What is a Sheet Metal Shearing Machine and How Does It Work?

In the world of manufacturing, a Sheet Metal Shearing Machine stands out. This device shapes and cuts metal sheets with precision. Experts like John Smith, a prominent figure in metalworking technology, say, "Understanding the shearing process is key to optimizing production.” His insights highlight the importance of mastering this essential machinery.

The function of a Sheet Metal Shearing Machine is straightforward yet vital. It employs sharp blades to slice through metal, generating clean edges. However, many operators overlook maintenance. Neglect can lead to inaccuracies, affecting the final product quality. It’s crucial to regularly inspect these machines to maintain efficiency.

Moreover, not all operators grasp the intricacies of different shearing techniques. A simple mistake can result in waste or unsafe conditions. Awareness of these potential pitfalls can enhance both safety and productivity. Embracing knowledge about the Sheet Metal Shearing Machine can significantly improve outcomes in metal fabrication industries.

Definition of a Sheet Metal Shearing Machine

A sheet metal shearing machine is a vital tool in metal fabrication. It cuts metal sheets into desired shapes and sizes. The machine uses a powerful blade that moves down to shear the material. This process is crucial in various industries, including automotive and aerospace.

According to industry reports, the global sheet metal fabrication market is expected to reach $200 billion by 2026. This reflects a growing need for precise and efficient cutting tools. However, the shearing process can produce rough edges. Operators must consider additional finishing steps to ensure quality. Rough edges may lead to weaknesses in the final product.

Many shearing machines come with features to enhance accuracy. But, not all machines are suitable for every application. Choosing the wrong type may result in wasted materials and increased costs. Thus, attention to detail in selecting equipment is crucial for success. Keeping up with technological advancements can mitigate these challenges. Operators should constantly seek improvement and training for optimal performance.

Key Components of a Shearing Machine

A shearing machine is essential in sheet metal processing. Its key components determine how effectively it works. The machine generally consists of a frame, blade, and a drive system. Each part plays a critical role in the shearing process.

The frame provides stability and support. It must withstand the forces exerted during operation. A strong frame prevents vibrations, ensuring smooth cuts. The blades are made from hardened steel. They need to be sharp for accurate cuts. A dull blade can lead to uneven edges, causing waste. Regular maintenance of the blades is crucial but often overlooked.

The drive system controls the movement of the blades. Electric motors are common, but hydraulic systems are also used. They offer precise control. Users sometimes struggle with adjusting these systems. Getting the settings right can be challenging but essential for clean cuts. Even experienced operators make mistakes. Regular training can help reduce errors and improve efficiency.

What is a Sheet Metal Shearing Machine and How Does It Work? - Key Components of a Shearing Machine

| Component | Description | Function |

|---|---|---|

| Shear Blade | A hardened steel blade that performs the cutting action. | Cuts the sheet metal by means of a shearing process. |

| Table | A flat surface that supports the metal sheet during cutting. | Provides stability and accuracy to the cutting operation. |

| Back Gauge | An adjustable stop that determines the position of the metal sheet. | Ensures consistent cutting lengths across multiple pieces. |

| Hydraulic System | A system that uses hydraulic fluid to generate force. | Provides the necessary cutting force for the shear blade. |

| Control Panel | Interface for operating the shearing machine. | Allows the operator to set parameters and control the machine. |

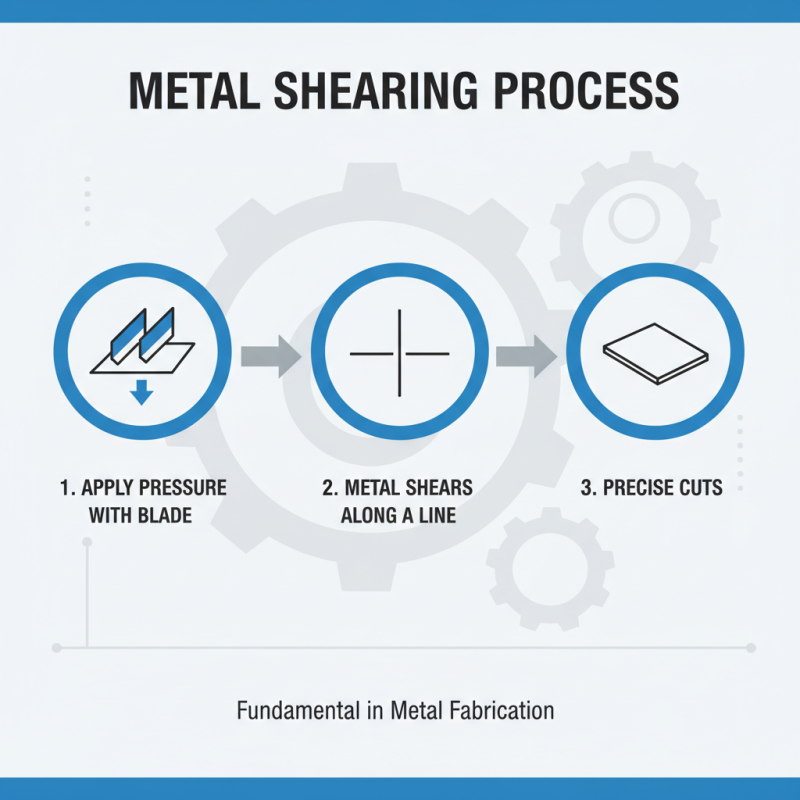

Understanding the Shearing Process: How It Works

The shearing process is fundamental in metal fabrication. It involves cutting sheet metal into specific shapes and sizes. A sheet metal shearing machine uses a sharp blade to apply pressure. This pressure forces the metal sheets to shear along a straight line. The result? Precise cuts without any extra mechanical manipulation.

When the machine is activated, a hydraulic or mechanical system moves the blade. This is where some imperfections may occur. Not every cut is perfect. Minor discrepancies can arise due to misalignment or variations in material thickness. It’s crucial to monitor the settings closely. If the blade isn’t sharp enough, the quality of the cut diminishes.

Proper maintenance is necessary to ensure efficiency. Regularly checking for wear can help maintain accuracy. Operators may overlook these details, leading to poor outcomes. They should be vigilant about potential issues. A moment’s inattention can cost time and resources. The shearing process, while effective, requires constant attention to detail.

Types of Shearing Techniques Used in Metalworking

In the metalworking industry, shearing techniques are crucial. They enable precise cuts without affecting the material's integrity. One common method used is mechanical shearing, where a blade moves against a stationary surface. The force applied cuts through the sheet metal effectively. This technique is favored for its speed, making it ideal for high-volume production.

Another technique is hydraulic shearing. This method uses hydraulic pressure to achieve cuts. It allows for greater control over the cutting process, especially with thicker metals. Reports indicate that up to 70% of metal fabrication relies on shearing processes. However, this technique can lead to more material wastage if not monitored closely.

Laser shearing is gaining traction as well. It offers higher precision and reduces burrs on the edges. However, it requires a significant investment in technology. As industries shift towards automation, workers must adapt. Training in new shearing technologies has become essential. By embracing these changes, companies can enhance their efficiency, but lingering issues around skill gaps remain a challenge.

Metal Shearing Techniques Used in Metalworking

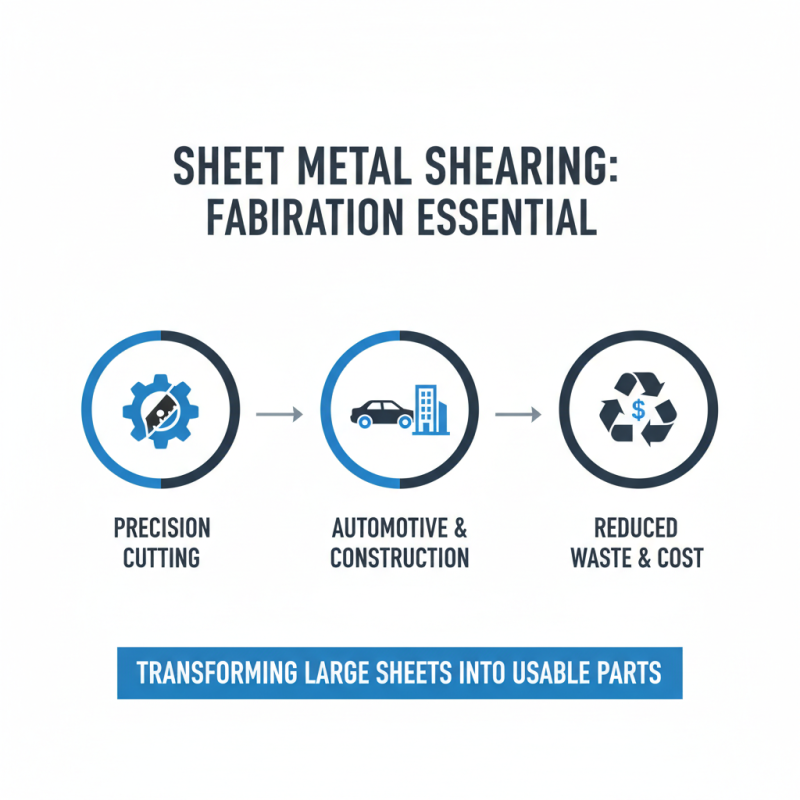

Applications and Benefits of Sheet Metal Shearing Machines

Sheet metal shearing machines are vital tools in metal fabrication. They excel at cutting large sheets into smaller, manageable sections. This process is essential in various industries, from automotive to construction. The precision offered by these machines ensures that metal pieces fit together seamlessly. This reduces waste, a key factor in any production process.

The applications of sheet metal shearing machines are vast. In automotive manufacturing, they help create parts essential for vehicle assembly. In construction, they provide essential elements for frameworks and structures. The benefits are clear: increased efficiency, accuracy, and reduced labor costs. However, not every operation maximizes the potential of these machines. Some workshops may suffer from poor operator training or inefficient maintenance practices.

The flexibility of these machines allows for customization. Each project may require different specifications, dictating the need for adjustments. While sheet metal shearing machines boast great capabilities, operators must continually seek improvement. Identifying inefficiencies can lead to better performance and reduced costs. It's a reflection of the ongoing journey in honing skills and processes. Each cut could be better, each setup a chance to learn more.

Related Posts

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs

-

2026 Best Valve Seat Boring Machine Options to Consider?

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry

-

2025 How to Use a Lathe: Essential Tips for Beginners and Pros