Top 10 Tips for Using the Radial Drilling Machine Z3050x16 Effectively?

The Radial Drilling Machine Z3050x16 is a powerful tool in various industries. It offers versatility and efficiency for drilling operations. However, using this machine effectively requires knowledge and practice. Many operators struggle with its setup and operation. Common issues arise from improper adjustments or lack of familiarity with its features.

When using the Radial Drilling Machine Z3050x16, attention to detail is crucial. Small mistakes can lead to significant problems in production. Choosing the right speed and feed rate is essential. Operators often overlook this, leading to poor results. Understanding the machine's limits is vital to prevent damage.

Moreover, regular maintenance can’t be ignored. Neglecting upkeep diminishes performance over time. Operators must develop a routine for checking parts and ensuring everything runs smoothly. Despite its advantages, the Radial Drilling Machine Z3050x16 demands respect and caution. Recognizing potential challenges can lead to better results.

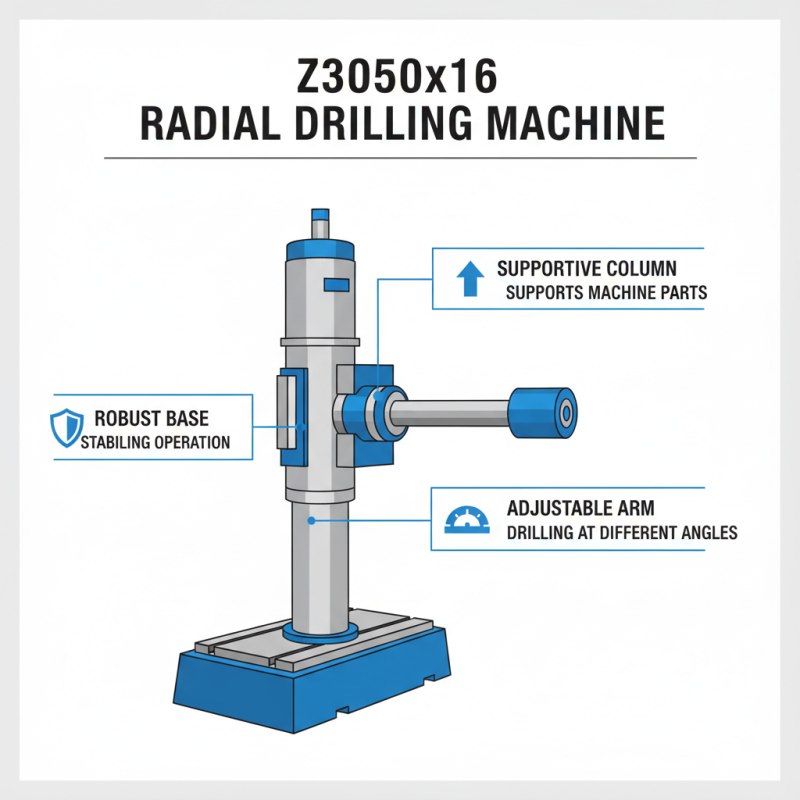

Understanding the Components and Functions of the Z3050x16 Radial Drilling Machine

The Z3050x16 radial drilling machine features several key components. Its base is robust and offers stability during operation. The column is a vertical structure that supports various parts of the machine. The arm is adjustable, allowing for drilling at different angles.

Understanding the headstock is crucial. It houses the drill chuck, which holds the drill bit. This part's adjustment can affect precision. Operators often overlook the importance of maintaining the headstock. Regular checks can prevent issues.

Another component is the feed mechanism. It controls how the drill bit penetrates the material. A faulty feed can lead to poor results. Users should familiarize themselves with this to improve efficiency. Learning how to share responsibility for maintenance can enhance performance. A collaborative approach often reveals overlooked areas needing improvement. Being aware of each piece's function can lead to better operation and outcomes.

Preparing the Work Area for Safe and Efficient Radial Drilling

Creating a safe and efficient workspace for the radial drilling machine is crucial. Start by clearing the area of any clutter.

Tools and materials should be organized. Ensure that the floor is clean and dry to prevent slips. Identify the hazards in your environment.

Look for overhead obstructions that may interfere with the machine's movement.

Lighting is another key element. Bright, focused light will help you see clearly.

Poor lighting may lead to mistakes. Make sure that all emergency exits are accessible. Keep the area well-ventilated if possible.

Air quality can affect your performance. It’s vital to have a comfortable working environment.

Having the right layout also matters. Position the drilling machine near power sources. This will avoid the chaos of tangled cords.

Establish a designated area for your materials. It helps in keeping track of everything. Remember, an organized workspace

can enhance your productivity significantly. Reflect on your workspace design periodically.

Adjustments may be needed over time for better efficiency.

Selecting the Right Drill Bit for Various Materials

Selecting the right drill bit is crucial when using the Radial Drilling Machine Z3050x16. Different materials require specific drill bits for optimal results. For instance, high-speed steel bits excel in softer materials, such as wood and plastic. Tungsten carbide bits are better suited for harder materials like metal and concrete. According to a recent industry report, using the correct drill bit can increase drilling efficiency by up to 25%.

When working with various materials, consider the bit's diameter and design. For thin materials, a smaller diameter bit prevents tearing. Wide bits are effective for creating larger holes. A common mistake is using the same bit for different tasks. This can lead to frustrating results and wasted time.

Tip: Always check the drill bit's sharpness before use. Dull bits increase resistance and lead to overheating.

Moreover, observe the feed rate. A slow feed improves accuracy but can be inefficient for thicker materials. Experimenting helps improve your skills. Ultimately, knowing when to adapt your approach is key. Keep a log of your experiences for future reference. You'll learn what works best for each scenario.

Top 10 Tips for Using the Radial Drilling Machine Z3050x16 Effectively - Selecting the Right Drill Bit for Various Materials

| Material Type | Recommended Drill Bit Type | Suggested Speed (RPM) | Feed Rate (mm/rev) |

|---|---|---|---|

| Mild Steel | High-Speed Steel (HSS) Twist Bit | 250-300 | 0.1-0.2 |

| Aluminum | Cobalt Twist Bit | 500-600 | 0.2-0.3 |

| Stainless Steel | Carbide-tipped Bit | 150-200 | 0.05-0.1 |

| Plastic | Standard Twist Bit | 300-400 | 0.2-0.25 |

| Wood | Spade Bit | 500-700 | 0.25-0.5 |

Mastering the Adjustments and Settings for Optimal Performance

Mastering the adjustments and settings of a radial drilling machine, like the Z3050x16, is crucial for achieving optimal performance. Understanding the correct settings can directly impact the quality of your work. For example, adjusting the spindle speed can improve drilling efficiency. Industry reports suggest that speed optimization can enhance tool life by up to 30%.

Tip: Regularly check your spindle speed. A lesser-known fact is that improper settings can lead to overheating. This not only damages the machine but also affects safety. Always consult the machine’s manual for recommended specifications.

When setting up, focus on the depth of the cut. Too deep can cause excessive strain. According to research, 25% of machine failures are linked to incorrect depth settings. A careful approach can minimize this risk.

Tip: Use depth stops wisely. They prevent accidental over-drilling. Remember, setting adjustments should be revisited frequently, especially after maintenance. It’s easy to overlook the basics, but they form the foundation of effective machining. Monitor your progress and adjust as necessary to ensure optimal outcomes.

Top 10 Tips for Using the Radial Drilling Machine Z3050x16 Effectively

Maintaining the Z3050x16 for Longevity and Reliability

Maintaining the Z3050x16 ensures its longevity and reliability. Regular cleaning is crucial. Dust and debris can accumulate quickly. Take time to wipe down surfaces after use. Consider using a soft brush for hard-to-reach areas. This simple step significantly reduces wear and tear.

Lubrication is another vital aspect. Check the machine's manual for recommended lubricants. Apply oil to moving parts regularly. This keeps everything running smoothly. However, avoid over-lubrication, which can attract dirt. Pay attention to the drill bit. Dull bits cause extra strain on the machine. Replace them as needed.

Always inspect the machine before use. Look for any signs of damage or wear. A small crack can lead to bigger problems. If something seems off, take a moment to investigate. It’s better to pause and fix an issue than to push through. Keeping track of maintenance history can help spot recurring issues. Regular checks create a more reliable machine.

Related Posts

-

Top Benefits of Using a Turret Milling Machine in Modern Manufacturing?

-

How to Choose the Right Cylinder Boring Machine for Your Needs?

-

How to Choose the Best CNC Lathe Machine for Your Workshop?

-

2026 Best Sheet Metal Shearing Machine Reviews and Buying Guide?

-

2026 How to Use Milling Machine X6325 Effectively?

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs