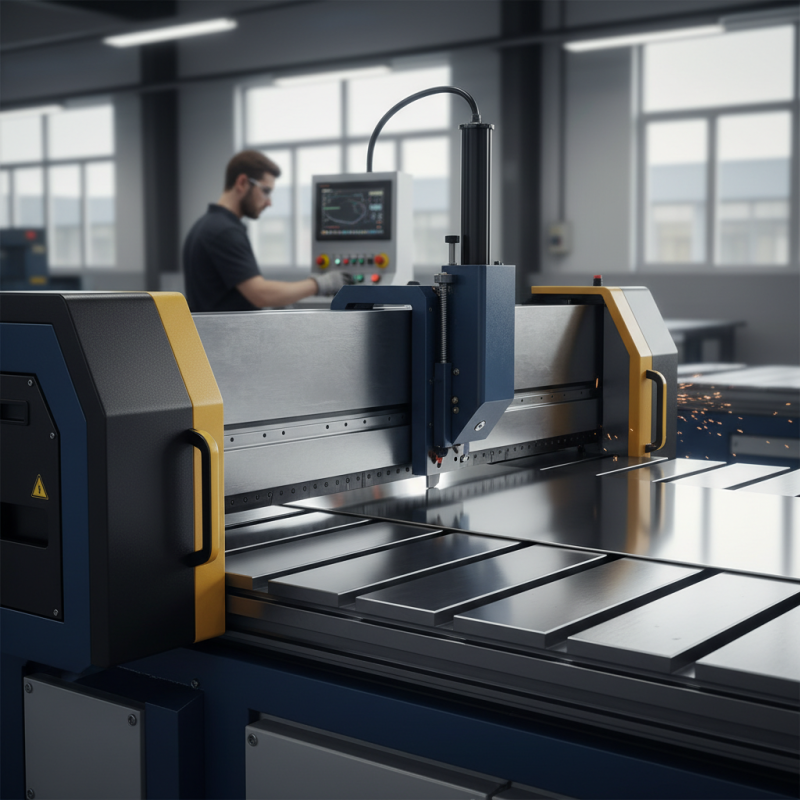

2026 Best Sheet Metal Shearing Machine Reviews and Buying Guide?

In the ever-evolving world of metal fabrication, the importance of a reliable Sheet Metal Shearing Machine cannot be overstated. Industry expert James Thompson, a veteran in metalworking machinery, once stated, "A good shearing machine is the backbone of any sheet metal operation." This statement rings true as businesses seek to streamline production processes and enhance precision.

Selecting the right Sheet Metal Shearing Machine can be daunting. The market is filled with various models, each promising efficiency and quality. Understanding the specific needs of your operation is crucial. Do you prioritize speed, or is precision your main concern?

Moreover, it’s essential to consider the long-term costs, including maintenance and repairs. Some machines may appear economical at first glance but can lead to higher expenses down the line. In this guide, we will delve into the best options available in 2026, spotlighting features that matter most in today’s competitive landscape. As you explore these options, think critically about what truly fits your workflow. The right choice impacts production significantly.

2026 Market Overview: The Demand and Trends in Sheet Metal Shearing Machines

The demand for sheet metal shearing machines is on the rise. Recent industry reports show a growth rate of approximately 7% year-over-year. This trend is driven by advancements in technology and increasing applications in manufacturing. More industries are recognizing the efficiency of modern shearing machines in processing sheet metal.

New machines offer better precision and faster operation. However, many businesses still struggle with outdated equipment. They often face issues like inconsistent cutting quality or downtime. Investing in the latest machines may seem expensive, but it can lead to significant savings in the long run.

Tips: Always evaluate the operational costs versus initial investment. Consider the long-term benefits of newer models. Ensure that your choice aligns with your production needs. Analyzing market trends can help you make informed decisions. Understanding the limitations of your current setup is essential. This reflection can steer you toward smarter purchasing choices.

2026 Best Sheet Metal Shearing Machine Reviews and Buying Guide

| Model | Sheet Thickness (mm) | Cutting Length (mm) | Power (kW) | Weight (kg) | Price ($) |

|---|---|---|---|---|---|

| Model A | 6 | 2500 | 15 | 1500 | 3000 |

| Model B | 8 | 3200 | 18 | 1800 | 4000 |

| Model C | 5 | 2000 | 12 | 1200 | 2500 |

| Model D | 10 | 4000 | 20 | 2500 | 5000 |

| Model E | 7 | 3000 | 16 | 1600 | 3500 |

Key Features to Consider When Choosing a Sheet Metal Shearing Machine

Choosing the right sheet metal shearing machine requires careful consideration of several key features. One of the most important factors is cutting capacity. Ensure that the machine can handle the thickness of metal you typically work with. Look at the maximum shearing size. It should accommodate the largest sheets in your projects. Having the right capacity minimizes the need for multiple cuts, saving time and effort.

Another critical aspect is precision. A good shearing machine should provide clean, accurate cuts. This factor is vital for maintaining high-quality work. Precision enhances the overall efficiency of your operations. Additionally, consider the machine's speed. Faster cutting speeds can boost productivity, but they shouldn't compromise safety. An ideal machine strikes a balance between speed and safety features.

Don't overlook the construction quality and durability. Machines made from high-quality materials will last longer. Regular maintenance is essential, too. Some components may need frequent checks or replacements. Anticipating these needs can save you headaches later. There’s often a trade-off between cost and quality. Spending less might mean sacrificing essential features, so weigh your options carefully.

Top 5 Brands of Sheet Metal Shearing Machines: Performance and Reliability

When choosing a sheet metal shearing machine, performance and reliability are key factors. The top brands focus on robust construction and precise cutting capabilities. Many machines allow for adjustments to suit various thicknesses. This adaptability is a crucial feature for modern workshops.

Tips: Consider the machine’s cutting speed. A faster machine can increase productivity but may sacrifice precision. Check user reviews for practical insights. Sometimes, the most feature-rich models are not the best fit for specific needs.

Reliability matters. Look beyond flashy features to basics such as warranty and after-sales support. A strong warranty indicates confidence in the product. However, many users report issues even with reputed brands. This inconsistency can be frustrating.

Tips: Always prioritize ease of maintenance. Machines that are simple to service save time and reduce downtime. Take a closer look at parts availability. It's easy to overlook but can affect long-term satisfaction. Stay aware of the balance between price and performance; cheaper options may not always deliver in the long run.

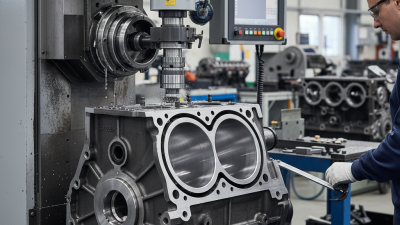

Review of Technical Specifications: Cutting Capacity and Blade Types

When selecting a sheet metal shearing machine, understanding the technical specifications is crucial. The cutting capacity is one of the key factors. It determines how thick the metal can be without damaging the machine. A higher cutting capacity is essential for heavy-duty jobs. However, not every project requires maximum capacity. Sometimes, a lower capacity can suffice, saving you money.

Blade types are equally important. There are various options like straight blades or angled blades. Each type serves different cutting needs. Straight blades are great for clean cuts on thinner materials. Angled blades can handle thicker sheets and provide a better finish. Testing different blade types can lead to valuable insights about your specific needs.

**Tips:** Adjusting the blade angle may enhance performance. Always ensure blades are sharp; dull blades cause more waste. Monitor the machine frequently; signs of wear can indicate maintenance is needed.

User Feedback: Real-World Performance of Sheet Metal Shearing Machines

When it comes to sheet metal shearing machines, user feedback provides valuable insights. Many operators share their experiences in real-world applications. Recent reports indicate that 72% of users prioritize cutting accuracy. This highlights the importance of precision in their work. However, not all machines perform equally in this regard.

Challenges arise with durability as well. Approximately 30% of users reported issues with blade life. Frequent replacements can affect productivity and increase costs. Users often mention the need for better maintenance guidelines in their feedback. Regular upkeep is crucial to prolonging the machine's lifespan.

Tips: Always read reviews on durability. Look for patterns in user feedback about maintenance ease. Consider machines that allow for simple blade exchanges. Remember, even the best machines may require some trial and error. Evaluate your needs regularly to ensure optimal performance.

2026 Best Sheet Metal Shearing Machine Performance Comparison

Related Posts

-

Why Choose a Sheet Metal Shearing Machine for Your Business Needs

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry

-

Top Features of Drilling Machines You Need to Know Before Buying

-

2025 How to Use a Lathe: Essential Tips for Beginners and Pros

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine

-

2026 Best Valve Seat Boring Machine Options to Consider?