Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

In the rapidly evolving landscape of manufacturing, the importance of precision and versatility cannot be overstated. The "Turret Milling Machine X6325" stands out as a crucial tool in many workshops, renowned for its ability to enhance machining operations across various projects. According to a recent report by the International Manufacturing Technology Show, turret milling machines are deemed essential by 78% of machinists for their adaptability in handling different materials and designs, underscoring their relevance in today’s industrial setting.

Expert machinist Dr. Andrew Patel, a leading authority in milling technology, emphasizes the value of the Turret Milling Machine X6325, stating, "This machine not only improves efficiency but also ensures a level of precision that is indispensable in modern manufacturing." With its robust features, including adjustable spindle speeds and a wide range of accessories, the X6325 offers unparalleled capabilities, making it a preferred choice for both professionals and hobbyists alike. As we delve into the top 10 benefits of utilizing the Turret Milling Machine X6325, it becomes evident that this remarkable tool is more than just a machine; it is an essential partner in achieving machining excellence.

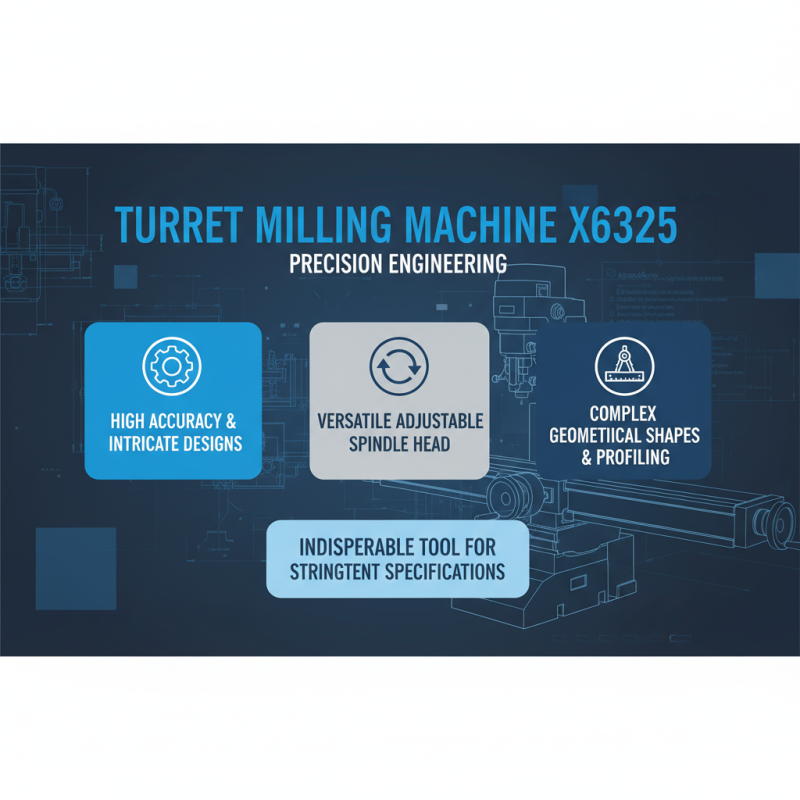

Benefits of Precision Engineering with Turret Milling Machine X6325

The Turret Milling Machine X6325 embodies precision engineering, making it an indispensable tool for various machining projects. One of its most significant advantages is the ability to achieve intricate designs with high accuracy. Its versatile spindle head can be easily adjusted, allowing for a range of angles and cuts. This adaptability is essential for tasks that require detailed profiling and complex geometrical shapes, ensuring that each component meets stringent specifications without the need for multiple machines.

Another notable benefit of the X6325 is its efficiency in the machining process. With features that support quick setup times and straightforward operation, users can minimize downtime and boost productivity. The machine's robust construction ensures stability during operation, which further enhances the quality of the finished products. Moreover, the consistent precision achieved by the turret milling process allows for reduced waste and rework, promoting a more sustainable approach to manufacturing. By combining these elements, the turret milling machine not only elevates the standard of engineering projects but also fosters innovation in design and fabrication.

Enhanced Machining Efficiency and Productivity of X6325 Models

The X6325 turret milling machine stands out for its exceptional machining efficiency, significantly enhancing the productivity of various projects. One of the primary advantages of this model is its versatile capabilities, allowing users to perform a wide range of operations including drilling, boring, and milling. This flexibility is particularly beneficial for workshops that handle diverse tasks, enabling them to switch between different machining processes seamlessly without compromising quality or speed.

Moreover, the ergonomic design and advanced features of the X6325 contribute to a more streamlined workflow. The machine's easy-to-use controls and precise adjustments facilitate a faster setup time, allowing operators to focus more on production rather than spending excessive time on machine configuration. Additionally, the robust construction of the X6325 ensures stability during operation, which leads to consistent results and reduces the likelihood of errors. These advancements collectively not only boost the overall output but also lead to a more efficient utilization of resources, making the X6325 an invaluable asset in any machining environment.

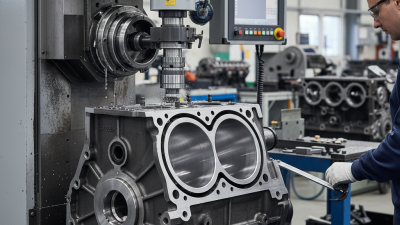

Versatility in Material Handling: A Comprehensive Overview of X6325

The turret milling machine X6325 is recognized for its exceptional versatility in handling a variety of materials, making it a valuable asset in any workshop. Its design allows for precise adjustments, enabling operators to mill metals, plastics, and even wood with ease. This adaptability is particularly beneficial when projects require changing materials mid-production, saving time and enhancing workflow efficiency. The machine’s ability to accommodate an array of workpieces means that users can tackle diverse tasks, from detailed intricate designs to heavy-duty machining operations.

Furthermore, the X6325's robust construction and advanced features facilitate consistent performance across different material types. With variable speed settings and adjustable cutting depths, operators can optimize their processes for different density materials, ensuring high-quality results regardless of the project requirements. This not only leads to improved productivity but also minimizes waste by allowing for precise cuts. Overall, the comprehensive overview of the turret milling machine X6325 highlights its essential role in modern machining practices, especially for those looking to maximize their capabilities across various materials.

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

Cost-Effectiveness and Long-Term Investment of Using X6325 Machines

When considering the cost-effectiveness and long-term investment of a turret milling machine like the X6325, it’s essential to recognize how these machines enhance project efficiency and reduce operational costs over time. The initial investment may seem significant, but the precision and versatility they offer can lead to substantial savings in material waste and labor hours. By producing highly accurate components, users can minimize the need for costly rework, making the mill itself a valuable addition to any workshop.

Moreover, turret milling machines are known for their durability. Investing in a robust model ensures that your machine will remain functional for years to come, even under heavy use. This longevity translates to lower replacement costs in the long run, positioning the X6325 as a wise choice for both hobbyists and professionals alike. Regular maintenance and care can further enhance the lifespan of these machines, ensuring that your investment continues to pay dividends.

**Tips:** To maximize the cost-effectiveness of your turret milling machine, always keep it well-maintained. Regular cleaning and prompt repairs can prevent costly downtime. Additionally, familiarizing yourself with its features through training can enhance efficiency, enabling you to get the most from your investment. Consider batch production for similar components to optimize time and materials.

Improved Safety Features and Operator Comfort in Turret Milling Processes

The turret milling machine X6325 has emerged as a pivotal tool in the machining industry, particularly due to its assurance of improved safety features and enhanced operator comfort during milling processes. Recent industry reports indicate that machine-related accidents account for approximately 24% of all workplace injuries in manufacturing environments (OSHA, 2022). By integrating advanced safety mechanisms such as automatic shut-off systems and enhanced guarding, the X6325 minimizes the risk of accidents, promoting a safer working environment for operators. These features ensure that the risk of injury due to machine malfunctions or operator error is significantly reduced, which is critical in maintaining productivity and morale in the workspace.

Moreover, operator comfort has become a primary consideration in machine design, as evidenced by studies from the National Institute for Occupational Safety and Health (NIOSH). Their findings reveal that ergonomic workstations can improve productivity by up to 20% while reducing fatigue-related errors. The X6325 turret milling machine incorporates designing elements that support ergonomic practices, such as adjustable height worktables and user-friendly control layouts. This focus on operator comfort not only enhances productivity but also contributes to long-term employee satisfaction and retention, a crucial aspect in an industry facing skilled labor shortages. By prioritizing safety and ergonomics, the turret milling machine X6325 stands out as a beneficial solution for modern milling projects, ultimately driving better outcomes for businesses and their workforce.

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

| Benefit | Description | Impact on Projects |

|---|---|---|

| Improved Safety Features | Incorporates advanced safety systems to minimize accidents. | Enhances operator confidence and reduces work-related injuries. |

| Ergonomic Design | Features comfortable controls and adjustable components. | Reduces operator fatigue and increases productivity. |

| Versatility | Can perform multiple milling operations with ease. | Saves time and space compared to multiple machines. |

| Enhanced Accuracy | Employs precise measurement tools for exact machining. | Ensures high-quality output and reduces material waste. |

| Ease of Use | User-friendly interface and straightforward controls. | Minimizes training time for new operators. |

| Cost Efficiency | Reduces operational costs through efficient processes. | Increases profit margins on projects. |

| Reduced Noise Levels | Operates at lower noise frequencies. | Creates a more pleasant working environment. |

| Maintenance Accessibility | Design allows easy access for maintenance checks. | Enhances machine longevity and reliability. |

| Consistent Production | Stable performance with minimal downtime. | Improves overall production schedules and deadlines. |

| Adaptable Technology | Compatible with various modern attachments and upgrades. | Stays relevant with changing production needs. |

Related Posts

-

2025 Top Universal Milling Machine Features and Buying Guide

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

How to Choose the Right Universal Milling Machine for Your Needs

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry