Top 10 Oil Country Lathes for Precision Machining in Your Workshop

The demand for precision machining in various industries has led to a significant rise in the usage of specialized machinery, particularly the Oil Country Lathe. As a vital tool for shaping and machining large, heavy workpieces typically used in the oil and gas industry, these lathes are engineered to provide outstanding accuracy and durability. According to a recent report from the International Association of Machining Professionals, the global market for oil country lathes is projected to grow at a compound annual growth rate (CAGR) of 5.2% over the next five years, reflecting the ongoing evolution in machining technology.

Industry experts emphasize the importance of selecting the right Oil Country Lathe for workshop applications. John Smith, a leading specialist in precision machinery, states, "Investing in a high-quality Oil Country Lathe is crucial for any workshop aiming to achieve exceptional precision and efficiency." With various models available, each designed to meet specific machining needs, understanding their features and capabilities is essential for maximizing productivity and ensuring accuracy in operations. This article will explore the top 10 oil country lathes that can significantly enhance your workshop's machining capabilities.

Benefits of Using Oil Country Lathes in Precision Machining

Oil country lathes are essential tools in precision machining, particularly when working with large bore components and heavy materials. One of the primary benefits of these lathes is their capability to handle long and heavy workpieces with remarkable accuracy. This is largely due to their robust construction, which minimizes vibrations during machining processes, ensuring a smooth and stable operation. The design also allows for greater flexibility in production, enabling users to manage various tasks from turning to drilling, enhancing overall efficiency in the workshop.

Another significant advantage of using oil country lathes is their ability to produce high-quality finishes and tight tolerances. The precision engineering behind these machines ensures that even complex geometries can be achieved with ease. Additionally, oil country lathes often incorporate advanced features such as programmable controls and automated feeding systems, which reduce human error and boost productivity. This combination of strength and precision makes oil country lathes an invaluable asset for any workshop focused on high-precision machining tasks.

Top 10 Oil Country Lathes for Precision Machining

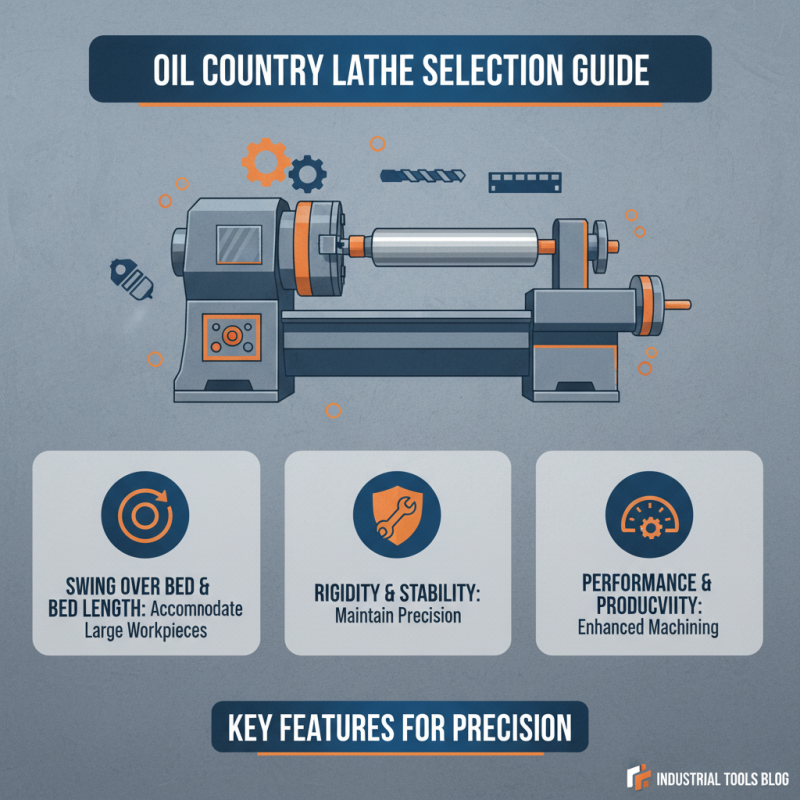

Key Features to Look for in an Oil Country Lathe

When selecting an oil country lathe for precision machining, it's essential to consider several key features that enhance performance and productivity. First and foremost, the machine's swing over bed and length of bed play a crucial role in determining the size of the workpieces it can accommodate. A larger swing allows for the machining of bigger diameter materials, while an extended bed length facilitates longer parts, thereby increasing versatility in a workshop setting. Additionally, the rigidity and stability of the lathe's construction are fundamental in maintaining precision during cutting operations, especially when dealing with heavy or large components.

Another vital aspect is the lathe's spindle speed and torque. A lathe equipped with variable speed options provides adaptability for machining various materials and designs, allowing for more efficient processing. High torque at low speeds is particularly beneficial when working with tougher alloys, ensuring that the cutting tools remain effective without compromising the quality of the finish. Furthermore, advanced features such as programmable controls and automatic tool changers can significantly enhance operational efficiency, reducing setup times and improving overall productivity in a professional machining environment.

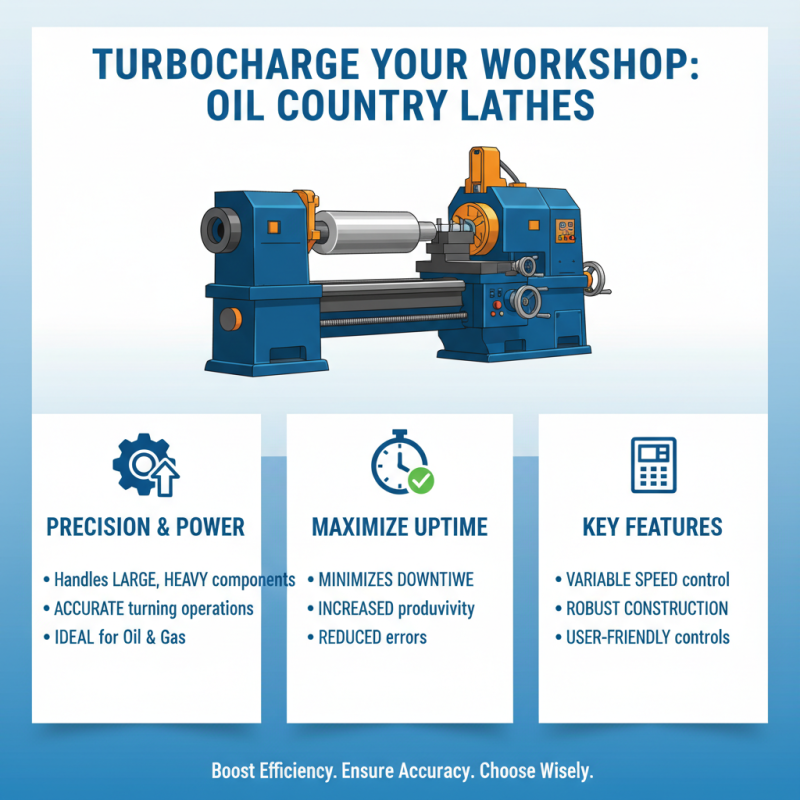

Top 10 Recommended Oil Country Lathes for Workshop Efficiency

When it comes to enhancing workshop efficiency, choosing the right oil country lathe is crucial. These machines are designed to handle large, heavy components typically found in the oil and gas industry, making them ideal for precision machining tasks. A high-quality oil country lathe not only ensures accuracy in turning operations but also minimizes downtime, allowing for more productivity. Features such as variable speed control, robust construction, and user-friendly controls can significantly enhance the machining process.

Selecting the top recommended oil country lathes involves considering factors such as spindle speed, torque capacity, and bed length. Lathes with higher torque are particularly valuable when working with tough materials, as they provide the necessary force to maintain cutting efficiency. Additionally, advanced digital control systems can improve the setup process, reducing setup time and boosting overall workflow. Investing in a reliable oil country lathe will ultimately transform your workshop's capabilities, enabling you to tackle projects with greater precision and efficiency.

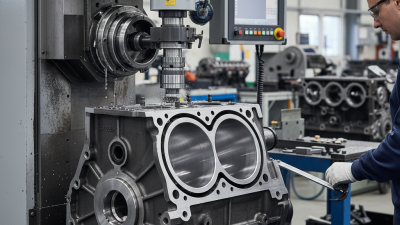

Comparison of Specifications and Performance in Leading Models

When selecting an oil country lathe for precision machining, it is essential to compare specifications and performance across various leading models. Factors such as bed length, spindle speed, and motor power play a crucial role in determining the efficiency and capability of each lathe. A lathe with a longer bed length provides more stability for larger workpieces, while higher spindle speeds allow for faster production rates without sacrificing quality. Additionally, an appropriate motor power is necessary to handle different materials, ensuring smooth operation even during heavy cutting tasks.

Performance metrics such as cutting precision, repeatability, and ease of use are equally important. Many modern oil country lathes feature advanced digital readout systems that enhance precision by providing real-time measurements. User-friendly controls can significantly improve workflow, allowing operators to quickly adapt to various machining tasks. Furthermore, considerations like maintenance accessibility and durability can influence a lathe's long-term reliability and performance, making it imperative to assess these specifications to find the most suitable model for your workshop needs.

Top 10 Oil Country Lathes for Precision Machining in Your Workshop

| Model | Swing Over Bed | Maximum Length of Workpiece | Spindle Speed Range | Horsepower | Weight |

|---|---|---|---|---|---|

| Model A | 18 inches | 60 inches | 50-1500 RPM | 7.5 HP | 2000 lbs |

| Model B | 20 inches | 80 inches | 45-1200 RPM | 10 HP | 2500 lbs |

| Model C | 22 inches | 100 inches | 30-1000 RPM | 8 HP | 3000 lbs |

| Model D | 25 inches | 120 inches | 40-1400 RPM | 12 HP | 3500 lbs |

| Model E | 30 inches | 150 inches | 20-800 RPM | 15 HP | 4000 lbs |

| Model F | 28 inches | 110 inches | 25-1200 RPM | 9 HP | 3200 lbs |

| Model G | 24 inches | 90 inches | 35-1300 RPM | 11 HP | 2700 lbs |

| Model H | 21 inches | 100 inches | 60-2000 RPM | 13 HP | 3300 lbs |

| Model I | 19 inches | 70 inches | 40-1500 RPM | 7 HP | 2100 lbs |

| Model J | 26 inches | 130 inches | 30-1000 RPM | 14 HP | 3800 lbs |

Maintenance Tips for Maximizing Longevity of Oil Country Lathes

Maintaining oil country lathes is crucial for ensuring their longevity and optimal performance in precision machining. Regular cleaning is one of the fundamental maintenance tasks; contaminants such as metal shavings and lubricants can accumulate and lead to wear and tear. After each use, operators should thoroughly clean the lathe, focusing on the bed, carriage, and headstock. Additionally, ensuring that the lubricant levels are appropriate and that the correct type of oil is used can significantly enhance the lathe’s functionality and durability.

Another vital aspect of maintenance is the regular inspection of components such as bearings and gears. During routine checks, operators should look for signs of wear, unusual noises, or vibrations that could indicate potential issues. Proper alignment of components is also essential; misalignments can lead to inaccuracies in machining and accelerate the deterioration of the lathe. Keeping the machine in a stable environment, free from excessive moisture and temperature fluctuations, is equally important, as this can prevent rust and other forms of degradation. By following these maintenance tips, users can ensure their oil country lathes remain efficient and retain their precision capabilities over time.

Related Posts

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry

-

2025 Top Universal Milling Machine Features and Buying Guide

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine

-

How to Choose the Right Universal Milling Machine for Your Needs

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs