10 Essential Tips for Choosing the Right Milling Machine for Your Needs

In the ever-evolving landscape of manufacturing, choosing the right milling machine is paramount for enhancing productivity and maintaining precision. According to a recent report by MarketsandMarkets, the global milling machine market is projected to reach $5.74 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth is driven by the increasing demand for high-quality machined parts in industries ranging from aerospace to automotive. As the technology behind milling machines advances, the options available to manufacturers can feel overwhelming.

Industry expert Dr. John Snead, a leader in machining technology, states, “Selecting the right milling machine isn't just about specifications; it's about aligning the machine's capabilities with your specific production needs.” This sentiment highlights the importance of understanding the diverse range of features and functionalities that modern milling machines offer. Whether it's for precision engineering, rapid prototyping, or high-volume production, making an informed choice is essential to leverage the full potential of a milling machine, ensuring efficiency and cost-effectiveness in operations. With the right guidance and knowledge, manufacturers can navigate this crucial decision and invest wisely in the equipment that best suits their objectives.

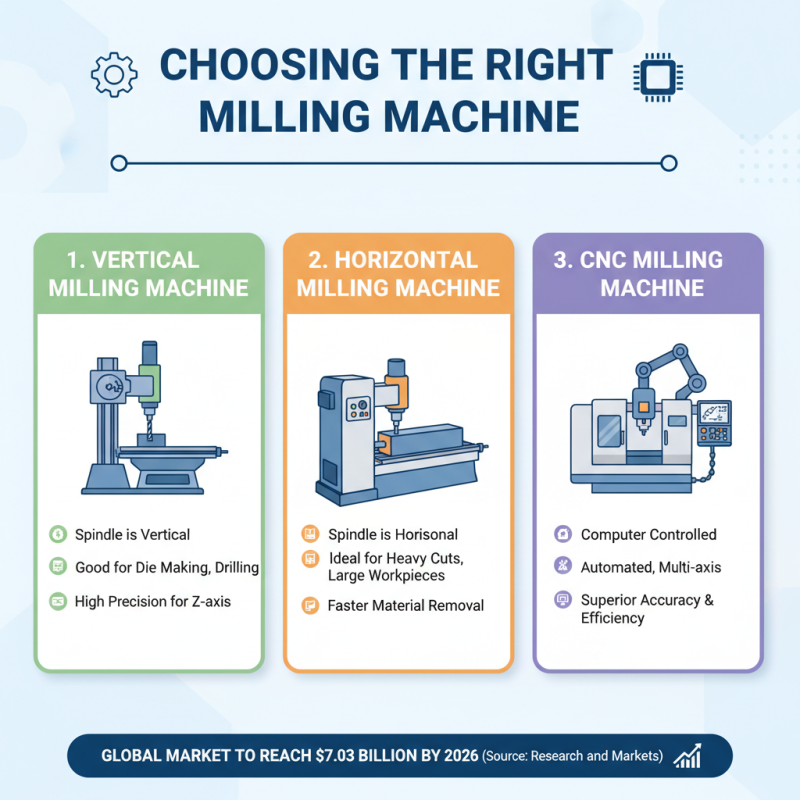

Understanding Different Types of Milling Machines Available in the Market

When it comes to selecting the right milling machine for your specific needs, it's crucial to understand the different types available in the market. Milling machines can generally be categorized into three main types: vertical, horizontal, and CNC (computer numerical control) milling machines. According to a recent market analysis by Research and Markets, the global milling machine market is expected to reach $7.03 billion by 2026, with CNC milling machines driving a significant portion of this growth due to their precision and efficiency.

Vertical milling machines are beneficial for jobs that require precision and versatility. They are ideal for small to medium-scale production tasks and can easily accommodate a variety of milling operations. On the other hand, horizontal milling machines are known for their ability to handle larger workpieces and heavier cutting operations, making them suitable for large-scale manufacturing. Meanwhile, CNC milling machines have revolutionized the industry by enabling complex designs and automation, which increases productivity. A report by Allied Market Research indicates that the CNC segment is projected to grow at a CAGR of 6.3% from 2021 to 2028, emphasizing their rising relevance in modern manufacturing.

Ultimately, understanding these types of milling machines, along with their specific strengths and applications, plays a pivotal role in selecting the best equipment tailored to your operational needs. As technology continues to evolve, it is vital for businesses to keep abreast of advancements in milling technology to maintain competitiveness in the market.

Key Features to Consider When Selecting a Milling Machine

When selecting the right milling machine, it's crucial to focus on key features that align with your specific operational needs. One of the primary considerations is the type of milling machine itself—vertical or horizontal. According to a report by Market Research Future, the global milling machine market is expected to grow at a CAGR of 6.4% from 2021 to 2028, indicating a rising demand for versatile and efficient milling technologies. Vertical milling machines are often preferred for their ease of use and versatility, while horizontal milling machines may be more suitable for larger, more complex projects.

Another vital feature to evaluate is the machine's speed and power specifications. Higher spindle speeds typically enhance material removal rates, which can significantly impact productivity. A 2021 study by Grand View Research emphasizes that a milling machine with variable speed capabilities allows operators to adapt to various materials and job requirements, improving efficiency. Additionally, it's essential to consider the machine's tooling compatibility and the availability of advanced features such as automated tool changers and CNC capabilities, which can dramatically increase precision and reduce cycle times, making operations more streamlined and cost-effective.

Assessing Your Budget: Cost Factors in Milling Machine Purchases

When considering the purchase of a milling machine, assessing your budget is crucial. The cost factors involved are not solely limited to the initial purchase price. It's essential to evaluate additional expenses such as maintenance, tooling, and operational costs. A machine that appears affordable at first glance may lead to higher long-term expenditures due to frequent repairs or the need for specialized accessories. Therefore, conducting thorough research and calculations will help you avoid unexpected financial burdens in the future.

Moreover, it's important to consider the type of milling machine that best suits your needs, as this can significantly affect your budget. Different machines come with varying features and capabilities, which can range from basic models to advanced CNC machines. While advanced options may require a larger upfront investment, they can provide better precision and efficiency, potentially offsetting their initial costs over time.

Carefully weighing these factors will enable you to make an informed decision, balancing your immediate financial limitations with your long-term production goals.

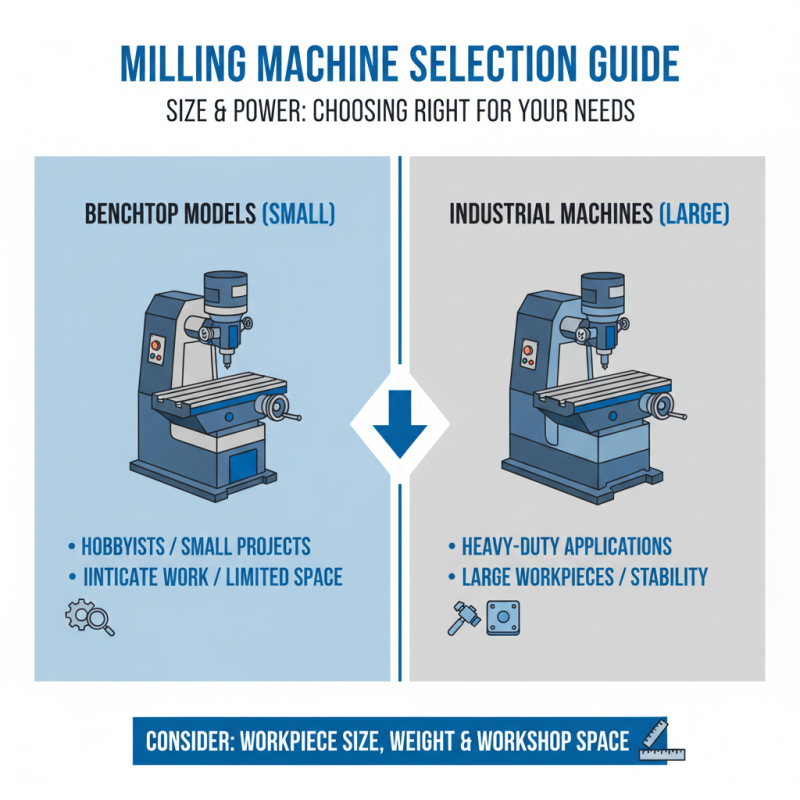

Determining the Right Size and Power for Your Milling Needs

When selecting a milling machine, understanding the right size and power for your specific needs is crucial. The size of the milling machine not only affects the type of projects you can undertake but also the space it will occupy in your workshop. Smaller, benchtop models are ideal for hobbyists or those working on intricate, smaller-scale projects, while larger, industrial machines cater to heavy-duty applications requiring ample workspace and stability. Consider the maximum workpiece dimensions and weight the machine can handle to ensure it aligns with your typical project requirements.

Power is another key factor in the milling machine selection process. Machines with higher horsepower can manage tougher materials and produce more significant results, beneficial for industrial work. However, it's essential to assess the types of materials you generally work with. For softer materials, a less powerful machine might suffice, offering efficiency without unnecessary energy consumption. Additionally, evaluate the variable speed options available, which can enhance versatility and precision in your milling tasks, allowing you to optimize performance based on the material and project complexity. Balancing these size and power considerations will guide you in choosing a milling machine that effectively meets your operational needs.

Evaluating Brand Reputation and Customer Support for Milling Machines

When selecting a milling machine, evaluating the brand reputation and customer support is crucial. A reputable brand often indicates a history of reliability and quality, which can significantly influence your long-term satisfaction with the machine. Researching customer reviews and testimonials can provide valuable insights into the experiences of others. Look for brands that consistently receive positive feedback regarding their machine performance and durability. A strong reputation can also translate into better resale value, should you decide to upgrade or change your equipment in the future.

In addition to brand reputation, robust customer support is a critical factor that should not be overlooked. Adequate customer service can make a substantial difference, especially if you encounter technical issues or require assistance during installation or operation. Evaluate the availability of support channels such as phone, email, or live chat, and consider the responsiveness of the customer service team. A brand that offers comprehensive technical support and readily accessible resources can save you considerable time and frustration. Ultimately, prioritizing these aspects will ensure you choose a milling machine that not only meets your operational needs but also provides peace of mind through dependable support.