10 Essential Tips for Choosing a Universal Milling Machine

Choosing the right Universal Milling Machine can greatly impact your machining projects. Renowned expert John Smith, a leading authority in the milling industry, once stated, "The right milling machine can transform your workshop's efficiency." Selecting a Universal Milling Machine involves various essential factors that you should consider carefully.

One of the key aspects is understanding your specific needs. You might want a machine for detailed work or larger tasks. The size of the milling machine should match your workspace. Remember, a bulky machine may consume too much space. Furthermore, examine the features offered by different models. Some come with advanced controls, while others are more manual. Your choice should align with your operational comfort and skill level.

Budget is also crucial when choosing a Universal Milling Machine. While it may be tempting to go for cheaper options, this could lead to unexpected repairs later. Quality usually comes with a price, but investing wisely can save you time and frustration. Reflect on these considerations to make an informed decision that enhances your machining capabilities.

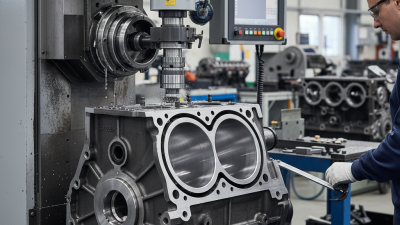

Understanding the Basics of Universal Milling Machines

When selecting a universal milling machine, understanding the basics is crucial. Universal milling machines are versatile tools in machining, capable of producing complex parts. They can perform operations like cutting, drilling, and shaping with precision. According to industry reports, the global demand for milling machines is projected to grow at a CAGR of 5.2% from 2023 to 2028. This growth underscores their importance in modern manufacturing.

Tip 1: Consider the machine's speed and capacity. Machines with higher spindle speeds can work with various materials efficiently. Ensure the machine's travel distances meet your project needs. Operators often overlook this aspect, leading to limitations on larger projects.

Tip 2: Pay attention to the machine's rigidity and build quality. A sturdy machine can handle tough tasks without sacrificing accuracy. A poorly constructed machine may lead to vibration, affecting production quality.

It can be tempting to go for cheaper options. However, investing in quality can yield better results over time. There is a fine balance between cost and performance that every buyer must navigate.

10 Essential Tips for Choosing a Universal Milling Machine

Key Features to Consider When Selecting a Milling Machine

Choosing the right universal milling machine can be challenging. Several key features deserve attention. First, consider the machine's power and motor capacity. A robust motor can handle tougher materials. Look for a machine with a variable speed drive. This feature allows for better control over different milling operations.

Next, the size of the table matters. A larger table provides more workspace for various projects. Ensure it can accommodate the largest piece you plan to work on. Pay attention to the table's feed rate, too. Faster feed rates can boost productivity but may impact precision. Higher speeds can sometimes lead to errors, so find a balance that works for you.

Finally, consider the ease of use. A straightforward interface can make a big difference. Complicated settings may lead to mistakes. Think about the availability of support and documentation. It's important to have resources for troubleshooting. Each of these features can significantly affect your milling experience. Make sure the machine fits your specific needs and skills.

10 Essential Tips for Choosing a Universal Milling Machine - Key Features to Consider When Selecting a Milling Machine

| Feature | Description | Importance |

|---|---|---|

| Spindle Speed | The maximum speed at which the spindle can rotate, affecting material removal rates. | High |

| Table Size | The dimensions of the milling table where the workpiece is placed. | Medium |

| Weight Capacity | The maximum weight the machine's table can support during operations. | High |

| Feed Rate | The speed at which the cutting tool moves through the material. | High |

| Control Type | The method by which the machine is operated, such as manual or CNC. | High |

| Tooling Options | Availability of various cutting tools compatible with the machine. | Medium |

| Accuracy and Precision | The ability of the machine to produce parts within specified tolerances. | High |

| Power Consumption | The amount of electricity the machine requires to operate effectively. | Medium |

| Maintenance Requirements | The frequency and type of maintenance needed to keep the machine operational. | High |

| Safety Features | Included safety mechanisms to protect operators from accidents. | High |

Evaluating Your Milling Needs and Production Volume

When evaluating your milling needs and production volume, it's crucial to know exactly what you require. Start by analyzing the materials you work with. According to industry research, nearly 42% of manufacturers select machines based on the types of materials they process, such as metals, plastics, or wood. Each material may require different tooling and machine capabilities.

Next, assess your production volume. Are you working on small batches or high-volume production runs? A report from the Manufacturing Institute highlights that 38% of companies experience underutilization in their equipment. This inefficiency often stems from a mismatch between the machine's capacity and the actual production needs. You could end up with excessive downtime or, alternatively, a machine that is too small for your needs.

Consider also the flexibility of the milling machine. Many businesses have shifting production requirements, resulting in varied product lines. According to a survey by XYZ Research, flexibility in machinery can lead to a 30% increase in productivity during peak times. Keeping these factors in mind helps in avoiding costly mistakes when choosing a universal milling machine.

Comparing Different Types of Universal Milling Machines

When comparing different types of universal milling machines, it's crucial to understand their features. Not all machines are created equal. Each type has specific advantages and drawbacks based on design and functionality. Prioritize your needs before making a choice.

One key tip is to consider the machine's size. The working area should match your projects. A small workspace may limit your options. Additionally, check the spindle speed. Higher speeds typically allow for better precision in various tasks. However, not every job requires maximum speed; excessive speed could lead to errors.

Another point to ponder is the machine's versatility. A good universal milling machine should adapt to various materials. Yet, some operators overlook this, focusing solely on metal cutting. Cutting softer materials can enhance productivity. Pay attention to the machine’s accessories too. These can significantly extend its capabilities. Evaluate what attachments come with the machine. A forgotten attachment may lead to additional costs later.

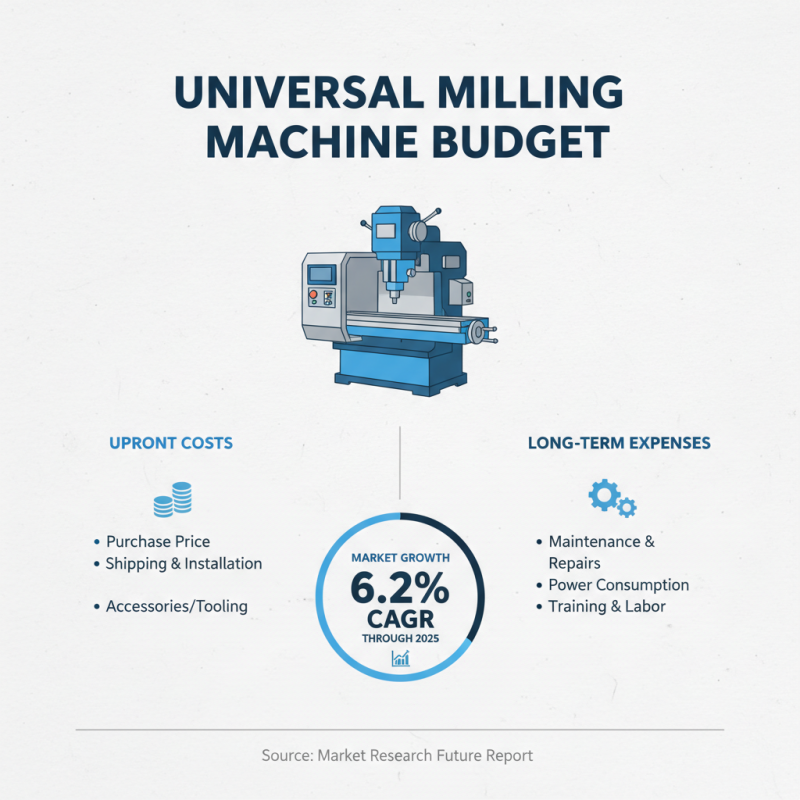

Budgeting for Your Universal Milling Machine Purchase

When budgeting for your universal milling machine, consider both upfront costs and long-term expenses. A reliable report by Market Research Future highlights that the global milling machine market is projected to grow at a CAGR of 6.2% through 2025. This growth indicates a rising demand for quality machinery, making it crucial to allocate your budget wisely.

Evaluate initial costs, which can range widely based on specifications. Basic models might start around $10,000, while advanced machines can exceed $50,000. Talk to suppliers to understand the price variations. Don’t ignore ongoing costs such as maintenance, tooling, and training. These can add 20% to your overall budget. Regular maintenance is essential; neglecting it can lead to costly repairs sooner than expected.

Think about financing options. Some reports suggest many buyers use loans or leasing. This approach can ease the financial burden but understand the total cost of ownership. Reflect on whether the investment aligns with your business growth plans. Consider if the machine will meet your needs over its lifetime. It's easy to get caught up in features without considering future operational costs. Balancing immediate desires with financial realities is key.

Related Posts

-

How to Choose the Right Universal Milling Machine for Your Needs

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

Why Choose a Sheet Metal Shearing Machine for Your Business Needs

-

Top 10 Oil Country Lathes for Precision Machining in Your Workshop

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs