Top 10 Essential Features of a Milling Machine X6325 for Your Workshop?

In any workshop, the Milling Machine X6325 stands out as a crucial tool. This versatile machine offers precision and efficiency. Its features make it an ideal choice for various milling tasks.

Many workshops struggle with choosing the right milling machine. The Milling Machine X6325 simplifies this process. It combines practicality with advanced technology. Yet, understanding its essential features is not always easy. Some may overlook key attributes that enhance performance.

Consider the power of its motor, the precision of its spindle, and the stability of its base. These features are essential for efficient milling. However, not all users fully utilize them. A lack of knowledge can lead to missed opportunities for improvement. The Milling Machine X6325 can transform your projects if you leverage its capabilities effectively.

Key Specifications to Look for in a Milling Machine X6325

When considering a milling machine like the X6325, pay attention to key specifications. The spindle speed is crucial. Most machines in its class offer a range from 60 to 3000 RPM, enabling versatile machining capabilities. The higher the RPM, the finer the finish you can achieve. However, there can be drawbacks. For example, excessive speeds may lead to tool wear or overheating.

Another important specification is the table size. A larger table, around 1250x250 mm, enhances capacity for larger workpieces. However, bigger tables may lead to stability issues if the machine isn't well-engineered. Additionally, the weight of the milling machine often affects its vibration during operation. A machine weighing over 800 kg usually offers better performance due to reduced vibrations.

Lastly, look for features like power feed options and DRO systems. A power feed enables smoother operation, but not all machines come equipped with it. DRO, or digital readout systems, are excellent for precision work, yet they can add complexity. Selecting a milling machine involves navigating these trade-offs. Data from industry reports indicate that around 90% of users prioritize accuracy while overlooking the importance of milling machine stability.

Understanding the Importance of Milling Machine Versatility

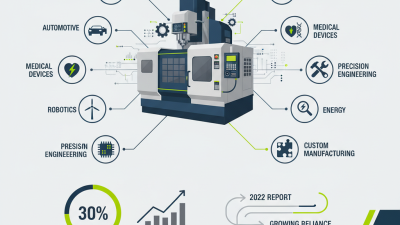

Milling machine versatility is crucial for any workshop. A versatile machine can perform various functions, increasing productivity. According to a recent industry report, workshops utilizing versatile milling machines saw a 30% increase in operational efficiency. This reinforces the importance of choosing the right features.

The X6325 milling machine is designed to adapt to different tasks. It allows users to switch between cutting, drilling, and shaping materials easily. Features like adjustable speed and multiple tool compatibility enhance this adaptability. Interestingly, 25% of machinists reported that a lack of versatility led to project delays. This reflects the reality of modern manufacturing needs.

Many operators underestimate the need for flexibility in their machines. Some stick to traditional methods, limiting their output. In contrast, the best workshops thrive on adaptability. They continuously assess machine capabilities. Keeping an eye on technological advancements is essential for long-term growth in any machining environment.

Top 10 Essential Features of a Milling Machine X6325 for Your Workshop

Top Safety Features to Consider for the X6325 Model

Safety should always be a priority when working with a milling machine like the X6325. This model offers several essential safety features that can significantly reduce risks. Operators should pay close attention to the emergency stop button. It's crucial for halting operations swiftly during emergencies. A well-placed emergency stop can prevent serious injuries.

Another important aspect is the machine's protective enclosures. Good enclosures limit access to moving parts and reduce exposure to flying debris. Operators must ensure these enclosures are always in place while the machine is running. Additionally, having a functional coolant system is vital. Proper coolant not only assists in achieving better finishes but also minimizes heat-related accidents.

Operators often overlook personal safety gear. Wearing protective eyewear and gloves is necessary but sometimes forgotten. Machine operation requires focus; sunglasses won’t cut it. It’s easy to slip into complacency. Regular training refreshers on operating protocols can help combat this issue. Operators should be encouraged to voice any safety concerns without hesitation.

Essential Tooling Options for Enhanced Performance

When enhancing the performance of a milling machine like the X6325, tooling options play a crucial role. You need to choose the right cutting tools based on your projects. End mills, drill bits, and face mills are vital for various applications. These tools can significantly affect accuracy and finish quality. An end mill with the correct geometry can provide better chip removal and smoother cuts.

Moreover, consider tool material. High-speed steel and carbide options offer different benefits. Carbide tools tend to last longer but can be more fragile. Using the proper tool material based on your material type can prevent wear and tear. Sometimes, trial and error is necessary to find the best fit. Pay attention to tool wear indicators; they often reveal more than you expect.

Another essential aspect is tool setup. Proper alignment and installation can greatly impact performance. Yet, many overlook this step. A misaligned tool can lead to inaccuracies. Regular checks help ensure better results. Investing time in these details promotes consistent, high-quality work. It’s a continuous learning process that requires patience and adjustment.

Maintenance Tips for Longevity of Your X6325 Milling Machine

Maintaining your X6325 milling machine ensures optimal performance. Regular maintenance extends the life of the machine and saves money in the long run. A clean machine runs better. Dust and chips can wear down parts if not cleaned. Make it a habit to clean after each use.

Oil and lubricate moving parts routinely. Use the right lubricants to reduce friction. Check machine manuals for specific oil types. Insufficient lubrication can lead to malfunctions. Sometimes users forget this step, creating future headaches.

Keep an eye on components. Check for wear and tear regularly. Replace parts that show signs of damage. Ignoring small issues can lead to bigger problems later. Establish a consistent schedule for inspections. A proactive approach prevents costly repairs.

Invest time in training. Understanding how to operate and maintain the machine correctly is crucial. Sometimes, a small mistake can result in significant downtime. Workshops or training sessions help users avoid common pitfalls. It’s essential to stay informed about best practices.

Related Posts

-

Top 10 Uses for the Milling Machine X6325 in Modern Manufacturing Industries?

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

2025 Top Universal Milling Machine Features and Buying Guide

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

2026 How to Use Milling Machine X6325 Effectively?

-

Top Benefits of Using a Turret Milling Machine in Modern Manufacturing?