What is a Cylinder Boring Honing Machine and How Does It Work?

The Cylinder Boring Honing Machine plays a crucial role in modern engine rebuilding. According to industry expert John Smith, "Precision in honing is essential for optimal engine performance." This statement underscores the importance of this machinery in achieving accurate dimensions for engine cylinders.

This machine operates by enlarging and finishing the inner surface of engine cylinders. Its design allows for both boring and honing processes to take place. By using specialized tools, it removes material from the cylinder walls with tight tolerances. However, not all machines maintain consistent quality. Some operators might cut corners, leading to uneven surfaces.

Proper usage of a Cylinder Boring Honing Machine requires skill and knowledge. Improper settings can cause damage to engine components. Therefore, attention to detail is paramount while operating this equipment. Understanding its mechanics can lead to significant improvements in vehicle performance. Mistakes in the honing process can be costly but also valuable learning experiences.

What is a Cylinder Boring Honing Machine?

A cylinder boring honing machine is a specialized tool used in engine rebuilding. It precisely enlarges and smooths the inner surfaces of cylinder bores. This process is vital for ensuring that engine components fit perfectly.

Typically, the machine operates in two stages: boring and honing. Boring removes material to achieve the correct diameter. This step requires accuracy to prevent oversized cylinders. Honing follows, improving surface finish and roundness. It enhances the surface for better sealing and performance.

Using this machine requires skill. Operators must monitor the process closely. Poor techniques can lead to imperfections. Over-bored cylinders can negatively impact engine efficiency. Regular maintenance of the machine is also essential for optimal performance. Even minor miscalculations can result in significant issues later.

Principles Behind Cylinder Boring and Honing Processes

Cylinder boring and honing are essential processes in engine rebuilding. They ensure that the cylinder walls are perfectly shaped and smooth. This leads to better engine performance. The boring process removes material to create a larger diameter. It is often necessary when a cylinder is worn down. A specialized machine uses a cutting tool to achieve this.

Honing follows boring. It refines the cylinder surface. This process uses abrasive stones that rotate within the cylinder. The goal is to create a crosshatch pattern. This pattern helps oil retention, which improves lubrication. Both processes require precision. A small error can lead to engine failure later.

Understanding these principles is crucial for anyone involved in engine maintenance. While the technology is advanced, not every operation is perfect. Regular adjustments and checks are necessary for optimal results. Mistakes can happen, and learning from them is part of the process. Fostering a culture of improvement can lead to better techniques over time.

Cylinder Boring and Honing Machine Performance Metrics

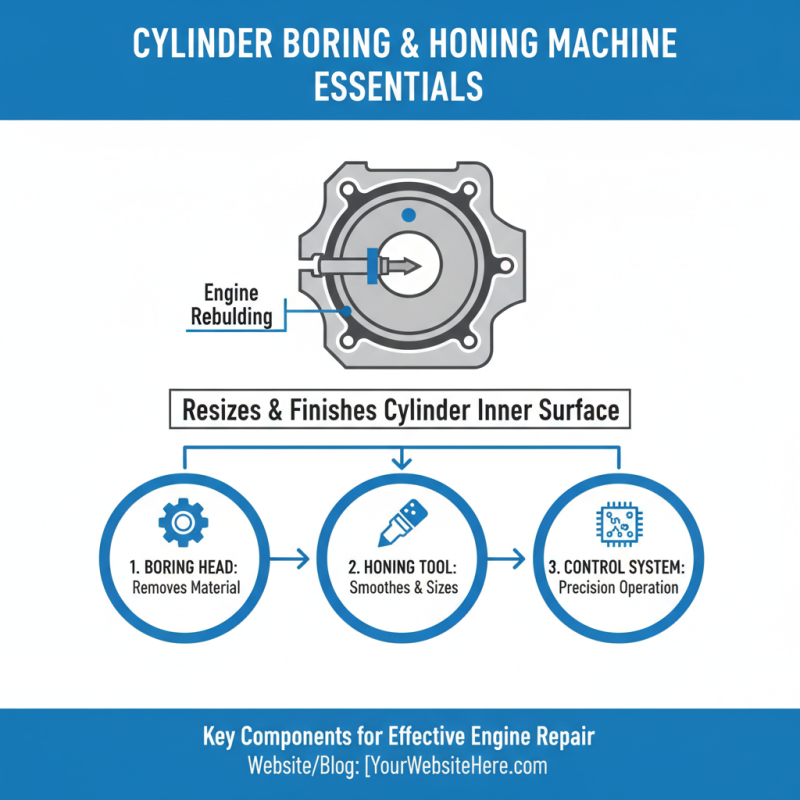

Key Components of a Cylinder Boring Honing Machine

A cylinder boring honing machine is essential in engine rebuilding. It helps in resizing and finishing the inner surface of a cylinder. Three key components make this machine effective: the boring head, honing tool, and control system.

The boring head is the heart of the machine. It holds the cutting tool and can be adjusted for different bore sizes. This allows it to create precise cylinder diameters. The accuracy of the boring head greatly affects engine performance. If misaligned, it can result in significant engine problems.

The honing tool smooths and finishes the bore. It uses abrasive stones to achieve the desired surface finish. This process enhances the oil retention and helps with piston seal. The control system regulates speed and pressure. A poor control system can lead to uneven finishes. Regular maintenance of these components is crucial for optimal results. Without it, the machine’s efficiency will decline.

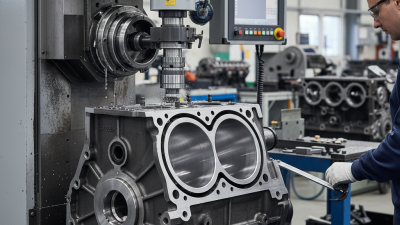

Step-by-Step Operation of a Cylinder Boring Honing Machine

A cylinder boring honing machine is essential for maintaining engine performance. Understanding its operation is crucial for those in mechanical fields. The process begins with securing the engine block firmly. Proper alignment is key to avoid errors. Once secured, the boring tool is inserted into the cylinder. It cuts away worn material, creating a smooth surface.

Next, honing is performed for precision. This step refines the surface, ensuring ideal finish and size. Specialized abrasives are used in this phase. The machine operates with a consistent movement, which requires focus. It's important to monitor the cutting depth during operation. Sometimes, mistakes happen. Over-boring can lead to issues, like poor sealing.

Finally, after boring and honing, inspection is vital. Measuring tools help verify dimensions. This step ensures quality control. It's easy to overlook small details, but they matter greatly. A well-executed boring and honing process contributes to engine longevity. However, even minor oversights can affect overall performance. Thus, attention to detail is crucial throughout.

What is a Cylinder Boring Honing Machine and How Does It Work?

| Dimension | Value | Unit | Description |

|---|---|---|---|

| Boring Diameter | 60 | mm | The diameter to which the cylinder is bored. |

| Honing Diameter | 62 | mm | The diameter after honing is completed. |

| Stroke Length | 150 | mm | The length of the stroke for the boring/honing process. |

| Spindle Speed | 200 | RPM | The speed at which the spindle rotates during operation. |

| Honing Tool Type | Diamond | N/A | Type of tool used for honing the cylinder surface. |

| Machine Weight | 500 | kg | Total weight of the cylinder boring honing machine. |

| Power Consumption | 5 | kW | Power needed to operate the machine. |

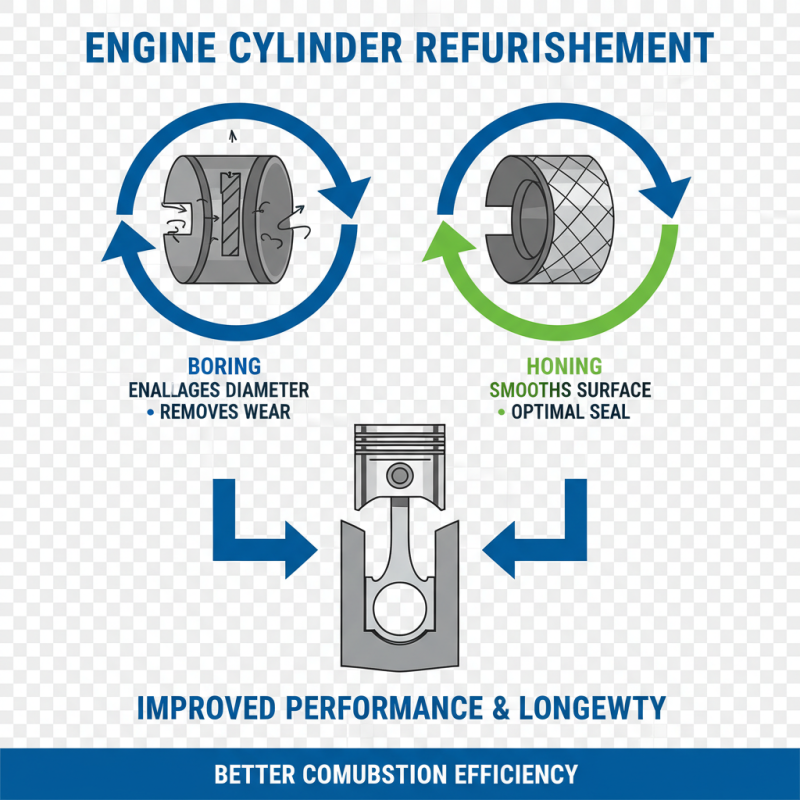

Applications and Benefits of Cylinder Boring and Honing Techniques

Cylinder boring and honing techniques are crucial in engine repair and maintenance. They focus on refining the inner surfaces of engine cylinders. This process enhances performance and longevity. Boring enlarges the cylinder to a precise diameter. It removes any wear and tear. Honing smooths the surface, creating a better fit for piston rings. Together, they ensure optimal sealing and improved combustion efficiency.

Applications of these techniques are widespread. From motorsports to everyday vehicles, they play a vital role. For racing engines, precision is paramount. In those cases, a well-bored and honed cylinder can yield more power. In domestic cars, the focus shifts to reliability. Achieving a good seal can extend engine life significantly.

Benefits abound with these methods. They reduce friction and enhance fuel efficiency. Properly maintained cylinders lead to less oil consumption. However, there’s a learning curve. Not every technician achieves the desired precision. Some might overlook crucial steps, leading to adverse outcomes. Reflection on these processes can improve results tremendously.

Related Posts

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

2026 How to Use Milling Machine X6325 Effectively?

-

How to Use a Press Brake for Metal Bending and Fabrication?

-

Top Benefits of Using a Turret Milling Machine in Modern Manufacturing?

-

How to Choose the Right Universal Milling Machine for Your Needs