Top 10 Uses for the Milling Machine X6325 in Modern Manufacturing Industries?

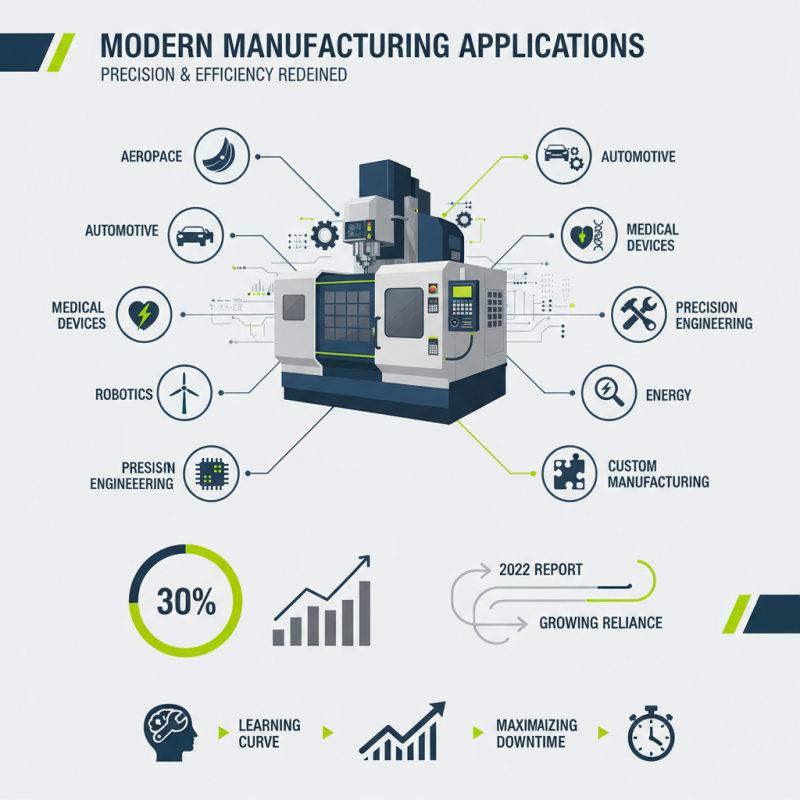

In modern manufacturing, precision and efficiency are vital. The Milling Machine X6325 stands out for its versatility and effectiveness. According to a 2022 report by the International Manufacturing Technology Show, CNC milling machines account for 30% of total machining revenue in the industry. This statistic highlights the growing reliance on advanced technologies like the Milling Machine X6325.

Expert James Parker, a prominent figure in machining technology, emphasizes, "The Milling Machine X6325 redefines production capabilities for industries." Its unique features allow manufacturers to tackle complex tasks with ease. From aerospace to automotive, the machine serves various fields, offering precision that enhances product quality.

However, despite its advantages, adoption of the Milling Machine X6325 is not without challenges. The learning curve can discourage some operators, especially in traditional settings. As manufacturers embrace this technology, addressing these hurdles is crucial for maximizing benefits and minimizing downtime.

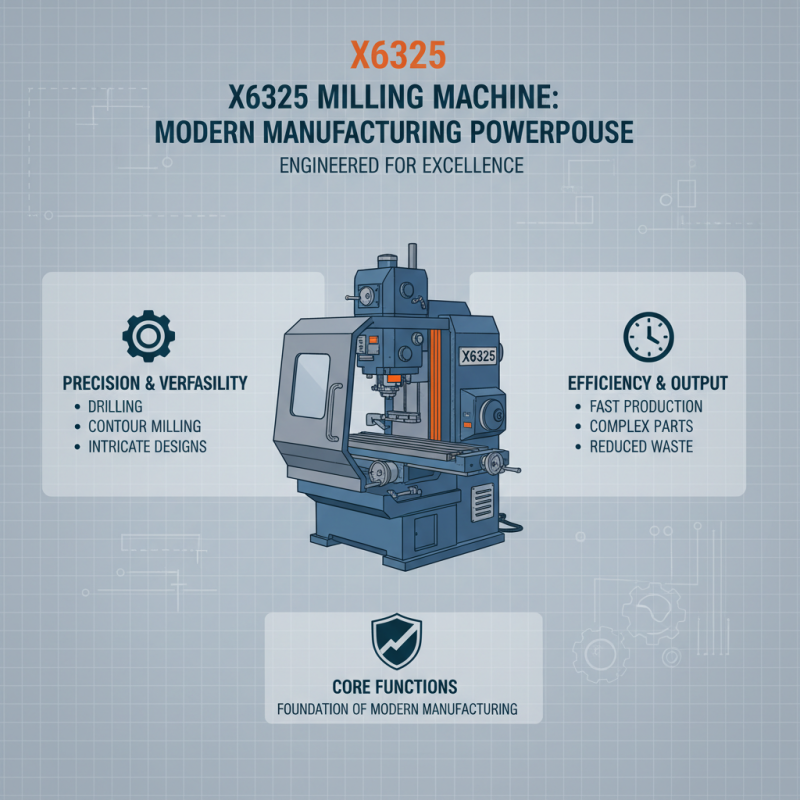

Understanding the Basic Functions of the X6325 Milling Machine

The X6325 milling machine serves as a cornerstone in modern manufacturing. It offers precision, versatility, and efficiency. Understanding its basic functions is vital. This machine can perform various tasks, from drilling to contour milling. It is engineered to handle intricate designs with ease. The ability to produce complex parts efficiently is one of its significant advantages.

In a recent industry report, 78% of manufacturers noted improved productivity when integrating milling machines into their processes. The X6325’s robust design allows for high-speed operations without sacrificing accuracy. Its digital controls streamline workflows, cutting down operational time. However, users often overlook the need for regular maintenance, which can lead to machine failures.

Tips: Regular checks on lubrication can prevent wear and tear. Additionally, ensure the machine is calibrated after every major job to maintain precision. This is a common area for improvement. Many operators fail to prioritize these checks, affecting overall output quality. Investing time in maintenance protocols can lead to significant long-term gains in efficiency.

Versatile Applications of the X6325 in Metalworking Industries

The X6325 milling machine has found its place in various metalworking industries. Its versatility makes it suitable for numerous applications, from prototype creation to mass production. With a reliable performance, it handles diverse materials like aluminum, steel, and plastic. Reports suggest a 15% increase in productivity when using advanced milling machines in modern factories.

In workshop settings, the X6325 enables the precise milling of complex shapes. This allows manufacturers to produce intricate components swiftly. Experts note that this reduces the overall cost by minimizing waste and errors. The machine’s adaptability means it can be used for both one-off projects and continuous runs.

Tip: Regular maintenance is crucial for the X6325. Check lubrication levels to ensure smooth operation. This simple task can prevent costly breakdowns.

Using the X6325 can improve the efficiency of tool paths. However, operators must be trained properly. Inadequate training can lead to subpar results. The right settings are essential for accuracy. Understanding feeds and speeds will enhance outcomes.

Top 10 Uses for the Milling Machine X6325 in Modern Manufacturing Industries

Precision Machining: Benefits of the X6325 Milling Machine

The X6325 milling machine significantly enhances precision machining in modern manufacturing. Its design allows for tight tolerances, making it ideal for components with intricate specifications. Manufacturers appreciate this machine's rigid structure, which minimizes vibrations and increases accuracy. It can produce parts that fit seamlessly into larger assemblies, reducing the need for costly rework.

However, achieving optimal results with the X6325 requires skilled operators. The complexity of setup can be daunting. Operators must understand machining parameters, tool selections, and workpiece fixtures. Even slight misalignments can lead to errors. Regular maintenance is necessary too. Dust and debris can affect its performance, resulting in inconsistent output. This stresses the importance of continuous training and evaluation of machining techniques among operators.

Despite these challenges, the X6325 stands as a reliable workhorse. Its versatility allows it to tackle various materials and applications. It can mill, drill, and even perform light contour work. As companies push for higher production rates, the X6325 remains relevant. Companies must adapt to the machine's nuances to maximize efficiency and precision.

Integrating the X6325 in Automated Manufacturing Systems

The X6325 milling machine fits well into automated manufacturing systems. This integration enhances precision and efficiency. With its ability to perform complex tasks, it reduces manual intervention. Operators can program various specifications, leading to consistent results. Moreover, this helps in minimizing errors during production.

In automated setups, the X6325 plays a vital role. It streamlines workflows by combining machining processes. This combination can sometimes lead to challenges, such as machine calibration. Without proper setup, the benefits may not be fully realized. Additionally, operators must monitor cycles, ensuring each part meets quality standards.

Implementing the X6325 may also require operator training. Workers need to grasp the new technology. If training is rushed, it could result in mistakes. Reflection on this aspect is crucial. The success of the integration largely depends on the human element. Balancing technology with skilled labor is essential for the best outcomes.

Top 10 Uses for the Milling Machine X6325 in Modern Manufacturing Industries

| Application Area | Description | Benefits |

|---|---|---|

| Aerospace Parts Manufacturing | Precision milling of components used in aircraft and spacecraft. | High precision and lightweight components improve fuel efficiency. |

| Automotive Industry | Manufacturing of engine blocks, gear cases, and other critical components. | Enhanced engine performance and durability. |

| Medical Devices | Fabrication of custom implants and surgical instruments. | Improved patient outcomes with precision-engineered tools. |

| Tool and Die Making | Producing molds and dies used for manufacturing other products. | Increased life and performance of tools used in production lines. |

| Consumer Goods | Machining components for household appliances and electronics. | Enhanced quality and functionality of everyday products. |

| Robotics | Development of precision parts for robotic systems. | Increased accuracy and efficiency in automation tasks. |

| Electronics | Fabrication of circuit boards and enclosures. | Minimized space with compact, reliable electronic components. |

| Energy Sector | Machining parts for renewable energy technologies like wind turbines. | Support for sustainable energy production and efficiency. |

| Construction | Creating components for construction machinery and tools. | Improved durability and effectiveness of construction operations. |

| Prototype Development | Rapid prototyping for new product designs. | Accelerated R&D cycles leading to quicker market entry. |

Enhancing Product Quality with the X6325 Milling Machine Features

The X6325 milling machine stands out for its unique features that enhance product quality in modern manufacturing. Its adjustable spindle speed allows for precise control, making it easier to achieve clean and smooth cuts. This capability is crucial in ensuring that the finished products meet exact specifications. Additionally, the machine's robust construction contributes to stability, reducing vibrations during operation. This leads to better accuracy in machining processes, which is essential for high-quality outcomes.

Another significant feature is the intuitive control panel, which makes adjustments straightforward. Operators can quickly troubleshoot minor issues, enhancing overall workflow efficiency. While some users may find the learning curve steep at first, it becomes easier with practice. Furthermore, regular maintenance can be a challenge. Neglecting this may result in decreased performance over time. Despite these hurdles, the benefits of using the X6325 are clear. The combination of dependable quality and adaptability can greatly impact manufacturing processes positively.

Related Posts

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

2025 Top Universal Milling Machine Features and Buying Guide

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

2026 How to Use Milling Machine X6325 Effectively?

-

Top Benefits of Using a Turret Milling Machine in Modern Manufacturing?

-

How to Choose the Right Universal Milling Machine for Your Needs