What is a Band Saw and How Does It Work?

A Band Saw is a powerful tool that many woodworkers and metalworkers rely on. Its unique design features a long, sharp blade that moves in a continuous loop. This allows for precise cuts and intricate shapes. Using a Band Saw can greatly enhance your craftsmanship, but it is essential to understand how it operates.

The mechanics of a Band Saw involve several key components. It has a motor that powers the blade, creating a smooth cutting motion. The blade tension and speed can be adjusted, allowing for different thicknesses and materials. However, improper use can lead to misalignments or safety hazards. Attention to detail is crucial when operating this equipment.

Learning to use a Band Saw effectively takes practice. Beginners might struggle with straight cuts or controlling the speed. It's important to reflect on your technique and make adjustments. Embracing these challenges can lead to improved skills and greater confidence. Ultimately, the Band Saw can be a valuable asset in your workshop.

What is a Band Saw?

A band saw is a powerful cutting tool commonly used in various woodworking and metalworking applications. It consists of a long, continuous blade that runs on wheels. The blade's teeth are designed to cut through materials with precision. This design allows for curved and intricate cuts that other saws cannot achieve. The band saw typically features adjustable blades and speeds, allowing users to work with different materials effectively.

When using a band saw, safety is a crucial consideration. Always wear safety goggles and keep your hands away from the blade. Beginners may find mastering this tool challenging. It requires practice to control the material and maintain straight cuts. Setting the correct tension on the blade can be tricky. If not done properly, the blade may wander off track during use. Users must consistently monitor the blade's condition, as dull blades can lead to inaccurate cuts.

Despite its advantages, the band saw does come with some limitations. It cannot cut materials that are too thick without strain. Additionally, if the blade breaks, it can pose dangers. Cleaning and maintaining the machine is essential, yet often neglected. Users may have to face the consequences of a poorly maintained tool. Therefore, understanding both its capabilities and its limitations is vital for effective use.

Band Saw Usage Statistics

This chart displays the usage percentages of band saws across different applications, highlighting their versatility in woodworking, metal cutting, plastic cutting, resawing, and making curved cuts.

The Anatomy of a Band Saw: Key Components Explained

A band saw is a versatile tool commonly used in woodworking and metalworking.

It consists of key components that work together to deliver precise cuts.

The saw blade is continuously looped around two wheels, which helps maintain tension.

This design allows for curved cuts and intricate designs, often unmatched by other saws.

The motor drives the wheels, moving the blade at high speeds. This ensures efficient cutting through various materials.

The table supports the workpiece and can often be adjusted for different angles.

Safety features, such as blade guards and emergency stop buttons, are essential.

According to industry reports, proper maintenance can extend blade life by as much as 50%.

Tips: Regularly check the blade tension and alignment.

A misaligned blade can cause binding and affect cut quality. Always use the correct blade for your material.

This helps achieve smoother cuts and reduces strain on the saw.

Dust collection systems can be integrated to maintain a clean workspace.

These systems improve visibility and safety while working. Yet, many users overlook this crucial aspect.

Neglecting cleanliness can lead to hazardous conditions.

Ensuring effective dust management can enhance both performance and safety.

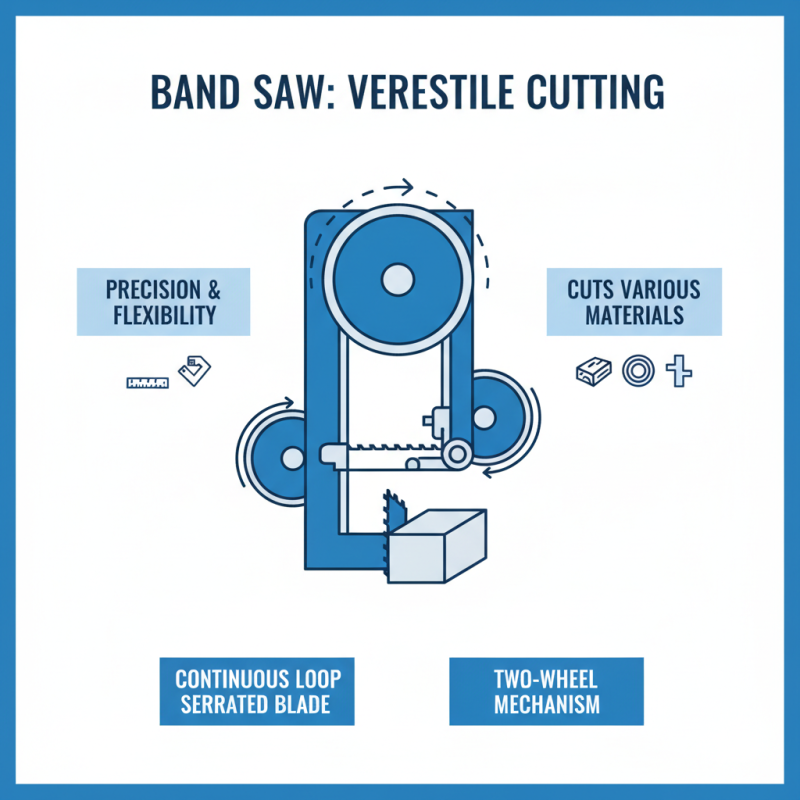

How Band Saws Cut: The Mechanism Behind the Blade

Band saws are versatile tools found in many workshops. They use a continuous loop of serrated blade. This design helps to cut through various materials. The blade moves on two wheels, creating a constant cutting action. This mechanism offers precision and flexibility.

The cutting process begins when the material is fed into the blade. The teeth of the blade dig into the material. As the blade advances, it creates a smooth and even cut. Different blade widths and tooth configurations allow for diverse applications. However, choosing the right blade can be challenging. Too thin a blade may break, while too thick can struggle with intricate cuts.

Users often overlook the need for proper tension on the blade. Inadequate tension can lead to crooked cuts. Additionally, improper alignment of the wheels can affect accuracy. Regular maintenance is crucial for optimal performance. Monitoring the blade’s condition ensures consistent results. It's a learning process that requires practice and adjustment.

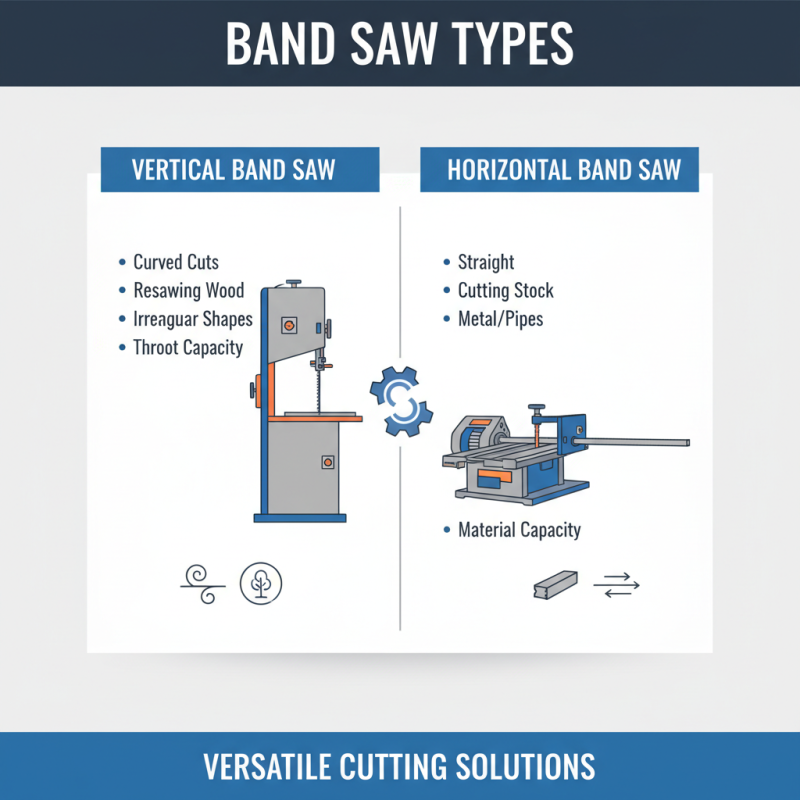

Types of Band Saws and Their Applications

Band saws are versatile tools used in various applications. Understanding the different types can enhance your woodworking or metalworking projects. There are two main types: vertical band saws and horizontal band saws. Each type serves specific purposes and has unique advantages.

Vertical band saws are great for intricate curves and detailed cuts. They allow for a vertical setup, which is ideal for resawing lumber. This method maximizes material usage. However, they may not be as stable for larger pieces. On the other hand, horizontal band saws excel at cutting through large materials. They offer straight cuts and are commonly used in metalworking. But, their limited maneuverability can be a downside when handling smaller workpieces.

Another option is portable band saws. These lightweight tools are handy for fieldwork. They can reach tight spaces but might lack power. Each type of band saw has its strengths and weaknesses. Understanding these allows users to choose the right tool for their project. Mistakes can happen if the wrong type is selected, leading to wasted material and effort.

Safety Tips When Using a Band Saw

Using a band saw can be an efficient way to cut various materials. However, safe practices are crucial to avoid accidents. Always wear suitable personal protective equipment, such as safety goggles and gloves. These simple steps protect you from flying debris and sharp edges.

Ensure your work area is clean and well-lit. Clutter can lead to mishaps while cutting. Keep your fingers at least six inches away from the blade for safety. This distance may seem excessive, but it’s crucial for preventing injuries. Maintain focus when operating the saw; distractions can lead to errors.

Before starting, check the saw's blade and tension. A dull or loose blade can cause unexpected movements. Regular maintenance is vital. Make adjustments slowly and carefully. Remember that the band saw is a powerful tool. Respect it and always prioritize your safety. Being mindful can significantly reduce the chances of accidents.

What is a Band Saw and How Does It Work? - Safety Tips When Using a Band Saw

| Feature | Description | Safety Tip |

|---|---|---|

| Blade Type | Wide, continuous loop used for cutting | Ensure the correct blade for the material |

| Cutting Capacity | Ability to manage various sizes of material | Always wear safety goggles |

| Power Source | Electric motor drives the blade | Keep hands clear of the blade while in motion |

| Applications | Cutting curves, rip cuts, and resawing | Secure workpiece properly before cutting |

| Maintenance | Regularly check blade tension and condition | Disconnect power before making adjustments |

Related Posts

-

How to Choose the Right Cylinder Boring Machine for Your Needs?

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs

-

10 Essential Tips for Choosing a Universal Milling Machine