How to Choose the Right Cylinder Boring Machine for Your Needs?

Choosing the right Cylinder Boring Machine is essential for efficient machining. The decision affects your productivity, costs, and the quality of your work. Various options exist in the market, each with unique features.

Understanding your specific needs is crucial. Consider factors like engine size, materials, and volume of work. Some machines excel with aluminum, while others are better for cast iron. Be mindful of budget limitations. The highest price doesn’t always guarantee the best performance.

Evaluate both new and used machines. Sometimes, a pre-owned Cylinder Boring Machine might suit your requirements better than a brand-new model. Explore customer reviews and expert opinions too. Seek feedback from experienced users. This reflection can guide you in making an informed choice.

Importance of Cylinder Boring Machines in Engine Overhaul Projects

Cylinder boring machines play a critical role in engine overhaul projects. They ensure precise cylinder dimensions and restore engine performance. When engines wear down, these machines can rejuvenate them. Many engines suffer from irregular wear. A quality cylinder boring machine fixes this by machining the cylinder to a uniform size. A well-bored cylinder improves the fit for pistons and enhances compression. This leads to better fuel efficiency and power output.

Tips: Always check the machine's spindle speed. Higher speeds may reduce cutting time but can affect accuracy. Take note of machine weight, too. Heavier machines usually offer better stability during operation.

Choosing the right machine can be tough. Consider the range of cylinder sizes you will work with. Some machines only handle specific sizes. Think about long-term needs, not just immediate projects. A machine that fits today’s needs may fall short tomorrow. Assessing your specifics is key. Ask yourself, "Will this meet my future needs?" Engine overhaul requires precision. Cutting corners with equipment can lead to costly mistakes.

Importance of Cylinder Boring Machines in Engine Overhaul Projects

Key Specifications to Consider When Selecting a Cylinder Boring Machine

When selecting a cylinder boring machine, several key specifications stand out. Pay attention to the machine's bore diameter capacity. Most machines can handle diameters ranging from 40 mm to over 300 mm. This variance greatly impacts the scope of work. For instance, a machine with a larger capacity can accommodate larger engine blocks, potentially increasing job opportunities. However, if your focus is on smaller applications, a more compact machine may suffice.

Another important specification is precision. According to industry reports, precision can be affected by machine rigidity and the quality of tooling. A rigid machine reduces vibration, which enhances accuracy. Look for machines with tolerance levels of 0.005 mm or better. It's essential to weigh the benefits of higher precision against budget constraints. A more precise machine often means a higher initial investment.

Lastly, consider the ease of use and maintenance. Some machines have user-friendly interfaces, while others may require specialized training. Maintenance can include regular calibration and part replacements, which are crucial for optimal performance. Research shows that machines with lower maintenance needs often lead to higher productivity. Balancing these aspects is vital for a successful purchase.

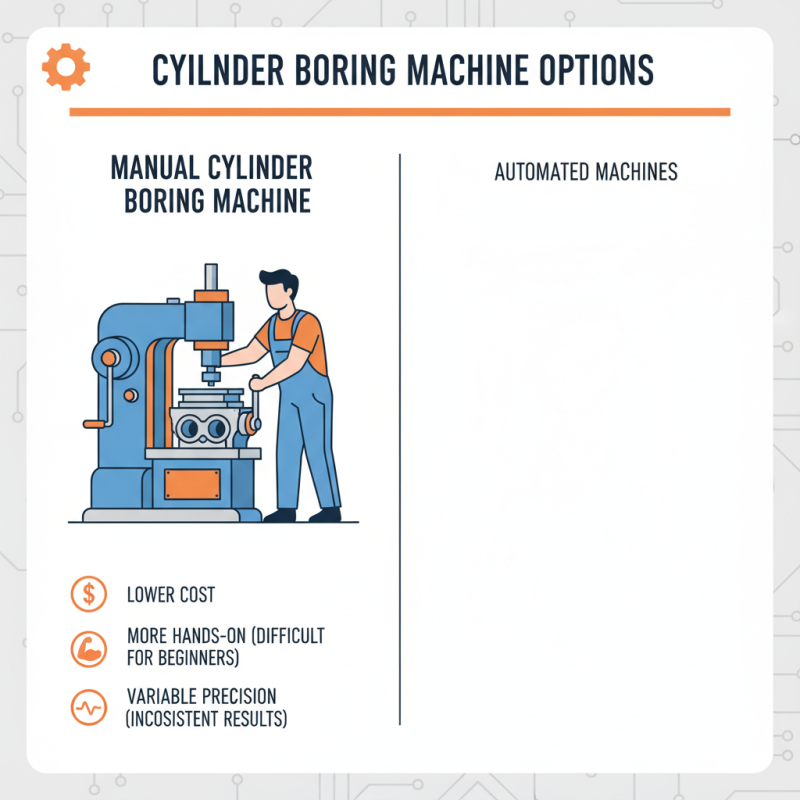

Analyzing Different Types of Cylinder Boring Machines on the Market

When it comes to choosing a cylinder boring machine, options abound. You may find manual machines that require more hands-on involvement. These are often less expensive and good for small operations. However, they can be challenging to use, especially for beginners. Precision also tends to vary with manual devices, leading to inconsistent results.

On the other hand, automatic and semi-automatic machines offer greater precision and user-friendliness. They can significantly reduce labor time and improve accuracy. Yet, these machines tend to be pricier. For small shops or hobbyists, this could be a serious consideration. A well-placed question is whether the investment will pay off in the long run.

When evaluating machines, consider your specific needs. How often will you use it? What types of cylinders will you work on? Each machine has unique specifications that may or may not meet your requirements. Balancing cost with performance is crucial. It’s advisable to start with the basics, and you can always upgrade later.

Evaluating Cost vs. Performance for Cylinder Boring Equipment Choices

When choosing a cylinder boring machine, evaluating cost against performance is crucial. Many machines come with various price tags, but a lower cost doesn’t always mean better value. The performance of the equipment must meet your specific needs. Look for machines that provide the right balance between price and features.

Consider essential aspects such as power, durability, and accuracy. A powerful machine may cost more, but it can handle tougher jobs. On the other hand, a less powerful option may be affordable but might struggle with heavy usage. It’s necessary to analyze whether the machine can maintain precision over time. Frequent calibration could lead to added costs and downtime.

Remember, investing in the right machine is more than just the initial cost. Think about maintenance expenses too. Some machines may seem cheaper at first but can become expensive over time. User reviews can help, but they can also be misleading. Take your time, compare models, and think about your specific needs. Consider how often you'll use it and in what capacity. These elements are vital for making an informed choice.

How to Choose the Right Cylinder Boring Machine for Your Needs?

| Model | Cost ($) | Boring Diameter (inches) | Max Depth (inches) | Power (HP) | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | $5,000 | 2.5 | 5.0 | 10 | 300 |

| Model B | $6,500 | 3.0 | 6.0 | 15 | 350 |

| Model C | $7,800 | 3.5 | 7.0 | 20 | 400 |

| Model D | $9,200 | 4.0 | 8.0 | 25 | 450 |

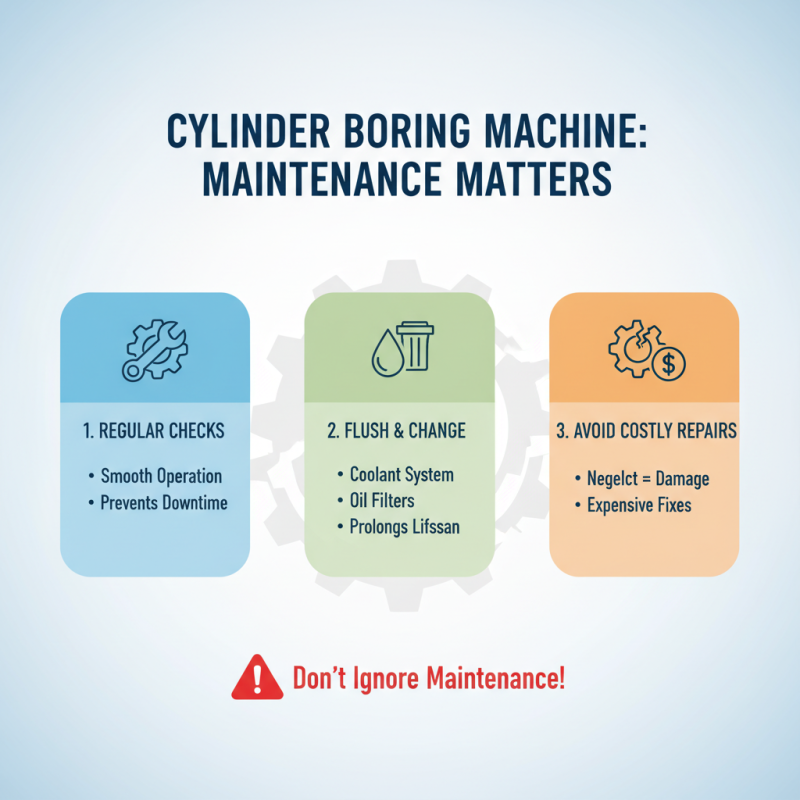

Understanding Maintenance and Support for Your Cylinder Boring Machine

Choosing the right cylinder boring machine involves more than just specifications. Maintenance is key. Regular checks ensure the machine runs smoothly. Flushing coolant and changing filters prolongs life. Ignoring these tasks can lead to costly repairs later.

Support matters too. Find resources that provide troubleshooting guides. Online forums often help resolve common issues. Connecting with other users can yield hidden tips. Consider investing in a service plan. This may be reassuring if something goes wrong. It's crucial to have access to qualified technicians.

User feedback is valuable in assessing maintenance needs. Assess how often you'll use the machine. Daily use requires stricter maintenance routines. Less frequent use may call for a simpler approach. Don't overlook the importance of manufacturer documentation. It often includes maintenance schedules and support resources. Balancing these elements can lead to a more effective choice.

Related Posts

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs

-

Why Choose a Sheet Metal Shearing Machine for Your Business Needs

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry