How to Use a Press Brake for Metal Bending and Fabrication?

Using a Press Brake is essential in the metal bending and fabrication industry. According to John Smith, a leading expert in metal forming, "A Press Brake is not just a tool; it's an art in precision." This statement resonates deeply with those who understand the intricacies of metalwork.

The Press Brake allows for various bending techniques. Each project presents its own unique challenges. Mistakes can happen; every fabricator has encountered a misalignment or a slip in measurement. These moments are crucial for learning and improving skills. Mastering the Press Brake can take time and practice.

In a world that demands accuracy, the importance of clear technique cannot be overstressed. A Press Brake is not merely about force; it’s about finesse. The potential for creating functional and aesthetic metal designs is immense. It requires patience and a desire to refine one’s craft. Embracing errors leads to growth, making the journey of using a Press Brake both rewarding and enlightening.

Understanding the Basics of Press Brake Operation

Understanding the basics of press brake operation is crucial for effective metal bending and fabrication. A press brake is a machine that bends metal sheets into desired shapes. The operator needs to set the correct die and punch for the specific bending task. Selecting the right materials is also fundamental. Not all metals respond the same way to bending. For example, aluminum behaves differently than steel.

It's essential to know the limits of the material. Over-bending can lead to cracks or weakened sections. Operators often make mistakes due to miscalculations or not accounting for material thickness. Checking the machine’s settings before starting is vital. Regular maintenance can help reduce errors but may not cover all issues.

Precision is key in press brake operation. A small error can result in significant discrepancies in the final product. Always measure twice before making cuts or bends. Operators must remain vigilant for any signs of wear on the machine. Learning from past mistakes is part of the journey. With practice, operators can improve their skills and achieve better results.

How to Use a Press Brake for Metal Bending and Fabrication

| Aspect | Details |

|---|---|

| Machine Type | Hydraulic Press Brake |

| Material Types | Aluminum, Steel, Stainless Steel |

| Bending Capacity | Up to 200 tons |

| Bending Length | Up to 3 meters |

| Angle Accuracy | ± 1 degree |

| Control Type | CNC Control |

| Common Bending Techniques | V-bending, U-bending, Z-bending |

| Safety Features | Emergency Stop, Light Curtains, Safety Guards |

| Typical Applications | Sheet metal fabrication, Structural components, Custom metal parts |

Types of Press Brakes and Their Applications in Metal Fabrication

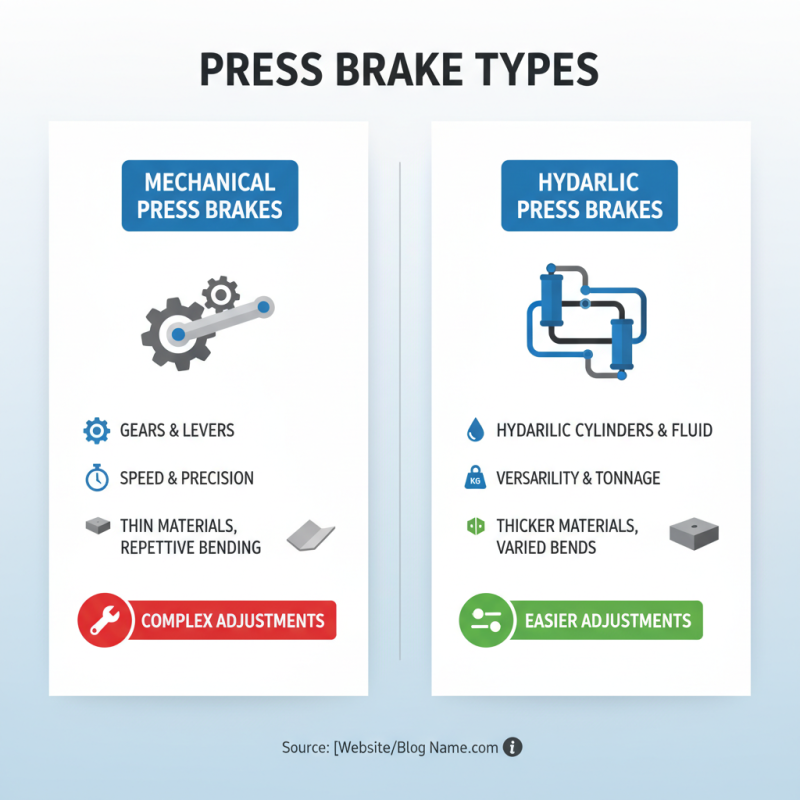

When considering types of press brakes, two main categories come to mind: mechanical and hydraulic. Mechanical press brakes use a system of gears and levers to operate. They are known for their speed and precision. Operators might find them ideal for thin materials and repetitive bending tasks. However, adjustments can be complex and may require skill.

Hydraulic press brakes, on the other hand, utilize hydraulic fluid for bending. This type is versatile and can handle thicker materials. They often provide greater force, making them suitable for heavy fabrication tasks. Nonetheless, their maintenance can be demanding, and leaks may occur over time. Each type has unique advantages and challenges.

Moreover, there are specialized press brakes, like CNC models, that provide automation. These machines enhance accuracy and efficiency in production. However, the initial investment can be high. Operators must evaluate their specific needs when choosing a suitable press brake. It's not just about the machine; it's also about the skill of the operator. Understanding these dynamics leads to better outcomes in metal fabrication.

Essential Safety Precautions When Using a Press Brake

When operating a press brake, safety is paramount. Always wear appropriate protective gear. This includes safety glasses, gloves, and steel-toed boots. Ensure the work area is clean and free of obstacles. Keeping your surroundings orderly minimizes accidents.

Before starting the machine, conduct a thorough inspection. Check for any wear or damage to tools and guards. If something seems off, address it before use. Accidents often happen because of overlooked details. Training is essential. Operators should understand how to maneuver the machine properly. Mistakes can lead to serious injuries.

During operation, maintain a safe distance from moving parts. Using clamps or fixtures can help secure materials. Never reach into the machine while it is in motion. If an emergency stops are needed, know where they are located. Reflecting on past experiences can help avoid repeat errors. Every process has room for improvement, including safety practices.

Step-by-Step Guide to Metal Bending with a Press Brake

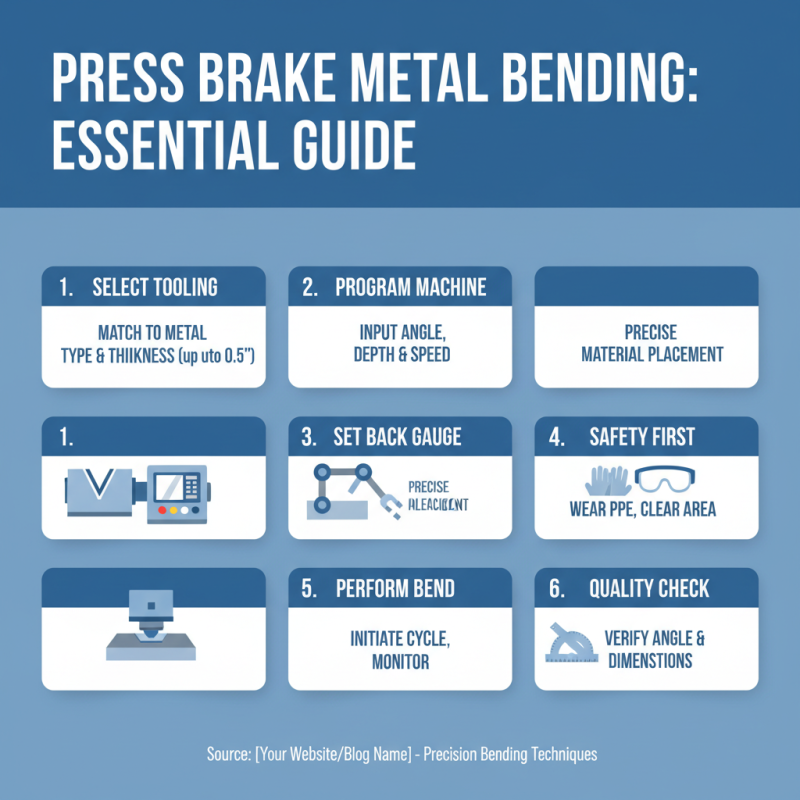

Using a press brake for metal bending requires understanding the process and equipment. This step-by-step guide covers essential techniques. Start by selecting the right tooling for your specific metal gauge and thickness. For instance, a standard press brake can bend materials up to 0.5 inches thick, but this varies widely depending on the machine capabilities.

Next, set your machine. Proper setup is vital for accuracy. Adjust the back gauge to ensure consistent bends. According to market reports, nearly 70% of bending defects arise from improper setups. Operators should frequently measure and recalibrate. Also, be mindful of the die design, as this impacts the bend radius significantly. The ideal bend radius should be 1.5 times the material thickness for optimal results.

As you proceed with bending, observe the metal closely. Look for signs of cracks or excessive springback. Interestingly, about 15% of parts fail quality checks due to these issues. Metal's behavior can be unpredictable. Understanding how different alloys respond to bending is crucial. Some may require pre-heating or post-heating to achieve desired outcomes. Bending is an art as much as a science, and each operation teaches valuable lessons.

Common Mistakes to Avoid While Operating a Press Brake

Operating a press brake is a skill that requires practice and attention. Many beginners overlook essential safety protocols. Always wear appropriate protective gear. Skipping this step could lead to injuries. Moreover, sitting or leaning on the machine while it operates is dangerous. Keep your workspace organized to avoid accidents.

One common mistake is miscalculating the bend angle. This can lead to wasted materials and time. Double-check measurements before starting any project. It's easy to become distracted and make errors. Take a moment to ensure everything is aligned properly. Also, be cautious with the tooling setup. Incorrect tools may lead to poor results or damage to the machine.

Another issue is rushing through the bending process. Press brakes require a steady hand and patience. Hurrying can lead to uneven bends or even malfunctions. Regular maintenance is essential too. Neglecting the machine can cause breaks and operational difficulties down the line. Operators should take time to reflect on their processes and always look for ways to improve efficiency and safety.

Press Brake Usage Statistics: Common Mistakes to Avoid

Related Posts

-

Top 10 Press Brake Models for Accurate Metal Bending in 2026?

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs

-

Top 10 Tips for Using Band Saw BS712N Effectively?

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

Ultimate Guide to Surface Grinding Machines Benefits Tips and Applications

-

Top Garage Equipment for Every Car Enthusiast What You Need to Know