Why Choose a Sheet Metal Shearing Machine for Your Business Needs

When considering equipment for your fabrication shop, a Sheet Metal Shearing Machine stands out. This tool provides precision cutting for various metal types. It is essential for businesses that demand accuracy and efficiency. With its sharp blades and reliable operation, it minimizes waste and maximizes productivity.

Investing in a Sheet Metal Shearing Machine can be a game-changer. It allows for quick adjustments and a range of thicknesses for different materials. This versatility enables businesses to adapt and meet customer needs more effectively. However, choosing the right machine requires careful planning and reflection. Different models offer unique features that may or may not suit your workflow.

Remember, while a Sheet Metal Shearing Machine can enhance productivity, it's not a one-size-fits-all solution. Some machines may present challenges regarding maintenance. It's crucial to consider your specific requirements before making a purchase. Ultimately, the right choice can boost your business’s capabilities significantly.

Understanding Sheet Metal Shearing Machines and Their Functionality

Sheet metal shearing machines are vital in various industries. They perform precise cutting, shaping, and shearing tasks. These machines streamline production processes. They can handle different types of metals, like aluminum and stainless steel. The adaptability makes them popular in manufacturing.

Understanding how these machines work is essential for any business. A shearing machine typically uses a sharp blade to cut through metal sheets. The operation is simple yet effective. However, operators must be trained to handle them safely. Misuse could lead to accidents or material waste. This is a challenge many companies face.

Efficiency is another aspect to consider. These machines, if maintained poorly, can slow down production. Regular checks and adjustments are necessary. Investing in proper machinery is important, but so is maintenance. Some may overlook this, leading to frustrating delays. Rethinking current processes can yield better outcomes in the long run.

Benefits of Using Shearing Machines in Manufacturing Processes

Shearing machines are vital in modern manufacturing. They streamline metal processing, resulting in greater efficiency. According to a report by MarketsandMarkets, the metal shearing market is projected to grow at a compound annual growth rate of 4.5% from 2022 to 2027. This growth reflects the increasing demand for precision in manufacturing.

Using a shearing machine reduces the chances of material wastage. The right machine settings can optimize the cutting process. Studies show that proper shearing can boost production rates by as much as 30%. This efficiency is crucial for staying competitive in the metal fabrication industry.

However, not every company implements these machines effectively. Some may overlook regular maintenance, leading to unexpected downtime. Operators may need more training too. Recognizing these areas for improvement is essential. Sorry to say, without good training and maintenance, even the best machines can fail to meet expectations. Balancing efficiency and training is key in maximizing the benefits of shearing machines.

Why Choose a Sheet Metal Shearing Machine for Your Business Needs - Benefits of Using Shearing Machines in Manufacturing Processes

| Feature | Description | Benefits |

|---|---|---|

| Precision Cutting | Provides accurate cuts with minimal tolerance. | Reduces waste and improves product quality. |

| Speed | Able to process large volumes in a short period. | Increases production efficiency and throughput. |

| Versatility | Can cut various materials and thicknesses. | Suitable for different manufacturing needs. |

| Operator Safety | Designed with safety features to protect operators. | Minimizes workplace accidents and injuries. |

| Cost-Effectiveness | Reduces the overall cost of material processing. | Improves profit margins and competitive pricing. |

Key Features to Consider When Choosing a Shearing Machine

When selecting a sheet metal shearing machine, consider its capacity and blade configuration. The maximum sheet size and thickness are crucial. Machines vary in their ability to handle heavy or thin sheets. This affects your project's scope and efficiency. Think about the volume of work you expect.

Tips: Assess your daily output needs. This will help identify the right blade length for your workflow. Consider if you might need a larger machine in the future.

Next, think about the machine's ease of use. User-friendly controls save time and reduce errors. The design should allow quick adjustments. Check if the machine offers features such as auto-lubrication. This can minimize maintenance efforts, but it could also lead to overlooking necessary manual checks.

Remember, safety features matter. Look for machines with emergency stops and protective shields. Safety warnings should be clear and accessible. However, do not rely solely on these. Regular training for operators reduces risks and ensures everyone understands the machine’s capabilities and limits.

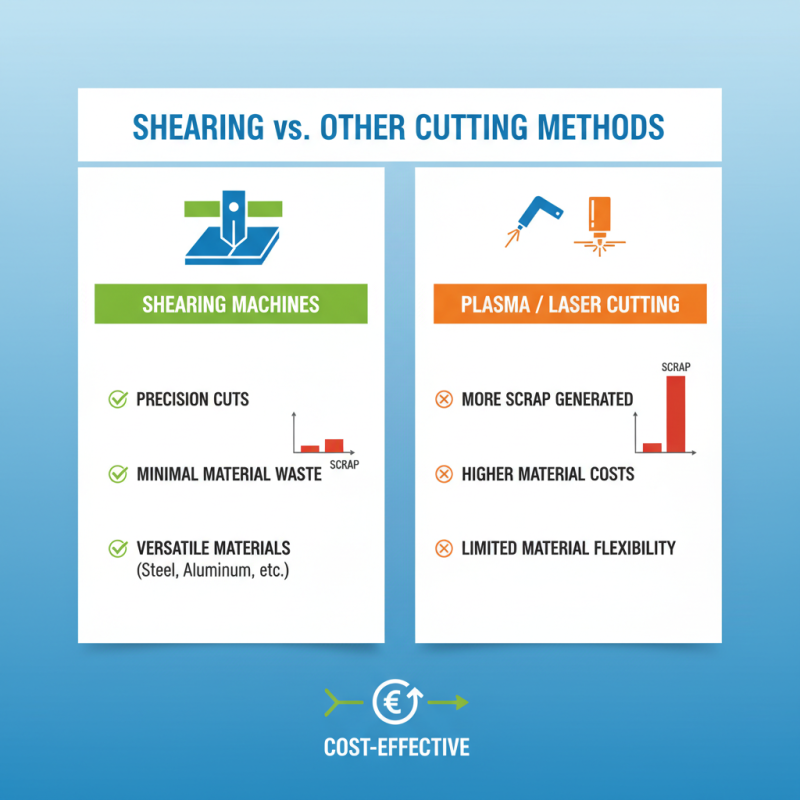

Comparative Analysis: Shearing Machines vs. Other Cutting Methods

When evaluating different cutting methods, shearing machines stand out for several reasons. A recent industry report shows that shearing can achieve precision cuts with minimal material waste. In contrast, methods like plasma or laser cutting typically generate more scrap, increasing costs. Shearing machines are effective for working with various materials, including steel and aluminum, offering flexibility that other methods often lack.

Tips: Always consider the thickness of the material before choosing a method. Shearing machines excel on thicker sheets while other methods may struggle. Regular maintenance increases efficiency and extends the lifespan of the machine.

Shearing machines are slower than some other methods like waterjet cutting. If your project demands speed, this might present a challenge. However, they require less energy, making them more cost-effective in the long run. A study indicated that energy costs associated with shearing can be up to 30% lower than laser cutting over time.

Tips: Evaluate your business needs. If high-volume production is important, shearing may be the right choice. On the other hand, if detail work is crucial, consider complementing your setup with additional cutting technologies. Balancing speed and precision is key to maximizing productivity.

Cost-Effectiveness and Efficiency of Shearing Machines in Business

The cost-effectiveness of sheet metal shearing machines is striking. According to industry reports, businesses can reduce material waste by up to 30% with these machines. This efficiency translates directly into lower operational costs. The initial investment in a shearing machine can be recouped within a year, especially for high-volume projects.

On the efficiency front, modern shearing machines can cut materials up to 10 times faster than manual methods. For example, a typical machine can process sheets at speeds exceeding 30 meters per minute. Yet, operators must be trained properly to avoid mistakes. Misalignment or incorrect settings can lead to wasted materials, undermining potential savings.

In many cases, manual labor is not only slower but also less accurate. The precision of shearing machines minimizes errors. Industry studies reveal that automated processes in metalwork significantly enhance product quality. However, it’s essential to regularly maintain these machines. Neglect can slow down production unexpectedly or lead to costly repairs.

Related Posts

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

Top Features of Drilling Machines You Need to Know Before Buying

-

2025 How to Use a Lathe: Essential Tips for Beginners and Pros

-

Top 10 Oil Country Lathes for Precision Machining in Your Workshop

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine