How to Choose the Right Universal Milling Machine for Your Needs

Choosing the right Universal Milling Machine for your specific needs can be a daunting task given the range of options available on the market today. According to industry expert John Smith, a renowned milling technology specialist, "Selecting the appropriate milling machine is crucial for optimizing both efficiency and precision in manufacturing processes." This statement underlines the importance of understanding your operational requirements before making a purchase.

Universal Milling Machines are versatile tools that play a vital role in modern machining. They offer a wide range of functionalities, making them suitable for complex tasks that require precision and adaptability. However, with so many models and features, it can be challenging for manufacturers to determine which machine aligns perfectly with their production goals. A thoughtful assessment of factors such as machining capabilities, size, and operational efficiency is essential in ensuring you make an informed decision.

As we delve deeper into the intricacies of Universal Milling Machines, we will explore critical considerations that can guide you in selecting the right machine tailored to your unique operational demands. By understanding the various aspects outlined in this guide, you will be better equipped to navigate the complexities of milling technology and select a machine that enhances your production capabilities.

Factors to Consider When Selecting a Universal Milling Machine

When selecting a universal milling machine, there are several crucial factors to consider to ensure you choose the right one for your specific needs.

First, assess the machine's size and the space you have available in your workshop. A larger machine can handle more complex jobs but requires adequate space for operation and maintenance. Ensure that the dimensions of the milling machine fit comfortably within your workspace to maximize efficiency.

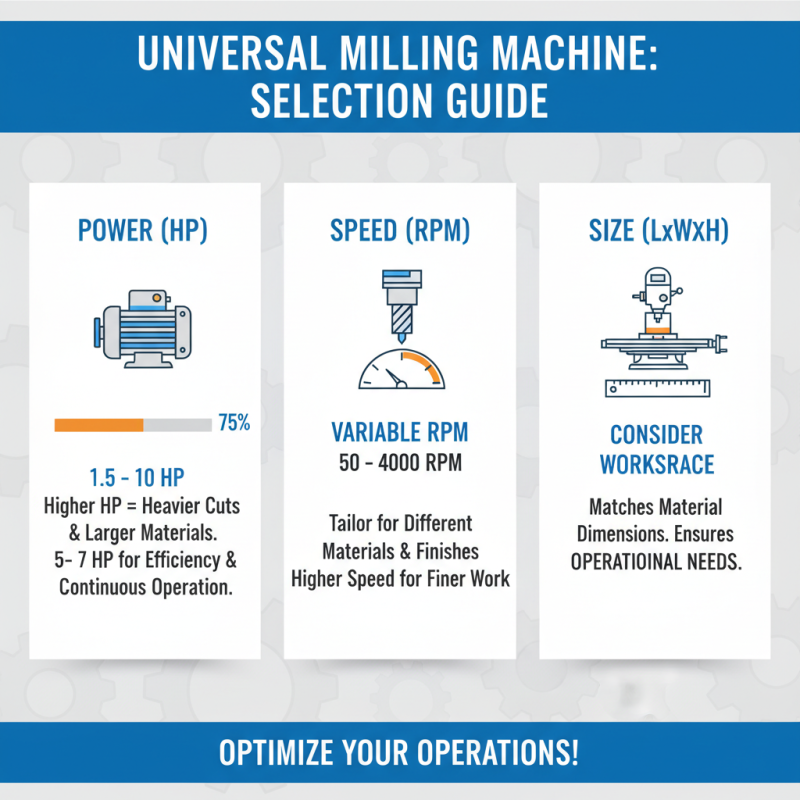

Another important factor is the machine’s power and speed capabilities. The horsepower and RPM range will determine the types of materials you can work with and the complexity of the milling tasks you can perform. For more demanding jobs, a machine with higher power and variable speed settings can provide greater versatility.

Tips: Always check the specifications for the milling machine’s maximum table size and weight capacity, as this will affect the types of projects you can undertake. Additionally, consider machines with robust safety features to prevent accidents and ensure a safe working environment.

Moreover, it’s essential to look into the availability of parts and service support for the machine you choose. A reliable source for maintenance and repairs can save you time and money in the long run. Researching user reviews and recommendations can also provide insight into the machine’s performance and ease of use, helping you make a more informed decision.

Types of Universal Milling Machines and Their Applications

When selecting a universal milling machine, it's vital to consider the various types available and their specific applications. The most common types of universal milling machines include horizontal, vertical, and combination machines.

Horizontal milling machines are suitable for producing complex parts and are often used in heavy-duty applications due to their robust design. According to a report by Market Research Future, the horizontal milling machine segment is expected to account for over 35% of the market share by 2025, reflecting its strong demand in industries such as aerospace and automotive.

Vertical milling machines, on the other hand, are favored for their versatility and precision. They are ideal for tasks requiring fine detail and are extensively used in manufacturing prototypes and small to medium-sized batches. A study by Technavio indicates that the vertical milling machine segment is projected to grow at a CAGR of 3.5% through 2024, largely driven by advancements in technology that enhance machining accuracy and efficiency.

Combination milling machines, which offer both horizontal and vertical capabilities, are particularly popular in smaller shops where space and budget constraints are critical. This adaptability makes them a valuable choice for businesses looking to maximize production flexibility without investing in multiple machines.

Key Specifications: Power, Speed, and Size Requirements

When selecting a universal milling machine, understanding key specifications such as power, speed, and size requirements is crucial to ensure it meets your operational needs. Power is often a primary consideration, with most universal milling machines featuring motors ranging from 1.5 to 10 horsepower. According to industry reports, machines with higher horsepower capabilities allow for more aggressive cutting operations, making them suitable for larger materials and more complex milling tasks. For instance, a machine with 5-7 horsepower can generally handle heavier materials and provide better efficiency during continuous operation.

In addition to power, the speed of the milling machine plays a significant role in defining its versatility. The majority of universal milling machines offer variable speed options, typically between 60 to 3,000 RPM. This variability is essential as it allows operators to adjust the speed according to the material and the type of milling being performed. Recent studies highlight that machines with a broader range of RPM settings can improve overall production rates by accommodating various cutting tools and techniques.

Finally, size requirements must align with both workspace availability and the scale of operations. Most universal milling machines have table sizes ranging from 400 mm to over 2,000 mm, which directly affects the machine's capacity to handle workpieces of different dimensions. Industry analyses suggest that selecting a machine with an appropriately sized table not only facilitates efficient workflow but also ensures safety during operation. Therefore, assessing these specifications—power, speed, and size—will greatly influence the effectiveness and productivity of your milling processes.

Understanding the Importance of Build Quality and Precision

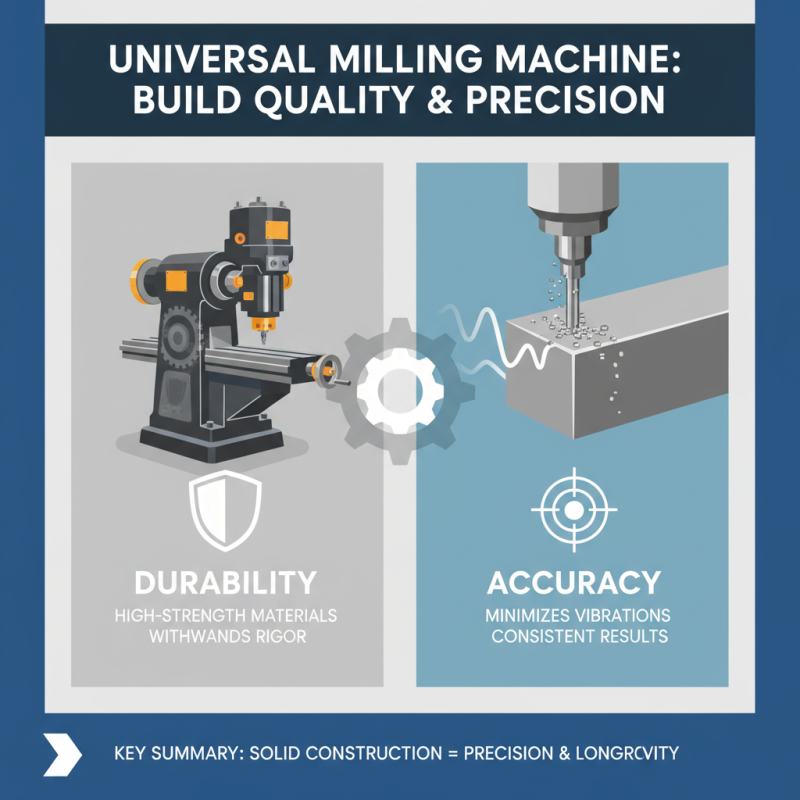

When selecting a universal milling machine, understanding the importance of build quality and precision is paramount. A well-constructed machine not only enhances durability but also plays a crucial role in maintaining consistent results. Solid construction minimizes vibrations, which can compromise the accuracy of machining processes. Look for machines made from high-strength materials that can withstand the rigors of repetitive milling tasks.

Tips: Always inspect the machine's components, such as the bed, spindle, and table, for any signs of wear or potential weaknesses. A thorough understanding of the machine's structure ensures that you choose a unit that meets your operational demands.

Precision is equally crucial, as it directly affects the quality of your finished products. Machines with tight tolerances allow for more intricate designs and finer finishes, reducing the need for additional machining processes. Consider models with advanced controls that facilitate high precision movements to ensure every cut is executed flawlessly.

Tips: When assessing precision, review the specifications regarding the machine’s maximum feed rate and cutting speeds. These factors will inform you about its capability to deliver precise results across various materials and applications.

Budgeting for Your Universal Milling Machine Purchase: Costs and ROI

When considering the purchase of a universal milling machine, budgeting is a crucial component that directly influences your investment. Begin by determining the overall costs associated with the machine, including initial purchase price, operational expenses, and maintenance. The price can vary significantly based on the machine’s capabilities, size, and features. It's essential to account for these factors while setting your budget, as overlooking hidden costs can impact your financial planning.

In addition to the upfront costs, evaluating the potential return on investment (ROI) is vital. A well-chosen milling machine should boost productivity and enhance manufacturing precision, which can lead to increased efficiency and profitability. Consider how the machine will integrate into your existing operations and what improvements it can bring to your workflow. Calculating the expected gains from reduced labor costs, shorter production times, and enhanced output quality will help you assess whether the initial investment is justified. Analyzing both costs and potential ROI will guide you in making an informed decision that aligns with your operational needs and financial objectives.

How to Choose the Right Universal Milling Machine for Your Needs - Budgeting for Your Universal Milling Machine Purchase: Costs and ROI

| Feature | Importance Rating (1-5) | Average Cost ($) | Estimated ROI (%) |

|---|---|---|---|

| Machine Size | 4 | 5,000 | 15% |

| Power Supply | 3 | 4,000 | 20% |

| Tooling Versatility | 5 | 6,500 | 25% |

| Ease of Use | 4 | 3,500 | 18% |

| Maintenance Requirements | 5 | 4,500 | 22% |

Related Posts

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

2025 Top Universal Milling Machine Features and Buying Guide

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs