How to Choose the Best CNC Lathe Machine for Your Workshop?

Choosing the right CNC Lathe Machine for your workshop is essential. This machine can significantly impact your productivity and project quality. An ideal CNC lathe allows for precision and efficient design.

Before making a selection, consider your specific needs. Not all CNC lathe machines are the same. Some may lack features like speed control or automatic tool changes. Each feature impacts your workflow.

You might find yourself lost in specifications. It's important to reflect on what truly matters for your projects. Ask questions before diving into purchases. This process could save time and cost. Trust your instincts, but also research thoroughly.

Selecting the Right CNC Lathe: Key Factors to Consider

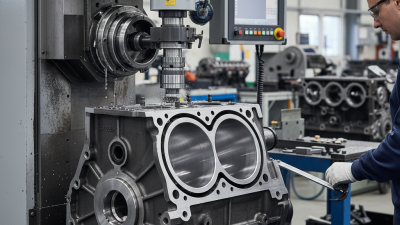

When selecting the right CNC lathe for your workshop, several key factors emerge. The machine's precision and rigidity are paramount. According to recent industry reports, a lathe with a higher rigidity can maintain tolerances within ±0.002 inches. This level of accuracy is critical for high-quality machining processes. Finding a balance between stability and speed is essential. Lathe speed can significantly affect production efficiency. Machines with variable speed control often offer better adaptability.

Another important aspect is the size and swing capacity of the lathe. Workshops must consider their own space and the dimensions of the workpieces. A lathe with too small a swing might limit the types of projects handled. In contrast, models with larger capacities can lead to wastage of space and resources if not used effectively.

Additionally, the control system plays a critical role in usability. Many operators feel overwhelmed by complex interfaces. A user-friendly system can improve the learning curve and productivity. Yet, it's essential to remain cautious. Advanced features can drive costs up without guaranteeing return on investment. Reflection on actual workshop needs is necessary. Balancing features, budget, and operational capacity is vital in ensuring the right choice.

Key Factors in Choosing the Best CNC Lathe Machine

This chart illustrates the importance of various factors when selecting a CNC lathe machine for your workshop. The data is based on user preferences and considerations in the CNC machining community.

Understanding Different Types of CNC Lathes and Their Applications

When selecting a CNC lathe for your workshop, understanding the different types is crucial. There are several types of CNC lathes, including vertical and horizontal models, each serving specific applications.

Vertical lathes are ideal for large, heavy workpieces, while horizontal lathes excel in smaller, precision tasks. The choice often depends on workshop size and intended projects.

Tips: Look for a machine that fits your workshop space. Consider the materials you'll be working with too. Some lathes handle certain metals or plastics better than others.

CNC lathes also vary in complexity. Entry-level machines are simpler to use but may limit your projects.

Advanced lathes offer more features, which can overwhelm beginners. Think about your skill level and project goals. A balance between complexity and usability is key.

Tips: Test different machines if possible. This hands-on experience can clarify your needs. Remember, choosing the right lathe is not only about technology but also about how it suits your creative vision.

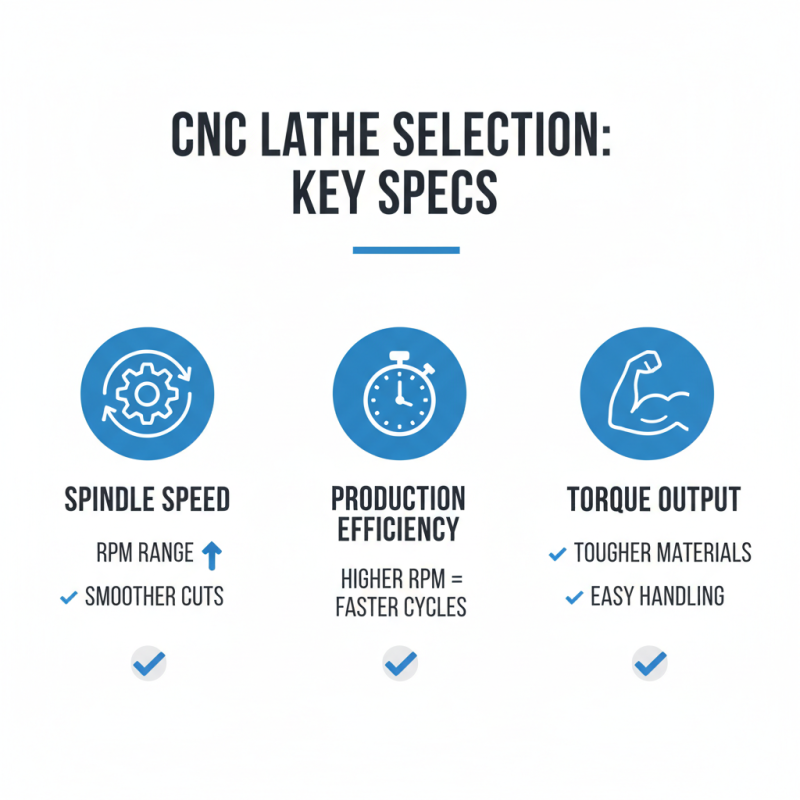

Evaluating CNC Lathe Specifications: Important Metrics to Analyze

When selecting a CNC lathe machine, analyzing specifications is crucial. Start with spindle speed. Higher speeds allow for smoother cuts and better materials handling. Measure the RPM range. This metric directly impacts production efficiency. Pay attention to the torque output as well. A machine with sufficient torque can handle tougher materials with ease.

Next, consider the axis configuration. Many lathes come with standard two or three-axis setups. Depending on your projects, a more complex system may be beneficial. Five-axis machines offer greater flexibility but require more skill to operate. Assess your workshop’s needs carefully. Sometimes a simpler machine suffices.

Another point to reflect on is machine weight. Heavier lathes tend to be more stable, yet they may limit mobility in your workshop. An ideal balance is essential. Look closely at the control system as well. User-friendly interfaces reduce errors but can vary widely. Finding what works for you often requires trial and error. This reflection is a vital part of fine-tuning your choices.

Budgeting for Your CNC Lathe Purchase: Costs and ROI Expectations

When budgeting for a CNC lathe, consider initial costs carefully. A quality CNC lathe can range from $10,000 to over $100,000. Factors include size, capability, and features. It's crucial to assess your workshop needs before making a purchase. Investing too little may lead to inadequate machinery. Conversely, overspending on features you won’t use is wasteful.

ROI is another key component. Industry reports suggest a well-selected CNC lathe can yield a return of 20-30% annually. Think about job costing and production volume. Higher output can justify a larger expense. However, be wary. Hidden costs like maintenance can erode profits. It’s important to project realistic operational expectations.

Consider not just the purchase price, but also training costs. Sometimes, effective utilization requires additional training sessions. If your staff isn’t skilled, you may not see returns. Reflect on how your current workflow can adapt. Effective integration of the machine is essential for realizing its full potential. The best investment isn’t always the most expensive one. It’s about finding the right fit for your workshop's specific operations.

How to Choose the Best CNC Lathe Machine for Your Workshop? - Budgeting for Your CNC Lathe Purchase: Costs and ROI Expectations

| Feature | Entry-Level CNC Lathe | Mid-Range CNC Lathe | High-End CNC Lathe |

|---|---|---|---|

| Price Range | $5,000 - $15,000 | $15,000 - $40,000 | $40,000 - $100,000 |

| Max Spindle Speed | 2500 RPM | 4000 RPM | 6000 RPM |

| Duty Cycle | 10 Hours/Week | 20 Hours/Week | 40 Hours/Week |

| Material Compatibility | Aluminum, Plastic | Aluminum, Plastic, Steel | Aluminum, Plastic, Steel, Titanium |

| Expected ROI Period | 2 years | 1.5 years | 1 year |

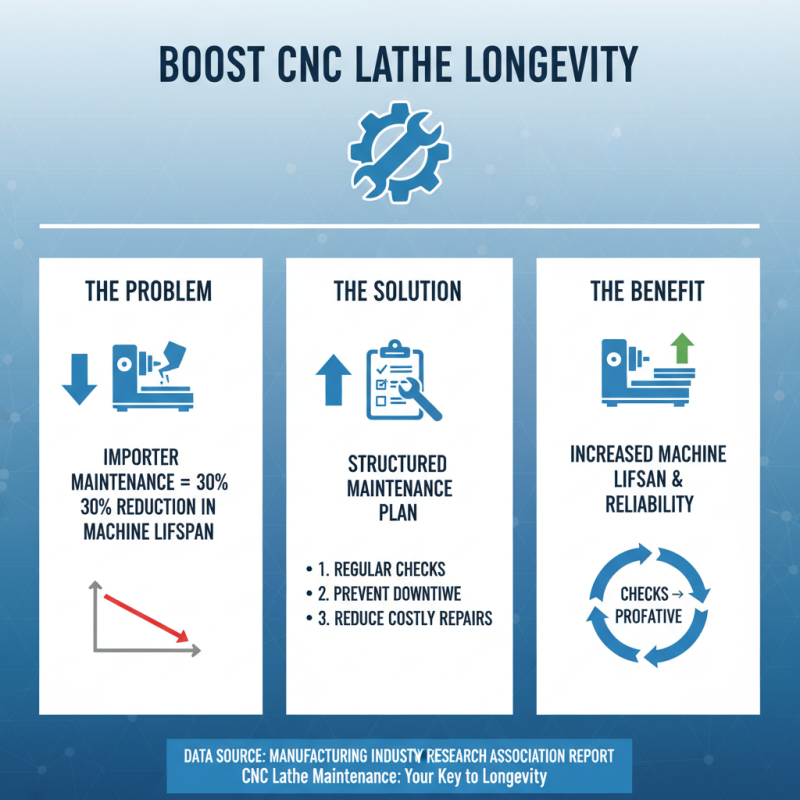

Maintenance and Support: Ensuring Longevity of Your CNC Lathe Machine

Maintenance is a crucial factor in ensuring the longevity of your CNC lathe machine. Regular checks can prevent costly downtime and repairs. According to a report from the Manufacturing Industry Research Association, improper maintenance can lead to a 30% reduction in machine lifespan. This emphasizes the importance of a structured maintenance plan.

Routine tasks should include cleaning, lubricating, and inspecting key components. Pay attention to the spindle and tool holder. These areas often accumulate debris, which can affect performance. A staggering 40% of CNC machine failures are attributed to poor maintenance practices, as noted in a study by CNC Insights.

Additionally, having a reliable support system is essential. Training staff on proper usage and maintenance protocols can eliminate common mistakes. It's important to create a feedback loop for operators to report issues promptly. Ignoring small problems can lead to larger failures. Making minor adjustments today can save significant costs tomorrow.

Related Posts

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

2026 Best Valve Seat Boring Machine Options to Consider?