Top Features of Drilling Machines You Need to Know Before Buying

In the competitive landscape of construction and manufacturing, the drilling machine stands out as a crucial tool, paramount for precision and efficiency. According to a recent report by the Global Industry Analysts, the drilling machine market is projected to reach USD 8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.3%. This surge highlights the increasing demand for high-quality, durable drilling machines that can deliver exceptional performance across various applications.

Industry expert, Dr. Samuel Wright, a renowned authority in drilling technologies, emphasizes the importance of making an informed decision when purchasing these machines. He states, "Understanding the features of drilling machines is not just beneficial—it's essential for maximizing productivity and ensuring safety on the job site." As potential buyers, it becomes imperative to understand the top features that define the effectiveness and reliability of a drilling machine, ranging from motor power to torque options and beyond. With this knowledge, you can ensure that your investment meets the specific demands of your projects.

Key Types of Drilling Machines on the Market Today

When considering the purchase of a drilling machine, it's crucial to be aware of the key types available on the market today. There are several categories, each tailored for specific tasks and environments. For instance, portable drilling machines are favored for their versatility and ease of use. They are ideal for light to moderate tasks, allowing users to maneuver them easily in various locations. Their compact design makes them suitable for home projects and smaller jobs, such as drilling into wood or soft metals.

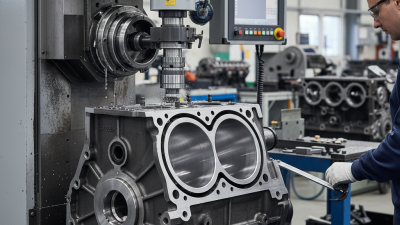

On the other hand, industrial drilling machines are designed for heavy-duty operations, offering greater power and durability. These models are equipped with advanced features to handle tougher materials and larger projects, making them essential in manufacturing and construction settings. Another noteworthy type is the drill press, which provides precision and stability, suitable for repetitive drilling tasks. With varying spindle speeds and the ability to adjust depths, drill presses are perfect for intricate work that demands accuracy. Understanding these types will help you make an informed decision when selecting a drilling machine that suits your needs.

Top Features of Drilling Machines You Need to Know Before Buying - Key Types of Drilling Machines on the Market Today

| Drilling Machine Type | Key Features | Applications | Power Source |

|---|---|---|---|

| Electric Drill | Portable, Lightweight, Variable Speed | Home Improvement, DIY Projects | Electric |

| Hammer Drill | Impact Function, High Power | Masonry, Concrete Drilling | Electric |

| Cordless Drill | Battery Operated, High Mobility | Various Drilling Tasks | Battery |

| Benchtop Drill Press | Stationary, Precision Control | Woodworking, Metalworking | Electric |

| Magnetic Drill | Strong Magnet Base, Heavy-duty | Steel Fabrication, Industrial Uses | Electric |

Essential Specifications to Consider When Choosing a Drilling Machine

When selecting a drilling machine, understanding the essential specifications is crucial to ensure it meets your operational needs. One of the primary specifications to consider is the motor power, typically measured in watts or horsepower. Drilling machines with a higher motor power, typically over 750 watts, deliver more torque, allowing for efficient drilling in tougher materials. According to industry reports, machines with at least 1 HP are recommended for professional applications and can dramatically increase productivity by reducing drilling time and facilitating cleaner holes.

Additionally, the drilling capacity—often specified in terms of maximum drilling diameter—is an important factor to consider. Machines may offer varying drilling capacities based on material types; for example, a machine may effectively drill 13 mm in steel while being capable of drilling much larger holes in softer materials like wood. Industry data shows that a drilling machine capable of a diameter of at least 16 mm in metal is better suited for workshop applications that require versatility and efficiency. Lastly, attention should also be paid to the weight and build of the machine, as systems weighing over 20 kg provide stability while drilling, thereby minimizing vibration and enhancing accuracy.

Top Features of Drilling Machines

Safety Features to Look for in Drilling Equipment

When selecting drilling equipment, safety should be a top priority. According to the U.S. Bureau of Labor Statistics, nearly 74,000 injuries occur each year in the construction industry, many of which are associated with drilling operations. Therefore, understanding the essential safety features of drilling machines is crucial for both operator protection and overall workplace safety.

One vital safety feature to consider is the presence of automatic shut-off mechanisms. These systems are designed to deactivate the drill in case of an emergency, helping to prevent serious injuries. A recent industry report indicated that equipment with these shut-off features can reduce injury incidents by approximately 30%. Additionally, machines equipped with protective enclosures can significantly minimize the risk of users coming into contact with moving parts, thus enhancing the overall safety of the operation.

Another important aspect is ergonomics. Ergonomically designed drills can decrease the risk of musculoskeletal injuries, which are common among operators who perform repetitive motions. A study by the National Institute for Occupational Safety and Health revealed that ergonomic interventions can decrease hand-arm vibration syndrome occurrences by up to 50%. By prioritizing drills that incorporate safety features such as automatic shut-offs and ergonomic designs, operators can ensure a safer work environment and comply with safety regulations more effectively.

Technological Advancements Impacting Modern Drilling Machines

The technological advancements in drilling machines have significantly transformed the landscape of the drilling industry. Enhanced automation through advanced control systems allows for precise operation, reducing human error and increasing efficiency. These modern machines are equipped with sensors and smart technology that provide real-time data monitoring, making it easier for operators to manage drilling parameters effectively and optimize performance.

Moreover, the integration of cutting-edge materials and engineering designs has resulted in drilling machines that are not only more durable but also capable of handling a wider range of geological conditions. Innovations such as improved drill bit technology, which utilizes advanced coatings and geometries, have led to faster penetration rates and longer tool life. Additionally, eco-friendly technologies are now being implemented, minimizing the environmental impact during drilling activities. These advancements are essential for ensuring sustainability while meeting the increasing demand for resource extraction in a responsible manner.

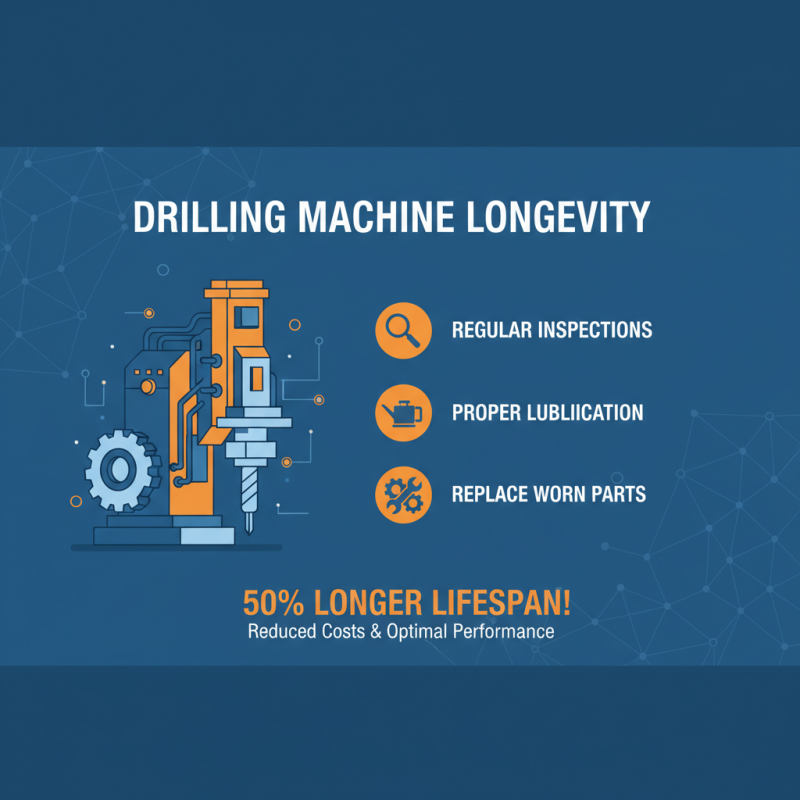

Maintenance Tips for Extending the Life of Your Drilling Machine

Maintaining the longevity of your drilling machine is essential for ensuring optimal performance and reducing overall costs. According to industry reports, proper maintenance can extend the lifespan of drilling machines by more than 50%. To achieve this, regular inspections and timely servicing are crucial. Key maintenance practices include checking the alignment and tightness of all fittings, ensuring that the lubrication systems are functioning correctly, and replacing any worn parts before they lead to major failures.

Moreover, keeping the machine clean is often overlooked. Dust and debris can interfere with moving parts and contribute to wear and tear. Using compressors to blow out dirt and utilizing appropriate cleaning solvents for oil and grease buildup can significantly enhance the machine's efficiency. Additionally, maintaining optimal operating conditions, such as temperature and humidity, is vital. A study indicated that machines operated in controlled environments have a failure rate 30% lower than those exposed to extreme conditions. Therefore, adopting a comprehensive maintenance routine not only improves the operational lifespan of your drilling machine but also leads to sustained productivity and reduced downtime.

Related Posts

-

2025 How to Use a Lathe: Essential Tips for Beginners and Pros

-

Top 10 Oil Country Lathes for Precision Machining in Your Workshop

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

How to Choose the Right Universal Milling Machine for Your Needs

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs