2025 Top Universal Milling Machine Features and Buying Guide

The landscape of machining technology is continually evolving, and among the pivotal tools that define this industry is the Universal Milling Machine. These machines are critical for a wide array of applications, showcasing versatility that meets the demands of various manufacturing sectors. According to a report by MarketsandMarkets, the global milling machine market is projected to reach USD 6.6 billion by 2025, underscoring the growing need for advanced machining solutions. The inherent adaptability of Universal Milling Machines contributes significantly to this market expansion, enabling manufacturers to enhance productivity and maintain competitiveness.

Industry expert John Smith, a leading figure in manufacturing technology, once remarked, "The Universal Milling Machine represents the cornerstone of modern machining, offering unparalleled flexibility and precision." This statement encapsulates the essence of why these machines are favored by both small workshops and large-scale manufacturing facilities alike. As we approach 2025, understanding the top features of Universal Milling Machines becomes crucial for businesses looking to invest wisely. The following guide delves into essential characteristics to consider when purchasing such a versatile machine, ensuring that your production capabilities remain at the forefront of innovation.

Key Features of Universal Milling Machines for 2025

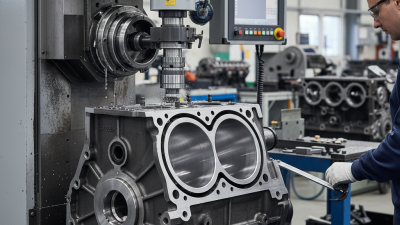

When considering a universal milling machine in 2025, several key features stand out that can significantly impact performance and usability. Firstly, precision and accuracy are paramount; modern universal milling machines are equipped with advanced digital displays and feedback systems that ensure exact measurements and improved machining results. Additionally, a robust build quality is essential, as it contributes to stability during operation and reduces vibrations, thereby enhancing the quality of the finished product.

Moreover, versatility is a critical attribute of these machines. The ability to handle various materials and work with different milling heads provides operators with the flexibility needed for diverse machining tasks. In 2025, the integration of smart technology will further enhance functionality, enabling features such as remote monitoring and automated adjustments. This not only streamlines the milling process but also allows for improved efficiency and reduced downtime, making it a valuable investment for any machining workshop. As such, prioritizing these essential features when purchasing a universal milling machine can lead to better operational outcomes.

Essential Considerations When Buying a Universal Milling Machine

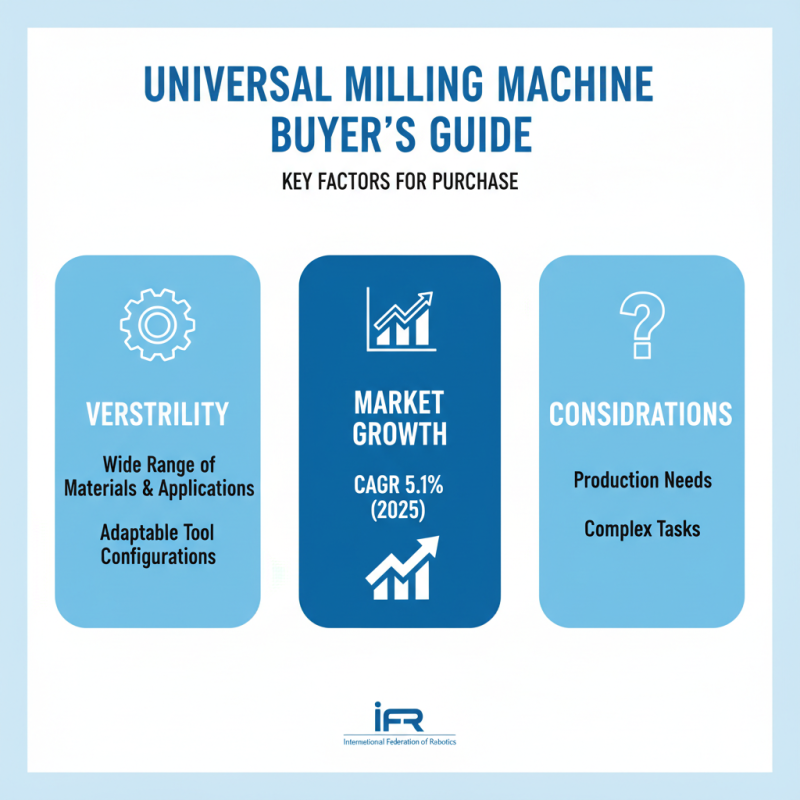

When considering the purchase of a universal milling machine, several essential factors come into play. The first key aspect is the machine's versatility. Universal milling machines are designed to handle a wide range of materials and applications, making them invaluable in both small workshops and large manufacturing facilities. According to a report by the International Federation of Robotics, the versatility of milling machines has led to a steady increase in demand, projected to grow at a CAGR of 5.1% through 2025. Prospective buyers should ensure that the machine can accommodate various tool configurations and handle complex machining tasks to meet their production needs effectively.

Another critical consideration is the machine's precision and performance capabilities. The accuracy of cuts and the ability to maintain tight tolerances are paramount for achieving high-quality results. Industry data indicates that machines equipped with advanced control systems and high-speed motors can significantly improve productivity and output quality. Features such as digital readouts, automated tool changers, and enhanced rigidity play a vital role in achieving precision. Buyers should evaluate the specifications and performance benchmarks, aiming for machines that meet their operational standards while ensuring cost-effective long-term investments.

Comparison of Popular Universal Milling Machine Brands in 2025

In 2025, the universal milling machine market has witnessed significant advancements in technology and innovation, leading to an increased variety of brands competing for consumer attention. A comparative analysis of popular universal milling machine brands reveals varying features that cater to different machining needs. Notably, factors such as precision, versatility, and ease of use have become crucial differentiators among leading manufacturers. According to a recent report by Grand View Research, the global milling machine market size is projected to reach USD 4.73 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.3% from 2020, indicating robust growth and heightened competition in the sector.

When exploring the features of different milling machine brands, it is essential to consider factors such as build quality, control systems, and automation capabilities. High-end models increasingly offer CNC integration, which provides enhanced precision and efficiency in machining operations. Furthermore, a survey conducted by Technavio highlights that approximately 60% of manufacturers prioritize machines with multifunctional capabilities to maximize productivity, making this a key feature in the current market landscape. As the demand for precision-engineered components continues to rise across industries such as aerospace, automotive, and electronics, the ability of these machines to perform diverse tasks will be a significant factor influencing purchasing decisions in 2025.

2025 Top Universal Milling Machine Features

This chart illustrates the top features of universal milling machines as rated by users in 2025. The features include Precision, Versatility, Ease of Use, Durability, and Cost-Effectiveness, with ratings based on user feedback.

Maintenance Tips for Prolonging the Life of Milling Machines

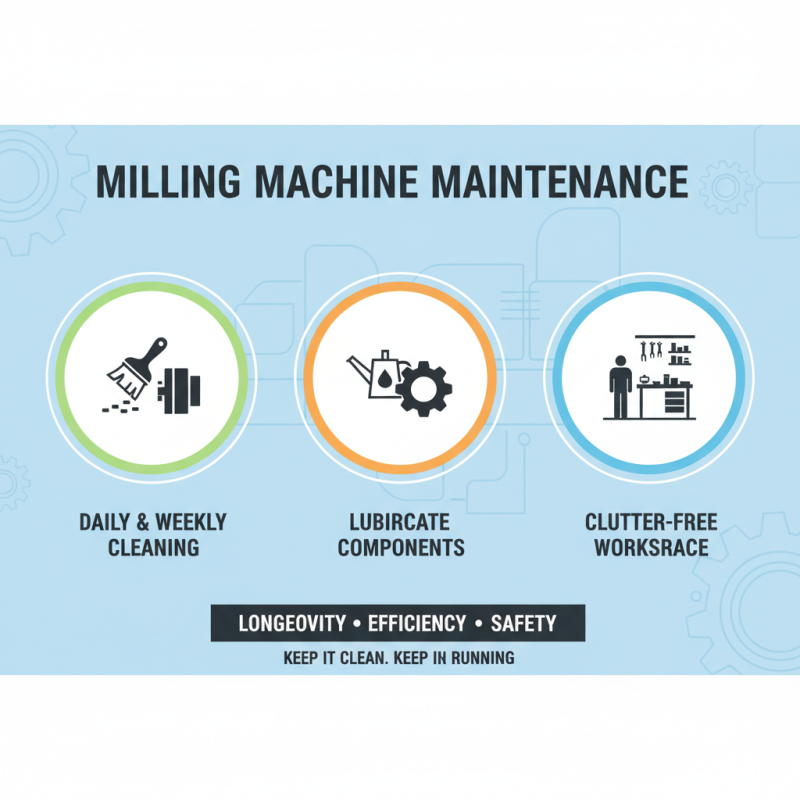

To ensure the longevity and optimal performance of milling machines, regular maintenance is essential. One of the most critical aspects of maintenance is keeping the machine clean. Dust, chips, and other debris can lead to wear and tear on moving parts, resulting in decreased efficiency and potential breakdowns. Operators should establish a routine cleaning schedule, incorporating both daily and weekly cleanouts to remove contaminants and lubricate components, as necessary. Additionally, maintaining a clutter-free workspace around the machine not only improves safety but also facilitates easier access for cleaning and inspections.

Another vital maintenance tip involves regular inspection of the machine's components. Operators should frequently check for signs of wear in gears, bearings, and cutting tools. This proactive approach allows for early identification of potential issues, which can be addressed before they develop into serious problems. Moreover, ensuring that all lubricants are fresh and at the proper levels greatly reduces friction and heat generation, which can otherwise contribute to premature component fatigue. Implementing a thorough check-up system, perhaps supported by a detailed logbook, can significantly enhance the machine's reliability and performance, protecting the investment for years to come.

Future Trends in Universal Milling Machine Technology and Design

The future of universal milling machine technology is poised for significant advancements that will enhance both efficiency and precision in manufacturing processes. One of the key trends shaping this evolution is the integration of smart technologies, such as IoT (Internet of Things) and AI (Artificial Intelligence). These technologies will enable real-time monitoring and data analytics, allowing operators to optimize machine performance, predict maintenance needs, and minimize downtime. As a result, manufacturers can expect increased productivity and reduced operational costs.

In addition to smart technologies, there is a growing emphasis on ergonomic design and user-friendly interfaces in milling machines. Future models are likely to feature advanced touchscreen controls and customizable settings that simplify operation for users of different skill levels. Furthermore, the trend towards modular designs is gaining momentum, enabling manufacturers to easily upgrade or modify their machines to suit specific production needs. This adaptability will not only enhance the lifespan of the equipment but also align with the evolving demands of various industries, paving the way for a more sustainable and versatile approach to manufacturing.

2025 Top Universal Milling Machine Features and Buying Guide

| Feature | Description | Future Trend |

|---|---|---|

| CNC Control | Integration of advanced CNC systems for precision machining. | Increased automation and smart technology integration. |

| Multi-Axis Capability | Ability to perform machining on multiple axes simultaneously. | Greater versatility and efficiency in complex part production. |

| Adaptive Machining | Machines adjust parameters based on real-time feedback. | Enhanced precision and reduction of material waste. |

| High-Speed Spindle | Spindles designed for high RPM to improve machining speeds. | Focus on speed and efficiency to meet increasing demand. |

| User-Friendly Interface | Simplified controls for easier machine operation and programming. | Implementation of touch screens and intuitive designs. |

| Energy Efficiency | Features designed to minimize energy consumption. | Growing focus on sustainability and energy savings in manufacturing. |

| Remote Monitoring | Capabilities for tracking machine performance remotely. | Integration of IoT technologies for machine health monitoring. |

Related Posts

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

2025 Guide: How to Choose the Right Cylinder Boring Machine for Your Needs

-

2025 Top Vertical Lathe Trends: What to Expect in the Industry

-

How to Choose the Right Turret Milling Machine X6325 for Your Needs

-

Essential Tips for Choosing the Right Cylinder Boring Honing Machine