Top Benefits of Using a Turret Milling Machine in Modern Manufacturing?

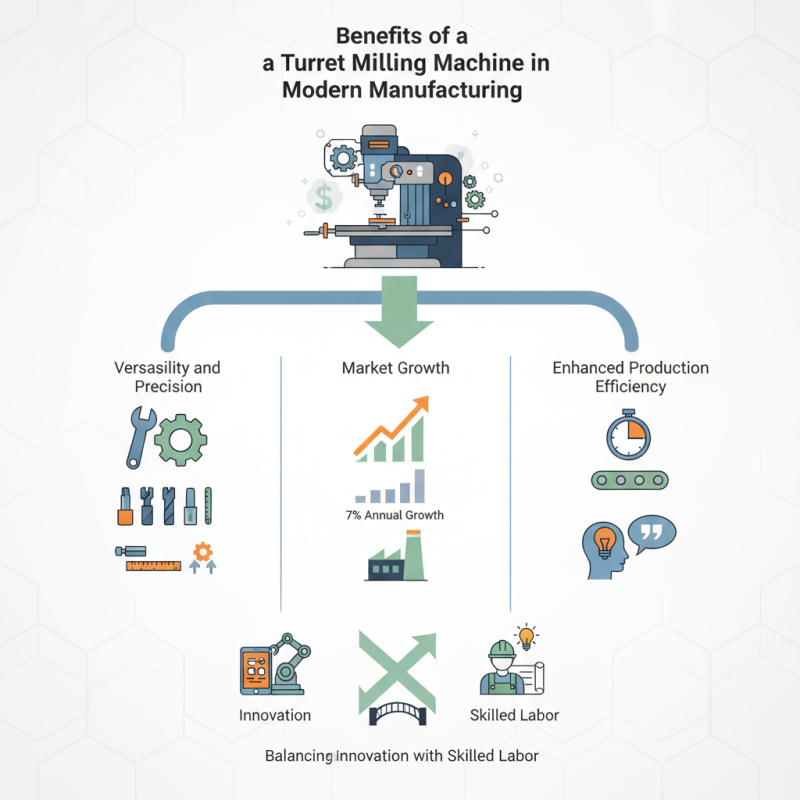

The Turret Milling Machine is pivotal in modern manufacturing. It offers versatility and precision for various applications. According to a report from the International Journal of Advanced Manufacturing Technology, the market for milling machines is set to grow by 7% annually. This growth highlights the importance of efficient tools like turret milling machines.

Expert James Foster, a leading authority in the milling machine industry, states, "Turret Milling Machines enhance production efficiency dramatically." His insights emphasize the machine's adaptability and effectiveness in diverse settings. The ability to easily modify setups allows manufacturers to meet specific needs.

However, reliance on technology does come with challenges. Not all operators master turret milling machine nuances. There are concerns about training quality and user proficiency. As the industry advances, addressing these gaps is crucial. Balancing innovation with skilled labor will define future successes.

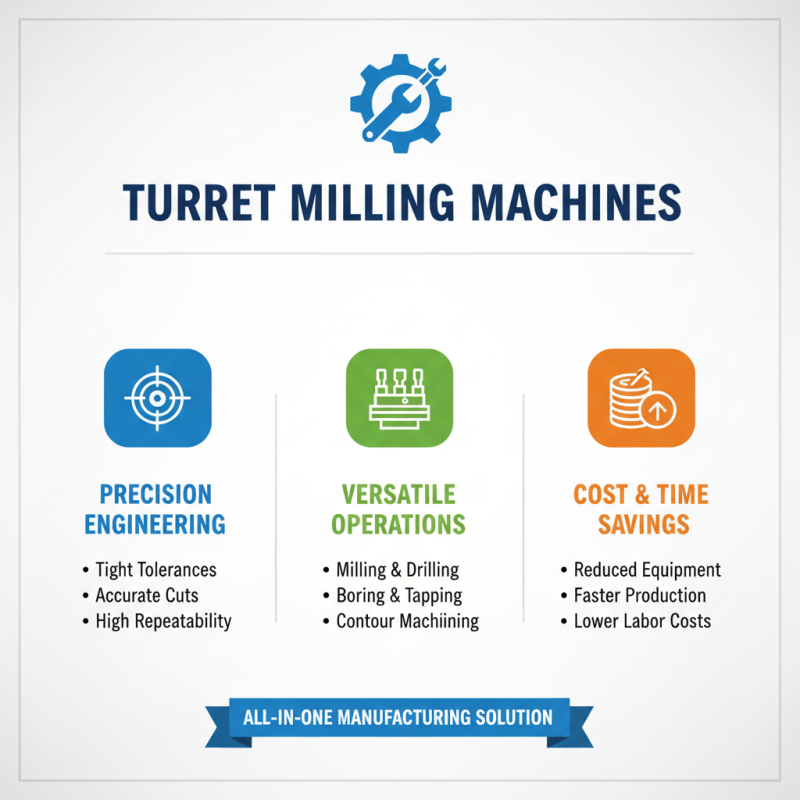

Advantages of Precision Engineering with Turret Milling Machines

Turret milling machines offer significant advantages in precision engineering. Their design allows for versatile operations, making them ideal for various manufacturing tasks. The ability to perform multiple functions with a single machine saves time and reduces the need for additional equipment. This efficiency can lead to cost savings for manufacturers.

Moreover, turret milling machines excel in producing detailed components. They enable precise cuts and complex shapes, essential for industries like aerospace and automotive. The vertical axis provides excellent visibility, allowing operators to monitor their work closely. However, achieving the highest levels of precision requires skilled operators who understand the machine's capabilities and limitations.

It is important to acknowledge potential challenges as well. Turret milling machines have a learning curve. New operators may struggle to master the controls. Regular maintenance is crucial to avoid performance inconsistencies. Without proper upkeep, the quality of the output may decline. Hence, investing in training and maintenance is vital for maximizing the benefits of turret milling in modern manufacturing.

Enhanced Versatility in Modern Manufacturing Processes

Turret milling machines have transformed modern manufacturing. Their design allows for intricate work on various materials. This capability ensures higher precision in component creation while enhancing productivity. According to a recent report, over 40% of manufacturers in the machinery sector utilize turret mills for their adaptability.

Manufacturers appreciate the versatility these machines offer. They can perform various tasks, such as drilling, boring, and milling. This flexibility reduces the need for multiple machines. By integrating turret mills, firms can streamline operations. It can lead to a 30% reduction in setup time, boosting overall efficiency.

Tips for Effective Use:

- Regularly maintain your turret milling machine. This practice ensures optimal performance.

- Experiment with different materials to fully explore the machine's capabilities.

- Train staff on all features, as this can enhance overall output.

While turret milling machines provide great advantages, some challenges exist. They require skilled operators for maximum efficiency. Additionally, initial investment costs can be high for smaller firms. However, the long-term benefits often outweigh these challenges. Adopting this technology might require adjustments, but the payoffs can be substantial.

Improved Efficiency and Time Savings in Production

Turret milling machines play a critical role in modern manufacturing, particularly in enhancing efficiency and saving time. According to industry reports, companies that adopt these machines experience a 30% reduction in cycle times. This is primarily due to their ability to execute complex cuts quickly. The ease of changing tools on turret mills allows for rapid setup, minimizing downtime in production.

Moreover, turret milling machines offer versatility that traditional machines often lack. They can handle a diverse array of materials with precision. Reports indicate that this adaptability can increase production capacity by up to 25%. However, some manufacturers may still hesitate to fully embrace this technology. Concerns about initial costs and the learning curve associated with new tools can hold back investments. Still, the long-term benefits outweigh these concerns significantly.

Data shows that employing turret mills can lead to a reduction in waste material by 15%. Efficient cutting paths reduce errors, leading to fewer rework processes. Yet, some operators may struggle to achieve the optimal settings, indicating a need for ongoing training and skill development. Thus, while the benefits are clear, the path to fully realizing these advantages may require commitment and reflection on operational practices.

Top Benefits of Using a Turret Milling Machine in Modern Manufacturing

| Benefit | Description | Impact on Production |

|---|---|---|

| Improved Precision | Turret milling machines provide enhanced accuracy in machining parts, reducing tolerance gaps. | Leads to better quality products and reduced scrap rates. |

| Increased Flexibility | These machines can handle a variety of tasks, making them suitable for different applications. | Enables adaptation to changing production needs without significant downtime. |

| Cost-Effective | Lower operational costs due to reduced waste and efficient use of materials. | Enhances the overall profit margins of manufacturing operations. |

| Enhanced Production Speed | Turret milling machines can perform multiple operations in one setup, reducing cycle time. | Results in faster turnaround times for orders. |

| User-Friendly Operation | Modern turret milling machines come equipped with intuitive controls and interfaces. | Reduces the learning curve for operators, minimizing training time. |

Cost-Effectiveness and Reduced Waste in Operations

In modern manufacturing, turret milling machines play a crucial role in improving cost-effectiveness and reducing waste. These machines excel at producing precise parts. This precision leads to fewer errors during production. When parts fit correctly, there's less material wasted. This efficiency translates into significant savings over time.

Operators can quickly set up turret milling machines for different tasks. This flexibility boosts productivity. Yet, some might struggle with machine adjustments. Proper training and experience are essential to avoid potential setbacks. Investing in skill development can yield long-term benefits.

Moreover, with the rise of automation, turret milling machines still hold their ground. They complement automated systems well. Smart usage can elevate overall manufacturing processes. However, businesses need to regularly assess their workflows. Continuous improvement is vital for maximizing operational efficiency.

User-Friendly Interfaces and Easy Maintenance Features

Turret milling machines are integral to modern manufacturing. Their user-friendly interfaces have transformed the way operators interact with these machines. Many systems feature touchscreen controls. This makes it easier to navigate complex functions. Operators can quickly adjust settings with minimal training.

Maintenance is another significant advantage. Many turret milling machines feature self-diagnostic tools. These tools alert users to potential issues before they escalate. Regular upkeep tasks are simplified, often requiring just basic tools. However, it's essential to remember that neglecting routine maintenance can lead to unexpected breakdowns.

Despite their advantages, some users may still struggle. Not all interfaces are intuitive, and learning curves can vary. Operators may find certain features underwhelming, lacking detailed instructions. Reflecting on these experiences can lead to better machine choices in the future. Continuous feedback helps manufacturers improve their designs further. Ideally, user experiences can shape the next generation of turret milling machines.

Top Benefits of Using a Turret Milling Machine in Modern Manufacturing

Related Posts

-

2025 Top Universal Milling Machine Features and Buying Guide

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

2026 How to Use Milling Machine X6325 Effectively?

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

How to Choose the Right Universal Milling Machine for Your Needs

-

2026 Best Sheet Metal Shearing Machine Reviews and Buying Guide?