Top 10 Press Brake Models for Accurate Metal Bending in 2026?

In the evolving landscape of metalworking, precision is paramount. Press brakes play a crucial role in achieving accurate bends in metal fabrication. Industry expert John Smith, a leading engineer in the field, states, "The right press brake can make all the difference." As technology advances, selecting the best models becomes more critical.

In 2026, several press brake models are set to rise to the top. Each model offers unique features that enhance efficiency and accuracy. Key factors to consider include tonnage, bend angle, and user-friendly controls. However, not all machines are perfect. Some models may have limitations which require careful evaluation.

It's essential to reflect on the specific needs of your operations. A powerful press brake can sometimes lead to over-reliance on automation. Striking a balance between technology and skilled labor is vital for the best results. By examining the top models, we can better understand how to optimize production while mitigating potential pitfalls.

Top 10 Press Brake Models for Accurate Metal Bending in 2026

In 2026, accurate metal bending will rely heavily on advanced press brake technologies. Industry reports indicate that the demand for precision metal fabrication has increased by 15% annually. This trend drives innovation in press brake models. These machines are essential for achieving the highest quality bends.

One key feature to look for is the system's alignment accuracy. A misaligned bend can result in wasted material and hours of rework. Some new models offer automatic alignment features, improving efficiency significantly. Despite these advancements, some machines still struggle with maintaining consistency across multiple bends. This inconsistency can impact production schedules.

Another critical factor is the control technology used. Modern press brakes with intuitive interfaces improve user experience. Still, many operators find that not all machines deliver the promised ease of use. Reports show that about 30% of operators experience a learning curve with new models. Addressing these challenges is crucial for ensuring the effectiveness of modern press brakes in metal bending.

Overview of Press Brake Technology Trends in 2026

Press brake technology continues to evolve in 2026, driven by trends in automation and precision. Recent reports indicate that 40% of manufacturers are now integrating advanced robotics into their workflows. This integration not only enhances productivity but also improves the accuracy of metal bending. Automated systems can minimize human error, reducing scrap rates by nearly 15%. Such advancements are crucial in a market that demands both speed and precision.

Another trend is the rise of smart technology. Modern press brakes are increasingly equipped with IoT capabilities. This allows real-time monitoring and data collection. According to industry analysts, 50% of manufacturers plan to adopt these smart features this year. This technology provides insights into performance, enabling operators to make informed adjustments. However, the learning curve remains steep. Many operators struggle to adapt to these systems.

Sustainability is also a growing concern in this sector. Reports show that 30% of factories are exploring eco-friendly materials and energy-efficient machines. While these developments are promising, the upfront costs can deter investments. Transitioning to green technology often requires a reevaluation of current practices. Thus, while the future appears bright, there are challenges that need addressing to fully embrace these innovations.

Key Features to Consider for Precision Metal Bending

When looking for a press brake model, precision is crucial. One important feature to consider is the machine's tonnage capacity. A higher tonnage allows for bending thicker materials. However, exceeding capacity can cause damage and affect accuracy. Choosing the right tonnage ensures both efficiency and quality.

Another key aspect is the control system. Modern press brakes often use CNC technology. This allows for precise adjustments and programming. But, there's a learning curve involved. Operators must be trained to use these advanced features effectively. Otherwise, mistakes can lead to wasted materials and time.

Tooling options are also essential. Various tools can create different bend angles and shapes. Operators should select tooling that complements their projects. It’s not just about having the latest tools; matching them to specific tasks improves performance. Without this alignment, achieving desired results becomes a challenge. Effective planning and training can help mitigate these issues.

Top 10 Press Brake Models for Accurate Metal Bending in 2026

| Model | Bending Capacity (Tons) | Max Bending Length (mm) | Accuracy (mm) | Control Type | Key Features |

|---|---|---|---|---|---|

| Model A | 100 | 3000 | ±0.02 | CNC | Automatic back gauge |

| Model B | 150 | 2500 | ±0.03 | Hydraulic | User-friendly interface |

| Model C | 80 | 4000 | ±0.01 | CNC | High-speed operation |

| Model D | 120 | 3200 | ±0.02 | Hybrid | Energy-efficient design |

| Model E | 90 | 3600 | ±0.02 | CNC | Compact design |

| Model F | 110 | 3000 | ±0.03 | Hydraulic | Precision bending tool |

| Model G | 130 | 2500 | ±0.02 | CNC | Advanced safety features |

| Model H | 140 | 2800 | ±0.03 | Hybrid | Multi-function capabilities |

| Model I | 160 | 3000 | ±0.01 | CNC | Fast response time |

| Model J | 170 | 3200 | ±0.02 | CNC | Robust construction |

Comparative Analysis of the Highest Rated Press Brake Models

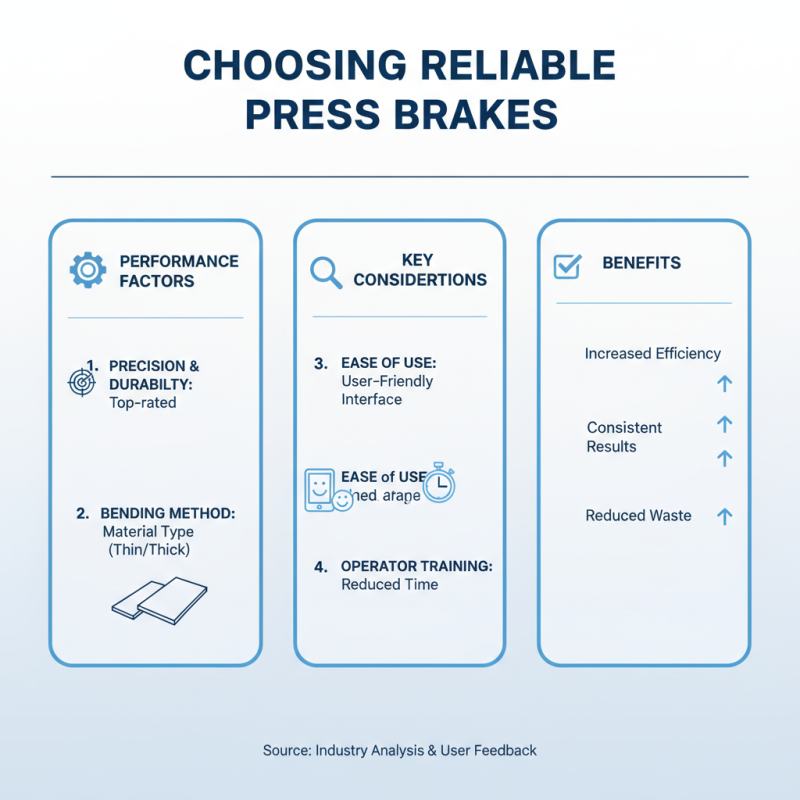

When looking for reliable press brakes, it’s vital to consider various performance factors. The highest-rated models tend to excel in precision and durability. Different models may use distinct methods for metal bending, which can impact the end result. One model might be great for thin sheets, while another excels with thicker materials. User feedback often highlights the importance of ease of use. A user-friendly interface can significantly reduce training time for operators.

However, not all features work for every application. Some models that perform excellently in one setting may fall short in another. Moreover, maintenance requirements can vary widely. Equipment breakdowns can lead to costly downtime—something many shops cannot afford. Operators should not overlook the learning curve associated with advanced features. A steep curve can hinder productivity, especially for teams accustomed to simpler machines.

Materials and tooling also play a critical role in metal bending accuracy. An ideal press brake should handle diverse materials effectively. Some models struggle with specific alloys, which may lead to unsatisfactory bends. It’s essential to weigh personal preferences against the capabilities of each machine. A well-informed decision will lead to improved outcomes and enhanced operational efficiency. Different aspects might prompt re-evaluation of choices down the line.

Industry Standards and Safety Regulations for Press Brakes

When using press brakes, adhering to industry standards is crucial. These machines must follow strict guidelines to ensure safe operation. The safety of workers is paramount. Proper guarding mechanisms should be in place to prevent accidents. Operators must be trained effectively. Lack of training can lead to mistakes.

Regular maintenance is another critical aspect. Machines need to be checked for wear and tear. Neglecting this can result in inaccurate bends. Poor maintenance might cause equipment failure during operation. Operators should perform daily inspections, and logs should be maintained.

Compliance with OSHA regulations is non-negotiable. These rules help in creating a safer work environment. It’s also essential to keep abreast of any updates to safety standards. Staying informed can lead to an overall enhanced workplace safety culture. It's worth considering how industry practices evolve. Adapting leads to improvements, but sometimes the changes can feel overwhelming. Balancing productivity and safety requires constant reflection.

Top 10 Press Brake Models for Accurate Metal Bending in 2026

Conclusion

The article "Top 10 Press Brake Models for Accurate Metal Bending in 2026" provides a comprehensive overview of the evolving landscape of press brake technology. It discusses the latest trends that are shaping the industry in 2026, including advancements in automation and precision engineering. Key features to consider for achieving accurate metal bending are highlighted, emphasizing the importance of selecting the right model to enhance efficiency and safety.

Furthermore, the article includes a comparative analysis of the highest-rated press brake models, helping manufacturers make informed decisions based on performance and reliability. Industry standards and safety regulations concerning press brakes are also reviewed to ensure compliance and optimal operation. Lastly, it looks ahead at future innovations in press brake designs, suggesting that ongoing improvements in this technology will lead to even greater efficiencies and capabilities in metal fabrication.

Related Posts

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry

-

Top 10 Tips for Using Band Saw BS712N Effectively?

-

Top 10 Oil Country Lathes for Precision Machining in Your Workshop

-

10 Essential Tips for Choosing a Universal Milling Machine

-

Why Choose a Sheet Metal Shearing Machine for Your Business Needs