Top 10 Tips for Using an Oil Country Lathe Effectively?

The Oil Country Lathe plays a crucial role in the oil and gas industry. Expert John Smith emphasizes, “Understanding your lathe is key to efficiency.” This equipment is vital for machining large oilfield components. However, many users struggle with maximizing its potential.

Running an Oil Country Lathe requires precision and knowledge. Mistakes can lead to wasted materials and time. Beginners often overlook important details, like tool selection and machine settings. A small error can escalate into significant issues. It's not just about having the best machine, but knowing how to use it effectively.

Operators must continuously learn and adapt. Each job may demand different techniques. Reflecting on past experiences can help avoid future mistakes. Awareness of common pitfalls is essential. These insights can lead to smoother operations and better outputs when using an Oil Country Lathe.

Understanding the Basics of Oil Country Lathes

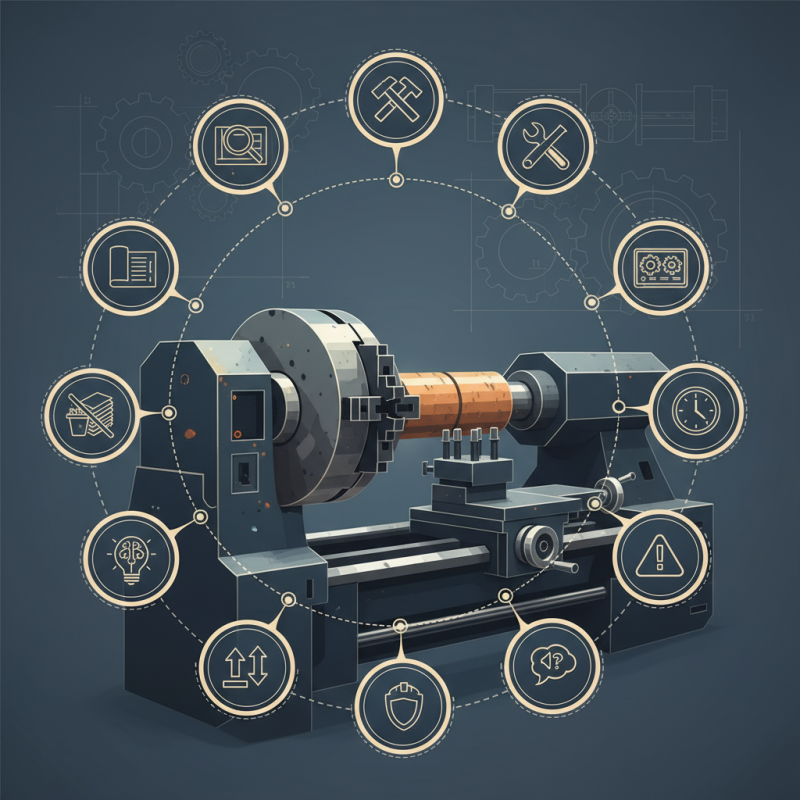

Oil country lathes are essential tools in the oil and gas industry. They are designed to handle large diameter pipes and other heavy materials. Understanding their basics can significantly enhance their effectiveness. These machines typically feature a large spindle and a robust support structure, allowing them to manage the weight and stress of heavy workpieces. Operators need to familiarize themselves with these components to maximize efficiency.

Proper setup is crucial when using an oil country lathe. The workpiece must be securely mounted to prevent vibrations. Vibration can lead to inaccuracies and wasted materials. Additionally, selecting the right cutting tools is vital. Incorrect tools can cause damage and require adjustments. It’s also important to regularly check the tool condition. Dull tools can compromise precision and increase production time.

Operators may find themselves frustrated at times. It can take practice to master all controls and adjustments. Mistakes often occur during the initial setup or cutting process. Recognizing these challenges is key to improvement. Reflecting on past experiences helps to build better techniques and routines in the long run.

Top 10 Tips for Using an Oil Country Lathe Effectively

| Tip Number | Tip Description | Application |

|---|---|---|

| 1 | Familiarize Yourself with Machine Controls | Understanding all functions ensures safe operation. |

| 2 | Select the Right Cutting Tool | Utilizing the right tool improves efficiency and tool life. |

| 3 | Maintain Proper Lubrication | Reduces wear and ensures smooth operation. |

| 4 | Regularly Inspect for Wear and Damage | Prevents malfunction and ensures accuracy. |

| 5 | Set the Correct Speed and Feed Rates | Optimizes cutting performance and tool life. |

| 6 | Use Proper Workholding Techniques | Ensures part stability during machining. |

| 7 | Implement a Maintenance Schedule | Extends machine life and reliability. |

| 8 | Monitor Temperature During Operation | Prevents overheating and damage. |

| 9 | Train Operators Regularly | Ensures safety and effective use of the lathe. |

| 10 | Understand Material Properties | Appropriate techniques reduce waste and errors. |

Essential Safety Precautions for Operating a Lathe

When operating an oil country lathe, safety should be at the forefront. According to the National Institute for Occupational Safety and Health, over 400 fatalities occur annually in machine-related incidents. Such statistics highlight the need for strict adherence to safety protocols.

Before starting any lathe operation, ensure your work area is clean. A cluttered workspace can lead to accidents. Always wear personal protective equipment, including eye protection and gloves. This reduces the risk of injury from flying debris. Be aware of the lathe’s emergency stop mechanism; knowing how to stop the machine quickly can save lives.

While working, keep your hands away from the rotating parts. Many operators have experienced near misses due to unintentional contact. Modify your approach; use tools to assist rather than direct hand contact. It's crucial to maintain a firm stance. A slip can lead to severe consequences.

Always double-check the workpiece is secured before starting the lathe. Loose materials can come loose and cause dangerous projectiles. Following advanced safety measures is vital to create a secure working environment. In industry, about 30% of all accidents result from inadequate safety practices. Reflecting on this can lead to improved operational protocols.

Top 10 Tips for Using an Oil Country Lathe Effectively

Key Maintenance Practices for Longevity of Equipment

Maintaining an oil country lathe is crucial for its longevity and performance. Regular maintenance practices can significantly enhance efficiency and reduce operational costs. According to a report from the Machinery Maintenance Institute, timely maintenance can extend equipment life by up to 30%. This highlights the importance of developing a routine care plan.

Cleaning and lubricating the lathe are essential steps. Dust and debris can cause friction and wear. Using high-quality lubricants and regularly checking oil levels will ensure smooth operation. A study from the Mechanical Engineering Group indicates that proper lubrication can improve machine efficiency by as much as 15%. Visual checks for dirt buildup should occur weekly.

Another vital maintenance practice is to conduct regular inspections for wear and tear. This includes checking the spindle bearings and drive belts. Many operators underestimate the impact of small issues. Ignoring these can lead to larger problems down the line. With appropriate monitoring, you can catch issues early. Creating a checklist may help in identifying potential faults more systematically. Such practices can prevent costly downtime and maintain production flow.

Techniques for Achieving Precise Machining Results

Precision machining is crucial in oil country lathes. Achieving accurate results is often challenging. Various techniques can enhance your machining process. First, focus on tool alignment. Misalignment can lead to significant errors. A study showed that a mere 0.1 mm deviation can result in a 25% increase in scrap. Regular checks are necessary for optimal performance.

Another key aspect is tool selection. The right tool can vastly improve finish quality. A recent industry report indicated that using carbide tools can enhance tool life by up to 30%. However, proper selection often requires experience and insight. Many overlook the importance of monitoring wear patterns. Wear affects precision, leading to unexpected downtime.

Maintaining optimal cutting speeds is essential. Speeds must align with material properties. A mismatch can result in poor results. Moreover, operators should embrace continuous learning. Mistakes happen, and reflecting on them is key to improvement. Only through trial and error can one master the complex behaviors of different materials and tools. The journey of precision is ongoing, and there's always room for growth.

Tips for Optimizing Workflow and Productivity in the Workshop

In any workshop, optimizing workflow is crucial. A well-organized space leads to greater efficiency. Start by decluttering the area around the oil country lathe. Keep essential tools within arm’s reach. This simple change can save valuable time.

Another effective strategy is to develop a routine. Designate specific tasks for each session. Consistency is key. When you have a clear plan, you reduce the chances of making mistakes. Yet, be open to adjusting this routine. Sometimes, an unexpected challenge arises, forcing you to rethink your approach.

Regular maintenance is also important. Inspect the lathe for any wear or damage. Identifying issues early can prevent costly repairs later. However, it’s easy to overlook this step when busy. That’s where reflection comes in. Take a moment to evaluate your daily habits. Are they supporting your productivity, or are there areas to improve? Each small change can lead to significant results in the long run.

Related Posts

-

Top 10 Oil Country Lathes for Precision Machining in Your Workshop

-

2025 Top Universal Milling Machine Features and Buying Guide

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

Why Choose a Sheet Metal Shearing Machine for Your Business Needs

-

Top Features of Drilling Machines You Need to Know Before Buying

-

2026 How to Use Milling Machine X6325 Effectively?