2025 How to Use a Lathe: Essential Tips for Beginners and Pros

When it comes to machining and woodworking, mastering the use of a lathe is essential for both beginners and seasoned professionals. A lathe is a versatile tool that allows users to create intricate designs by rotating a workpiece against cutting tools. The foundational skills learned while operating a lathe not only enhance craftsmanship but also expand the possibilities of what can be achieved in various projects. Whether you're crafting delicate wooden spindles or shaping metal components, understanding the nuances of lathe operation is crucial for achieving high-quality results.

In this guide, we will delve into essential tips that cater to both beginners looking to familiarize themselves with the lathe and experienced operators aiming to refine their techniques. From setup and safety procedures to advanced techniques and troubleshooting, we will cover a range of topics that will empower you to leverage the full potential of your lathe. By developing a solid understanding of lathe mechanics and operations, you can elevate your projects and creativity to new heights. Embracing the art of lathe work opens up a world of opportunities in the realm of crafting and manufacturing, making it a worthy endeavor for anyone passionate about precision and design.

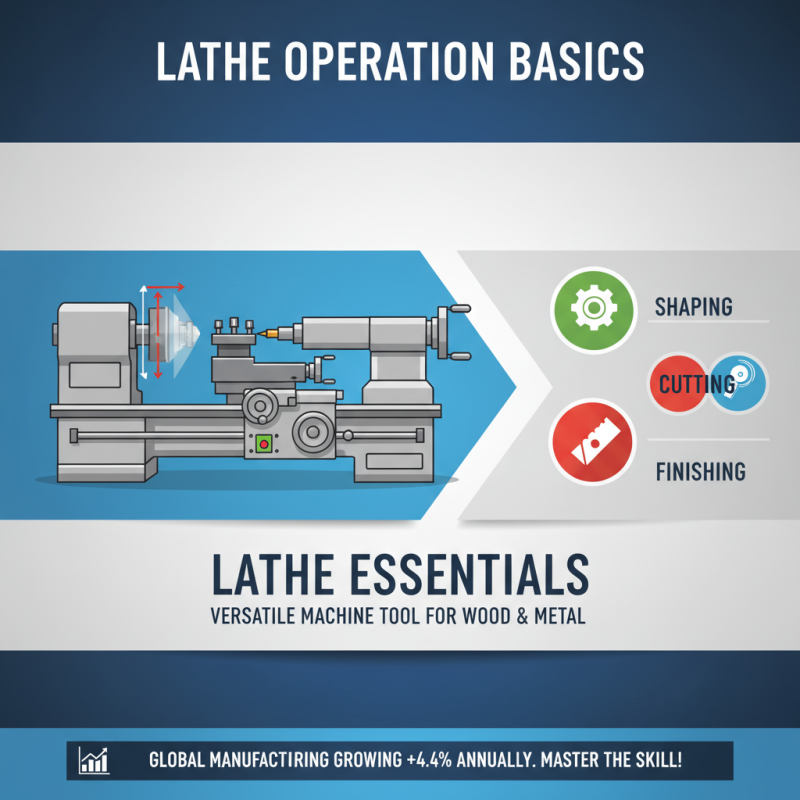

Understanding the Basics of Lathe Operation

Understanding the basics of lathe operation is crucial for both beginners and advanced users looking to enhance their skills. A lathe is a versatile machine tool used primarily for shaping, cutting, and finishing materials like wood and metal. According to a report by the Association for Manufacturing Technology (AMT), the global machine tool market is expected to grow by 4.4% annually, underscoring the importance of mastering lathe techniques as they remain integral to modern manufacturing processes.

In operating a lathe, it's essential to familiarize oneself with two main operations: turning and facing. Turning involves reducing the material's diameter, while facing deals with creating a flat surface at the end of a workpiece. Mastering these techniques allows for precise control over dimensions and improves the overall quality of the finished product. Moreover, a study conducted by the American Society of Mechanical Engineers (ASME) reveals that the proper setup and maintenance of lathes can increase production efficiency by up to 30%. This highlights the importance of understanding lathe operation fundamentals to not only boost productivity but also to ensure safety while working.

Furthermore, the correct use of cutting tools and understanding the various speeds and feeds of a lathe are critical. Data from the National Tooling and Machining Association indicates that nearly 20% of machining errors stem from incorrect tool settings and speeds. Therefore, beginners should take the time to learn these aspects thoroughly, as they are foundational for achieving optimal performance and consistent results on any lathe machine.

Essential Safety Precautions When Using a Lathe

When using a lathe, safety should always be the top priority, regardless of experience level. One of the fundamental precautions is to wear appropriate personal protective equipment (PPE). This includes safety glasses to protect your eyes from flying debris, ear protection to guard against excessive noise, and a dust mask to filter out any harmful particles generated during the machining process. Loose clothing or long hair should be secured to prevent entanglement in the moving parts of the lathe.

In addition to personal protection, it's crucial to familiarize yourself with the lathe's operation and maintenance guidelines. Ensuring that the machine is in good working condition before use can prevent accidents. Always check for any loose components or debris in the work area that could pose hazards. Keeping your workspace organized and clutter-free further enhances safety.

When setting up your workpiece, make sure it is securely clamped and properly balanced to avoid any unexpected movements during operation. By adhering to these essential safety precautions, both beginners and pros can create a secure environment conducive to effective woodworking and metalworking.

Step-by-Step Guide to Setting Up a Lathe for Various Projects

Setting up a lathe for various projects requires a clear understanding of your materials and objectives. Whether you are enhancing your skills as a beginner or honing your techniques as an experienced user, the setup phase can significantly affect the outcome of your work.

According to a report by the Precision Manufacturing Association, nearly 60% of lathe operators cite proper setup as a critical factor in achieving high-quality results. This is particularly vital in metalworking, where precision can mean the difference between success and costly errors.

To begin, ensure that your lathe is on a stable surface and aligned correctly. Use a level to check for any tilt, as this can lead to inaccuracies in cutting. It is advisable to familiarize yourself with the different components of the lathe, such as the tailstock, tool rest, and spindle. Each part plays a crucial role in ensuring that your projects are executed smoothly.

Tip: Regularly maintain your lathe by lubricating moving parts to reduce wear and enhance performance.

Next, consider the type of project you're working on and select the appropriate tools and speeds for your material. For instance, softer woods may require slower speeds to prevent splintering, while harder metals often need higher RPMs for efficient cutting.

According to research from the International Journal of Manufacturing Science, appropriate speed settings can increase the life of your tools by up to 30%.

Tip: Always have a plan in place, sketching out your project beforehand, which will better guide your setup and operational choices, ensuring that you stay on track throughout the process.

Common Lathe Techniques for Beginners and Advancing Skills

When it comes to mastering the lathe, both beginners and seasoned woodworkers can benefit from a solid understanding of common lathe techniques. For beginners, starting with basic operations such as turning, facing, and drilling is essential. These fundamental skills provide the foundation for more complex projects. Beginners should focus on mastering the proper grip of tools, maintaining proper speed settings, and learning how to read the workpiece correctly. Developing a keen sense of tool control and understanding the importance of safety measures will greatly enhance the turning experience.

As skills advance, lathe users can explore more intricate techniques like spindle turning and faceplate turning. Spindle turning involves shaping cylindrical objects and requires a steady hand and precise tool positioning. On the other hand, faceplate turning is ideal for creating larger, more complex shapes, such as bowls or hollow forms. At this stage, users should also delve into specialized cuts like the bead and cove cuts, which add depth and character to projects. Experimenting with different materials, adjusting tool angles, and refining finishing techniques will further elevate one's craftsmanship and confidence on the lathe.

Maintenance Tips for Longevity and Performance of Your Lathe

To ensure the longevity and optimal performance of your lathe, regular maintenance is paramount. Start by keeping the machine clean; dust and debris can accumulate in critical areas and impede the lathe's operation. Use a soft brush or compressed air to remove particles from the headstock, tailstock, and bed. After each use, a quick wipe down can prevent grime build-up and protect against rust.

Lubrication is another essential aspect of lathe maintenance. Regularly apply the appropriate lubricants to the moving parts, including the ways and lead screws, to reduce friction and wear. Pay attention to the manufacturer's guidelines regarding the type and frequency of oiling. Additionally, inspect and replace any worn or damaged parts, such as belts or bearings, to avoid further complications and ensure your lathe operates smoothly.

Lastly, check the alignment and calibration of your lathe periodically. An inaccurately aligned lathe can lead to poor machining results and unnecessary strain on the machine. Invest time in measuring and adjusting your lathe settings to enhance performance and accuracy. By following these maintenance tips, you'll not only extend the life of your lathe but also achieve consistently better results in your projects.

2025 How to Use a Lathe: Essential Tips for Beginners and Pros - Maintenance Tips for Longevity and Performance of Your Lathe

| Tip Category | Description | Frequency | Additional Notes |

|---|---|---|---|

| Cleaning | Remove chips and coolant regularly. | Daily | Use compressed air for hard-to-reach areas. |

| Lubrication | Apply lubricant to moving parts. | Weekly | Check manufacturer's recommendations for specific type. |

| Alignment | Check the alignment of the tailstock and headstock. | Monthly | Adjust as necessary to ensure precision. |

| Tool Inspection | Inspect and sharpen tools before use. | Before each use | Dull tools can affect the quality of work. |

| Safety Checks | Ensure safety equipment is in place and functional. | Before each use | Always wear safety goggles and hearing protection. |

Related Posts

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

2025 Top Universal Milling Machine Features and Buying Guide

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications