How to Choose the Best Profile Bending Machine for Your Metalworking Needs

In the metalworking industry, precision and efficiency are paramount, making the choice of machinery a critical factor in achieving success. One of the essential pieces of equipment for fabricating metal components is the Profile Bending Machine. According to recent industry reports, the global market for bending machines is expected to grow significantly, driven by the increasing demand for customized metal profiles in construction, automotive, and manufacturing sectors. As businesses strive to enhance their operational capabilities, understanding how to select the best Profile Bending Machine becomes essential for optimizing production processes and maintaining a competitive edge.

Selecting the right Profile Bending Machine involves considering various factors such as the machine's specifications, bending capacity, and ease of use. Industry experts stress the importance of assessing the material types and thicknesses that will be processed, as well as the complexity of the profiles required. A well-chosen Profile Bending Machine not only increases efficiency but also ensures higher quality in the finished products, leading to enhanced customer satisfaction and reduced rework. As the metalworking landscape continues to evolve, making informed decisions about machinery can significantly impact overall business performance and growth.

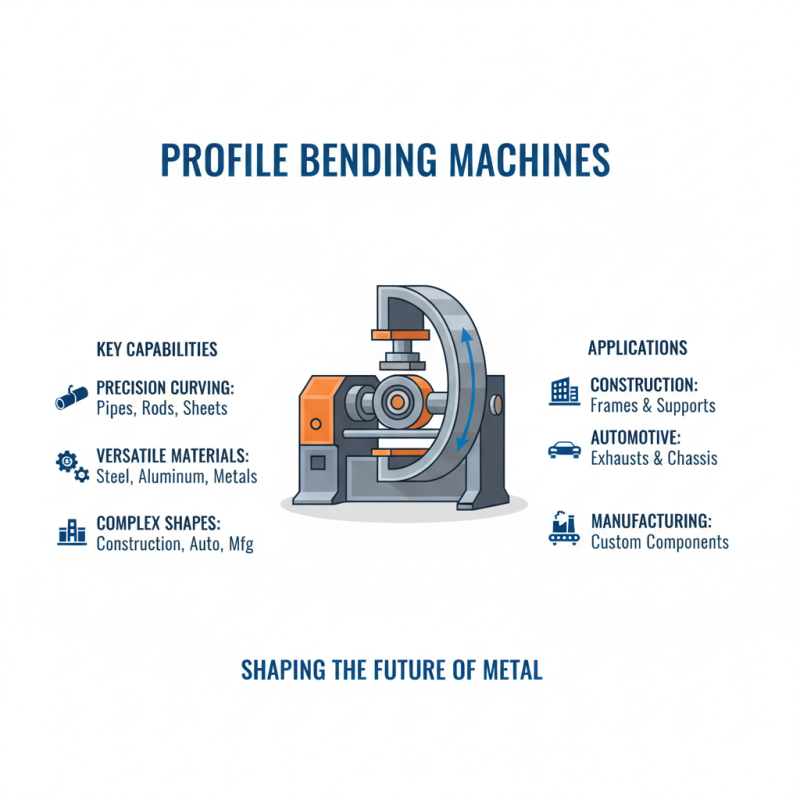

Understanding Profile Bending Machines and Their Applications

Profile bending machines are essential tools in metalworking, designed to create precise curves and shapes in various materials, including steel, aluminum, and other metals. These machines can bend metal profiles such as pipes, rods, and sheets into complex configurations suitable for applications in construction, automotive, and manufacturing industries. Understanding the capabilities and limitations of profile bending machines is crucial for selecting the right one for your specific needs.

When choosing a profile bending machine, consider the types of materials you’ll be working with and the complexity of the bends required. Different machines are suited for different profile shapes and thicknesses. A machine with adjustable parameters can provide versatility for a range of projects, from simple bends to intricate designs. Furthermore, ensure the machine can accommodate the volume of production you anticipate, as performance can vary significantly between models.

**Tips**: Start by assessing the maximum diameter and thickness of the metal you’ll be bending. Additionally, look for machines with user-friendly controls and safety features to enhance productivity and minimize risks during operation. Finally, consider machines that offer good customer support and warranties, ensuring you're well-equipped for any future maintenance needs.

Key Factors to Consider When Choosing a Profile Bending Machine

When selecting the best profile bending machine for metalworking needs, several key factors come into play to ensure optimal performance and efficiency. One primary consideration is the machine's capacity, which typically ranges from bending radii as small as 1.5 times the material's thickness to larger, more complex shapes. According to a recent industry report by the Machinery Manufacturers Institute, a machine’s bending capacity can significantly affect productivity, with larger capacity machines reporting up to 30% more efficiency in production compared to their smaller counterparts.

Another crucial aspect is the material type and thickness that the machine can handle. Different bending machines are designed to accommodate various materials like aluminum, steel, or stainless steel. Data from the National Association of Manufacturers indicates that selecting a machine configured for specific materials can extend tool life by up to 25%, reducing downtime and maintenance costs. Moreover, evaluating features such as CNC control options and ease of setup can greatly influence operation speed. Machines equipped with advanced controls allow for precision bending capabilities that can reduce errors and material wastage, supporting manufacturers in achieving higher quality outputs.

Lastly, considering the overall size, portability, and power requirements of the machine can also impact decision-making. According to a survey conducted by the Fabricators and Manufacturers Association, over 60% of shops preferred machines that offered a balance between portability and high output, ensuring they can meet diverse project demands while maintaining flexibility in their operations. By attentively assessing these factors, manufacturers can invest in a profile bending machine that aligns with their production goals and operational needs.

How to Choose the Best Profile Bending Machine for Your Metalworking Needs - Key Factors to Consider When Choosing a Profile Bending Machine

| Key Factors | Description | Importance Level | Example Specifications |

|---|---|---|---|

| Bending Capacity | The maximum thickness and width of materials that can be bent. | High | Up to 20 mm thickness, 300 mm width |

| Bending Radius | The minimum and maximum radius for bending operations. | Medium | Minimum 50 mm, Maximum 300 mm |

| Machine Size | The overall dimensions of the machine, affecting workspace requirements. | Low | Length: 3000 mm, Width: 1500 mm, Height: 1200 mm |

| Control System | The type of control for operating the bending machine, such as manual or automated. | High | CNC control with programmable settings |

| Power Source | The electrical specifications and consumption of the bending machinery. | Medium | 380V, 50Hz, 15 kW |

| Cost | The total price of the machine, including setup and potential hidden costs. | High | $15,000 - $40,000 |

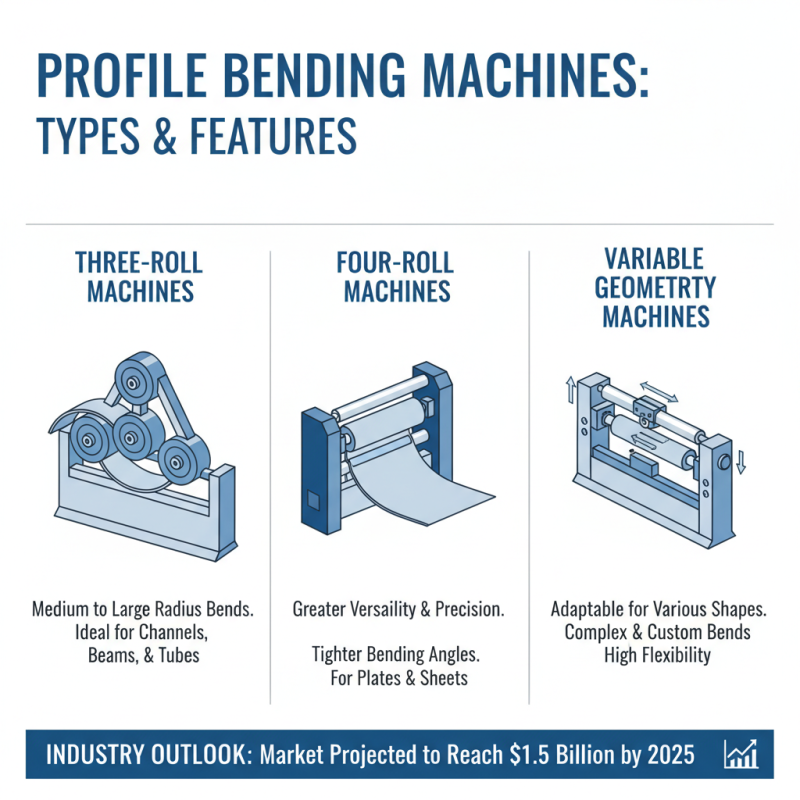

Types of Profile Bending Machines and Their Features

When selecting a profile bending machine for metalworking needs, it's crucial to understand the different types available and their specific features. Profile bending machines primarily fall into three categories: three-roll machines, four-roll machines, and variable geometry machines. Each type is designed for particular tasks, with three-roll machines being ideal for producing medium to large radius bends, while four-roll machines offer greater versatility and precision for tighter bending angles. According to a recent industry report by Research and Markets, the market for bending machines is projected to reach USD 1.5 billion by 2025, highlighting the demand and showcasing advancements in machine technology.

Three-roll machines typically operate by positioning materials between three rollers, which exert pressure to create bends. They are favored for their robustness and simplicity, making them suitable for standard operations in construction and manufacturing. Conversely, four-roll machines incorporate an additional roller to provide more control over the bending process, particularly beneficial for high-precision applications in industries such as aerospace and automotive. The variable geometry machines, on the other hand, allow for adapting roller positions according to the workpiece's specific requirements, enabling complex shapes and profiles to be produced efficiently. A detailed analysis by Global Industry Analysts emphasizes that the flexibility and operational efficiency of these machines are key drivers for their growing adoption in diverse sectors.

Understanding these features and how they align with production needs is essential for selecting the best profile bending machine. Decision-makers should consider not only the technological specifications but also the intended applications, as the right choice can significantly enhance productivity and quality in metalworking operations.

Evaluating Your Metalworking Needs for Optimal Machine Selection

When selecting the best profile bending machine for your metalworking needs, the first step is to thoroughly evaluate your specific requirements. A key factor in this assessment is the type of materials you will be working with. According to a report from the Metal Forming Industry Association, the demand for bending machines capable of processing various materials, including steel, aluminum, and specialty alloys, has increased by over 15% in the last few years. Understanding the tensile strength and ductility of these materials will guide you in choosing a machine with the appropriate capabilities, ensuring optimal performance and longevity.

Additionally, consider the volume and frequency of your projects. If your operations require high production rates, investing in a machine with automatic features and faster cycle times can lead to increased efficiency. The Fabricators & Manufacturers Association International reported that manufacturers using advanced profile bending technology have seen productivity gains of up to 30%. This highlights the importance of aligning your machine choice with anticipated workloads. By thoroughly assessing these elements—material specifications and production demands—you can strategically select a profile bending machine that not only meets your immediate needs but also positions your operation for future growth.

Cost-Benefit Analysis of Profile Bending Machines for Your Business

When considering the acquisition of a profile bending machine, performing a cost-benefit analysis is essential for determining its impact on your metalworking business. According to a report by Research and Markets, the global market for profile bending machines is projected to grow by over 5% annually, driven by the increasing demand in sectors such as construction, automotive, and shipbuilding. This growth highlights the importance of investing in high-quality machinery that can enhance operational efficiency and adaptability, resulting in better project outcomes.

Investing in a profile bending machine often leads to significant long-term savings. For instance, a well-selected machine can reduce labor costs and processing time by as much as 30% compared to traditional methods. Furthermore, the Precision Metalforming Association indicates that advanced bending technology can minimize material wastage by up to 15%, which directly enhances profit margins. By evaluating both the initial investment costs and the potential operational savings, businesses can make informed decisions that align with their financial goals and growth strategies. Ultimately, understanding these metrics helps companies allocate resources effectively and remain competitive in an evolving market.

Related Posts

-

2025 Top Universal Milling Machine Features and Buying Guide

-

How to Choose the Right Universal Milling Machine for Your Needs

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry