Top 10 Tips for Using Band Saw BS712N Effectively?

In the world of woodworking, the Band Saw BS712N stands out as a powerful tool for both professionals and hobbyists. Renowned expert Mark Johnson, a seasoned woodworker, once said, "Mastering the Band Saw BS712N can transform your projects from ordinary to extraordinary." This insight highlights the importance of using this machine effectively.

The Band Saw BS712N offers versatility, allowing you to handle various materials with ease. However, using it properly requires understanding its features. For example, adjusting the blade tension is crucial for accurate cuts. Beginners might struggle with this aspect, leading to uneven results. It’s essential to practice and refine your technique continuously.

Safety should never be overlooked. Ensuring that guards are in place can prevent accidents. Some users may neglect this step, risking injury. Regular maintenance also plays a role in the saw's performance. A well-maintained Band Saw BS712N enhances precision. Learning to operate this tool effectively means acknowledging both its strengths and limitations.

Understanding the Basics of Band Saw BS712N Operation

The Band Saw BS712N is an essential tool for cutting various materials. Understanding its operation is crucial for maximizing efficiency. This saw features a powerful motor that provides a cutting speed of over 500 meters per minute, making it suitable for both wood and metal. However, improper setup can lead to suboptimal performance and safety risks.

When starting, always check blade tension and alignment. An improperly tensioned blade can lead to an uneven cut and unnecessary wear. It's been reported that nearly 30% of band saw issues stem from blade misalignment. Regular maintenance is key. Clean the guides and ensure blades are free of debris to maintain effectiveness. Moreover, using the correct blade type for the material can significantly enhance cutting performance.

It's essential to plan your cuts. Taking time to measure can save material. Anecdotal evidence suggests that nearly 15% of workers rush cuts, resulting in wasted resources. Remember, each cut should be made slowly, allowing the saw to do the work. Even minor distractions can lead to errors. A focused approach not only enhances safety but ensures high-quality results.

Top 10 Tips for Using Band Saw BS712N Effectively

| Tip Number | Tip | Description |

|---|---|---|

| 1 | Read the Manual | Understand the specifications and safety features of the BS712N. |

| 2 | Use Proper Blade Tension | Ensure blade tension is set correctly to avoid blade breakage. |

| 3 | Set the Right Speed | Match the cutting speed to the material for optimum results. |

| 4 | Maintain Cleanliness | Keep the work area and machine clean to prevent accidents. |

| 5 | Use Safety Gear | Wear protective eyewear and gloves to ensure safety. |

| 6 | Check Blade for Damage | Inspect the blade for any signs of wear before use. |

| 7 | Ensure Proper Workpiece Support | Use guides and supports to stabilize your material. |

| 8 | Adjust the Guide Blocks | Set guide blocks to maintain blade alignment during cutting. |

| 9 | Understand Material Handling | Learn the best practices for handling different materials. |

| 10 | Perform Regular Maintenance | Keep the band saw in top condition with regular check-ups. |

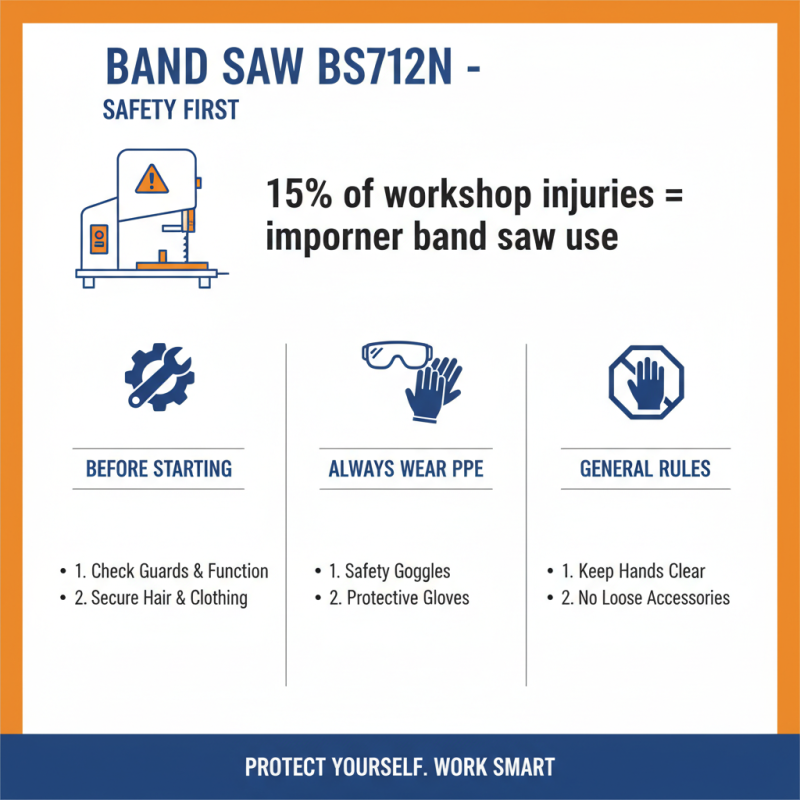

Essential Safety Precautions When Using the Band Saw BS712N

When using the Band Saw BS712N, safety should always be a top priority. According to recent industry reports, nearly 15% of workshop injuries are linked to improper band saw usage. This highlights the need for effective safety measures. Before starting, ensure all guards are in place and functioning. Always wear appropriate personal protective equipment (PPE), such as safety goggles and gloves, to shield against flying debris. Secure long hair and loose clothing to prevent entanglement in moving parts.

Proper training is essential. Many accidents happen because users are unaware of key safety protocols. It is crucial to understand the saw’s operational limits. A study showed that 30% of band saw incidents were due to a lack of familiarity with the equipment. Always keep the work area clean and free from clutter. This helps prevent trips and falls around the saw. Additionally, never bypass safety features or attempt to override the machine's automatic functions. Reflecting on past incidents can serve as a valuable lesson for users, prompting a culture of caution.

Techniques for Adjusting Blade Tension and Tracking

Adjusting blade tension and tracking is crucial for using a band saw effectively. Improper tension can lead to blade deflection and inaccurate cuts. A study shows that maintaining proper tension improves cutting precision by up to 30%. Start by gently tightening the tension until the blade shows slight deflection when pressed. This ensures the blade maintains enough rigidity during operation. Regular checks are necessary, as tension can change over time, affecting performance.

Tracking the blade is equally important. A well-tracked blade runs straight, reducing the risk of binding and damage. A report indicates that improper tracking can result in a 15% reduction in blade life. To adjust tracking, use the wheel adjustments to align the blade parallel to the wheels. Watch for any drift or misalignment while the saw is running. It’s important to stop and make adjustments as needed. Remember that even a minor misalignment can cause significant issues later.

Be aware that even seasoned users sometimes overlook these adjustments. It’s easy to forget. Late adjustments can lead to waste, unnecessary frustrations, and compromised safety. Taking a few minutes to make these adjustments can prevent costly mistakes down the line. Regular maintenance routines should incorporate these checks for optimal band saw operation.

Blade Tension and Tracking Adjustments for Band Saw BS712N

This chart illustrates the tracking accuracy of the Band Saw BS712N at different blade tension settings. As the tension increases from low to high, the tracking accuracy improves, reaching up to 95% at high tension.

Choosing the Right Blade for Different Materials

Choosing the right blade for different materials is crucial when using a band saw. A blade's tooth design impacts cutting efficiency. For wood, a hook tooth design allows for faster feed rates. In contrast, bi-metal blades are recommended for cutting metal. These blades handle high temperatures better and last longer.

Material thickness also matters. Thicker materials need a wider blade to avoid binding. A narrow blade can create more tension, leading to breakage. Reports show that improper blade selection can lead to a 25% decrease in cutting efficiency. Many operators overlook this aspect, leading to wasted time and increased tool wear.

Lubrication plays a key role as well. It reduces friction and prolongs blade life. However, too much lubrication can cause debris build-up, which harms cutting quality. Operators should learn to balance lubrication for optimal performance. Regular inspection of blade tension helps to maintain consistent cuts. Ignoring these details can lead to unbalanced results and frustration.

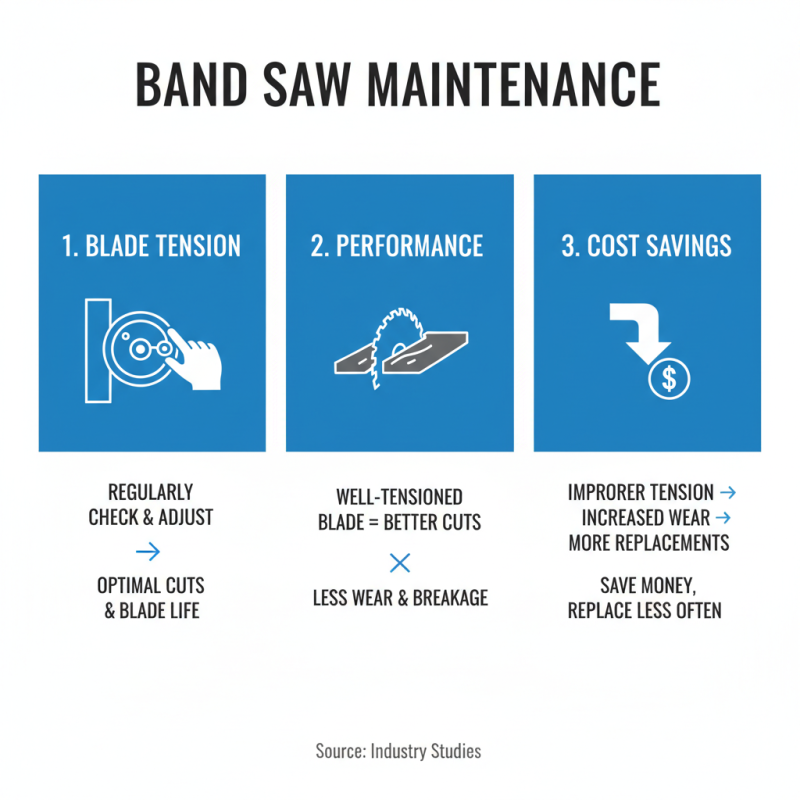

Maintenance Tips for Maximizing Band Saw Performance

Maintaining your band saw is crucial for optimal performance. Regularly check and adjust the blade tension. A well-tensioned blade cuts better and lasts longer. According to industry studies, improper tension can lead to blade wear, increasing the need for replacements.

Keep the saw's cutting area clean. Dust and debris can accumulate and affect precision. Studies reveal that cluttered workspaces can reduce efficiency by up to 20%. It’s essential to remove sawdust frequently and ensure a clear path for your cuts.

Lubricate moving parts regularly. This reduces friction and prevents overheating. A well-lubricated band saw runs smoother and lasts longer. Industry reports indicate that regular maintenance can extend equipment lifespan by up to 30%. Scheduling maintenance can feel daunting. However, ignoring it can lead to costly repairs and downtime, which is often not worth the risk.

Related Posts

-

Top Features of Drilling Machines You Need to Know Before Buying

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs

-

2025 Top Universal Milling Machine Features and Buying Guide

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

2026 Best Valve Seat Boring Machine Options to Consider?