2026 Best Valve Seat Boring Machine Options to Consider?

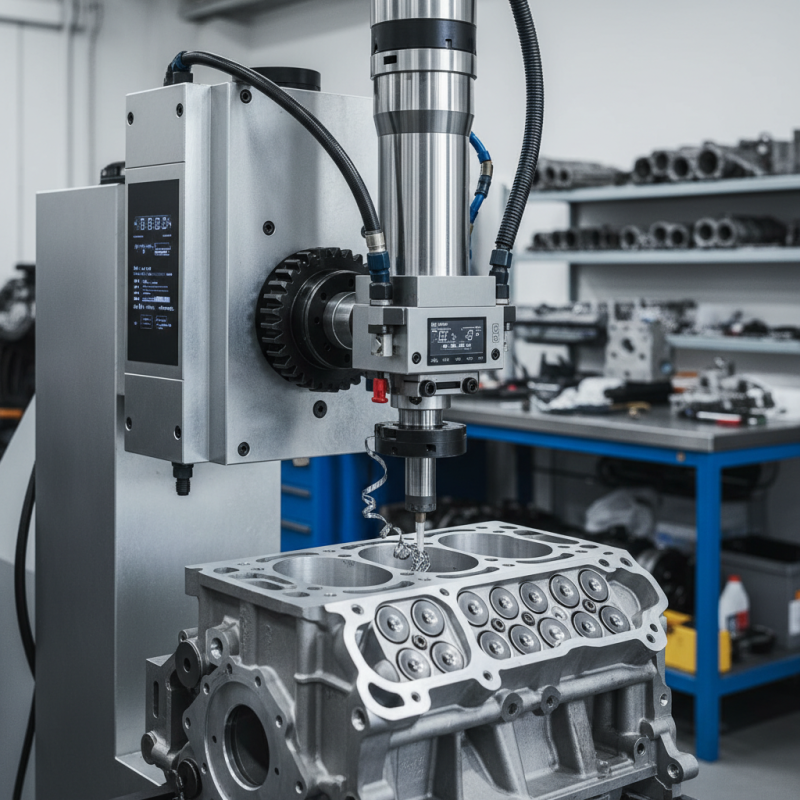

In the world of automotive repair, a Valve Seat Boring Machine is essential for maintaining engine performance. As vehicles become more complex, using the right machine can make a significant difference. A quality boring machine ensures precise seat alignment, which enhances combustion efficiency and prolongs engine life.

Choosing the right Valve Seat Boring Machine is not always straightforward. With so many options on the market, one may feel overwhelmed. Factors like size, speed, and accuracy come into play. Some machines lack the precision needed for modern engines, making it crucial to conduct thorough research.

Budget constraints also pose a challenge. It’s tempting to go for cheaper models, but they may compromise quality. Investing in a reliable Valve Seat Boring Machine can yield long-term benefits. Assess your needs and explore the features that matter most before making your decision. Investing time in understanding these machines will pay off in effective repairs.

Overview of Valve Seat Boring Machines and Their Importance

Valve seat boring machines play a critical role in automotive engine repair. They ensure precise machining of valve seats, which is essential for optimal engine performance. According to recent industry reports, accurate valve seat fitment can enhance combustion efficiency by up to 15%. This improvement directly impacts fuel economy and reduces harmful emissions.

Choosing the right boring machine can be daunting. Factors to consider include precision, ease of use, and versatility. Machines vary significantly in their capabilities. Some may only work with specific engine types. Inadequate research could lead to costly mistakes. Don't rush this decision. Consider the specific needs of your shop.

Tip: Regular maintenance is crucial for these machines. Keeping them in top shape ensures consistent performance. Small issues can lead to larger problems if overlooked. Pay attention to what your machine tells you. Maintenance logs can help track its performance over time. Delegate this task if necessary.

Key Features to Look for in a Valve Seat Boring Machine

When selecting a valve seat boring machine, it's crucial to consider key features that enhance functionality. Precision is paramount; the machine should provide accurate alignment and adjustable cutting depths. Look for machines with sturdy construction. A solid build ensures longevity and minimizes vibrations during operation. This can affect the quality of the bore and ultimately the engine performance.

Another important aspect is user-friendliness. A well-designed interface can make a significant difference. Controls should be intuitive, allowing operators to adjust settings easily. This is especially vital in busy shop environments. Furthermore, the availability of accessories can improve the machine's versatility. Consider options like different cutting tools or cooling systems to enhance efficiency.

Maintenance requirements should also be evaluated. Some machines are easier to service than others. Regular upkeep is necessary to keep them functioning at peak performance. Accessibility to wear-and-tear parts is a practical consideration. Reflecting on user feedback can provide insights into potential issues or strengths. Investing time in research is essential for making an informed choice about the right valve seat boring machine.

2026 Best Valve Seat Boring Machine Options to Consider

| Machine Model | Drilling Range (mm) | Power (HP) | Weight (kg) | Key Features |

|---|---|---|---|---|

| Model A | 30 - 100 | 8 | 150 | Digital depth control, adjustable speed |

| Model B | 25 - 90 | 7 | 120 | Auto feed, robust design |

| Model C | 20 - 80 | 6 | 100 | Compact, easy to transport |

| Model D | 35 - 110 | 9 | 180 | High precision, multiple angle settings |

| Model E | 40 - 120 | 10 | 200 | User-friendly interface, automatic lubrication |

Top Brands and Models of Valve Seat Boring Machines in 2026

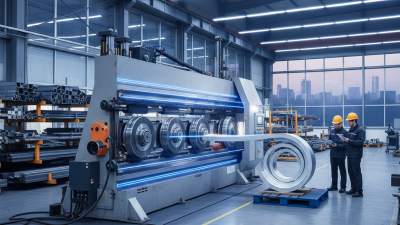

When considering valve seat boring machines in 2026, it’s essential to focus on top brands and models. Look for machines that offer precise adjustments. Operators often appreciate machines with easy-to-use interfaces. These features reduce the learning curve for new users.

One crucial aspect is the machine's durability. Many brands invest in high-quality materials. This investment usually leads to a longer lifespan. However, some machines may rush to market. Not all components stand up to heavy use. It’s wise to read reviews carefully before making a selection.

Tip: Always check for service options and warranties. A reliable after-sales service can save you time and money. Ask other users about their experiences. Their feedback is invaluable. Keep in mind that no machine is perfect. Be prepared to evaluate your specific needs closely. This will guide you to the best option available.

Comparative Analysis of Price and Performance for Popular Machines

When considering valve seat boring machines for 2026, it’s crucial to analyze both price and performance. Industry reports indicate that the average cost of a reliable valve seat boring machine ranges from $15,000 to $30,000. The performance metrics vary widely within this price range. Machines on the lower end typically offer basic features and slower operation speeds, while premium models provide advanced technology for precision and speed.

A recent study highlighted that machines capable of boring at speeds exceeding 45 RPM have a clear performance advantage. They ensure higher accuracy and faster turnaround times in workshops. The data also suggests that user-friendly interfaces are increasingly important. A machine with good operator feedback can improve productivity by 20%. However, some high-priced options might not deliver proportional benefits.

Reflecting on the performance-to-price ratio, a machine that seems cost-effective may require frequent maintenance. This can escalate total ownership costs. A thorough assessment of part longevity and service availability is essential. Selecting a bench of machines solely based on initial costs might lead to regrettable choices in the long run.

Maintenance Tips for Maximizing the Lifespan of Valve Seat Boring Machines

Maintaining valve seat boring machines is crucial for optimal performance. Regular maintenance can significantly extend their longevity. According to industry reports, proper care can enhance machine lifespan by up to 30%. This means more productivity and reduced costs in the long run.

One essential aspect is regular lubrication. A well-lubricated machine operates smoothly, reducing wear and tear. Neglect can lead to overheating. It's also vital to check the alignment frequently. Misalignment can cause uneven wear on parts, creating issues that require costly repairs.

Another necessary task is to clean cooling systems. Clogged systems lead to increased temperatures. This can decrease machine efficiency and cause failures. Regular inspections are essential but often overlooked. Small issues can escalate if not addressed promptly. Investing time in these maintenance practices is beneficial. Neglecting them will lead to regrets later.

2026 Best Valve Seat Boring Machine Performance Comparison

Related Posts

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

2025 How to Use a Lathe: Essential Tips for Beginners and Pros

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs