, such as optimizing cutting tools or reusing materials, can contribute to a more sustainable operation without compromising on performance.

Market Growth Predictions for Vertical Lathes in Various Industries

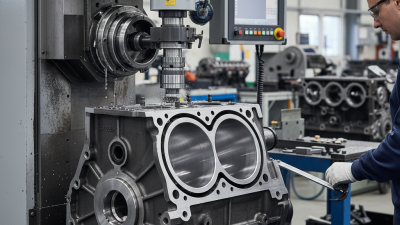

The vertical lathe market is poised for significant growth in the coming years, driven by advancements in technology and increasing demand across various industries. As manufacturers strive to enhance their operational efficiency, vertical lathes are becoming crucial for precision machining in sectors such as aerospace, automotive, and energy. The ability to handle larger components with precision has made vertical lathes an essential tool for heavy-duty applications, which is expected to boost their adoption.

Furthermore, as industries increasingly focus on automation and smart manufacturing, the integration of vertical lathes with advanced technologies such as IoT and machine learning is anticipated. This will not only enhance productivity but also improve the overall quality of machined parts. Market predictions indicate that the rising emphasis on sustainability and resource efficiency will also play a pivotal role in elevating the demand for vertical lathes, as companies seek to reduce waste and optimize their production processes.

These trends collectively illustrate a promising future for vertical lathes, highlighting their vital role in shaping the manufacturing landscape across multiple sectors.

Innovations in Materials and Components for Vertical Lathes

The vertical lathe industry is poised for significant transformation in the coming years, driven primarily by innovations in materials and components. According to a recent market analysis by ResearchAndMarkets, the global vertical lathe market is expected to grow at a CAGR of 5.2% through 2025, underscoring the increasing demand for advanced machining solutions. One of the critical trends is the shift towards lightweight and high-strength materials, such as composites and advanced alloys. These materials not only enhance the performance of vertical lathes but also contribute to reduced energy consumption and improved machining efficiency.

In addition to material advancements, the integration of smart technologies is also redefining vertical lathe components. The implementation of IoT and AI-driven systems allows for real-time monitoring and predictive maintenance, enhancing operational efficiency. According to a report from Allied Market Research, the adoption of smart manufacturing technologies could lead to a productivity increase of up to 30% in machining processes by 2026. This shift not only optimizes production timelines but also reduces waste and downtime, making vertical lathes an increasingly viable option for diverse manufacturing sectors. These innovations are critical in ensuring that vertical lathes meet the evolving demands of the modern manufacturing landscape.

2025 Top Vertical Lathe Trends: What to Expect in the Industry - Innovations in Materials and Components for Vertical Lathes

| Trend | Description | Expected Impact | Key Materials | Component Innovations |

|---|---|---|---|---|

| Smart Automation | Integration of IoT and AI for enhanced operational efficiency. | Increased productivity and reduced downtime. | Steel, Aluminum | Advanced sensors and machine learning algorithms. |

| Eco-friendly Manufacturing | Focus on sustainable practices and materials. | Reduction in carbon footprint and regulatory compliance. | Recyclable composites, Bio-based materials | Biodegradable lubricants and cutting fluids. |

| Advanced Tooling | Utilization of specialized cutting tools for enhanced performance. | Improved precision and tool longevity. | Carbide, Cermet | New coatings and geometries for better heat resistance. |

| Modular Design | Components designed for easy upgrades and maintenance. | Flexibility and cost-effectiveness in machine operations. | Aluminum alloys, High-strength plastics | Snap-on attachments and standardized interfaces. |

| Data-driven Insights | Leveraging big data for process optimization. | Enhanced decision-making and resource allocation. | Not applicable | Predictive maintenance tools and analytics software. |

Sustainability Trends Impacting Vertical Lathe Production

In recent years, the vertical lathe manufacturing industry has witnessed a shift towards sustainability as a key driver of production trends. As global awareness of environmental issues continues to rise, manufacturers are seeking ways to reduce their carbon footprint and improve resource efficiency. This includes the adoption of energy-efficient technologies and processes that minimize waste and lower energy consumption. Companies are increasingly investing in renewable energy sources, such as solar and wind, to power their operations, thereby aligning their production methods with sustainable practices.

Additionally, circular economy principles are becoming integral to vertical lathe production. Manufacturers are exploring ways to recycle materials and extend the lifecycle of products through remanufacturing. This not only reduces the reliance on virgin resources but also contributes to a more sustainable supply chain. By integrating eco-friendly materials and processes, companies can meet the growing demand from customers who prioritize sustainability in their purchasing decisions. As we move towards 2025, the emphasis on sustainable practices in vertical lathe production is expected to reshape the industry, driving innovation and efficiency while addressing environmental concerns.

2025 Top Vertical Lathe Trends: Sustainability Impact

Automation and Smart Technology Integration in Vertical Lathes

As we look toward 2025, the integration of automation and smart technology in vertical lathes is set to revolutionize the manufacturing landscape. The trend is largely driven by the industry's need for increased efficiency and precision. Automated systems allow for real-time monitoring of equipment, minimizing downtime and streamlining processes. By incorporating machine learning algorithms, these vertical lathes can predict maintenance needs and troubleshoot potential issues before they escalate, thereby ensuring continuous production.

Moreover, smart technology facilitates enhanced data collection and analysis. Advanced sensors embedded within vertical lathes gather information on various operational parameters, such as temperature and vibration. This data can be used to optimize machining conditions and improve product quality. Integration with cloud computing enables manufacturers to access and analyze this data remotely, allowing for better decision-making and resource allocation. As these technologies evolve, we can anticipate a significant shift towards fully automated machining environments, where human intervention is minimal, and precision is maximized.

Related Posts

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs