2026 How to Use Milling Machine X6325 Effectively?

The effective use of the Milling Machine X6325 can significantly enhance production efficiency. According to a recent industry report, 70% of manufacturers experience productivity increases when using advanced milling machines. The X6325 stands out due to its precision and versatility. With its robust design and powerful motor, it can handle various materials, from metal to plastics.

However, many operators face challenges in maximizing its potential. A study found that improper setup and maintenance can lead to up to 25% downtime. Users must understand its features thoroughly to avoid these pitfalls. The X6325 requires regular calibration and operator training to ensure optimal performance. Awareness of these factors is crucial in a competitive landscape.

Industry data also reveals that 40% of machine failure could be avoided with proper training. This suggests that investing time in learning about the Milling Machine X6325 pays off. Users need to focus on how settings influence outcomes and reflect on their operational practices. Adopting best practices can transform milling operations and achieve better results in manufacturing.

Understanding the Components of the X6325 Milling Machine

The X6325 milling machine consists of several key components essential for effective operation. At its core, the machine features a robust bed that provides stability. This stability is crucial for precision. The table moves along two axes, allowing for accurate positioning of the workpiece. Understanding how to operate the table is vital. Operators must ensure it moves smoothly and is well-lubricated.

Another important component is the spindle. It houses the cutting tools, allowing for various milling processes. The spindle should be regularly checked for stability and alignment. An unstable spindle can lead to poor cut quality. Ensure tools are securely attached as well. Sometimes, operators overlook necessary adjustments, leading to frustration.

The control panel is equally significant. It provides access to various settings and operations. Familiarize yourself with the buttons and dials to avoid confusion. Improper settings can cause damage to the machine or the workpiece. Regular practice with the controls will enhance your efficiency. Always approach operation with a mindset for continuous improvement and learning.

2026 How to Use Milling Machine X6325 Effectively? - Understanding the Components of the X6325 Milling Machine

| Component | Function | Material | Importance |

|---|---|---|---|

| Spindle | Holds and rotates the cutting tool | Steel | Critical for precision cutting |

| Table | Supports the workpiece and enables movement | Cast Iron | Essential for stability during machining |

| Feed Mechanism | Controls the movement speed of the table | Steel and Aluminum | Important for the efficiency of the milling process |

| Coolant System | Reduces heat and clears chips from the cutting area | Variable (liquid solutions) | Crucial for tool longevity and workpiece quality |

| Control Panel | Interface for operating the machine | Plastic and Metal | Vital for user interaction and machine settings |

Setting Up the X6325 Milling Machine for Optimal Performance

Setting up the X6325 milling machine requires careful attention to detail. Start by placing the machine on a stable surface. Ensure it is level to avoid vibrations during operation. The work area should be clean and free of any obstructions. Proper lighting is essential for visibility. A well-organized workspace can boost productivity.

Next, adjust the machine parameters. Calibrate the spindle speed for your specific project. Too fast can lead to poor cuts, while too slow may cause tool wear. Use the appropriate cutting tools that match the material you are working with. Check the tool alignment closely to avoid unexpected results.

It's also important to routinely check for wear and tear. Monitor the machine's performance continually. If something feels off, take the time to investigate. Remember, small issues can escalate into larger problems. Reflecting on your setup process can reveal areas for improvement. Each project can provide valuable insights for the next.

2026 Milling Machine X6325 Performance Metrics

This chart displays the performance metrics for the X6325 milling machine, including speed, feed rate, depth of cut, and tool wear. These metrics are essential for optimizing machine operation and achieving the best results in milling tasks.

Essential Safety Precautions When Using the X6325 Milling Machine

When operating the X6325 milling machine, safety should be a primary concern. Wearing proper personal protective equipment (PPE) is non-negotiable. This includes safety glasses, ear protection, and steel-toed boots. A staggering 33% of machine-related injuries are due to lack of proper safety gear. Even a moment's negligence can lead to serious injury.

Understanding the machine's operational limits is crucial. The X6325 is designed for specific materials and thicknesses. Overloading the machine can lead to malfunction or accidents. Regular inspections of the machine can prevent mishaps. Reports suggest that 60% of workplace injuries arise from inadequate maintenance. Using the X6325 without checking its condition can be a grave mistake.

Moreover, it’s vital to maintain a clean workspace. Clutter can lead to slips and falls. A clean environment also ensures that all controls are easily accessible. Industry statistics reveal that workplaces with organized setups experience 40% fewer accidents. Operators should also be trained to recognize warning signs of malfunction. Ignoring these signals can turn routine tasks into hazardous situations. Ensure you’re always aware of your surroundings when operating this machine.

Techniques for Effective Milling Operations with the X6325

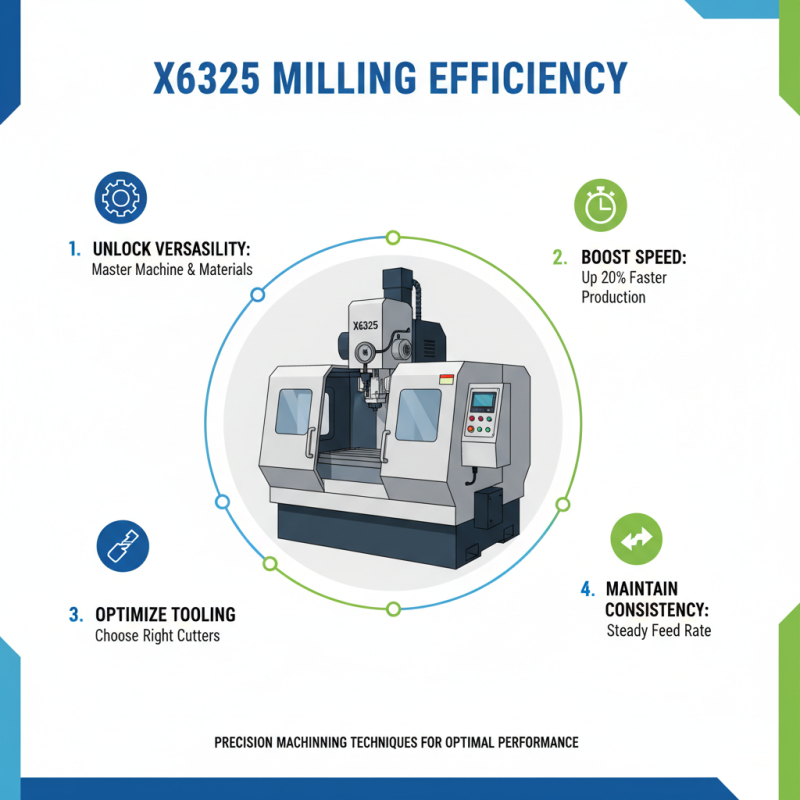

Milling operations with the X6325 can be efficient when approached with the right techniques. Operators often overlook the machine's versatility. Using it effectively requires an understanding of both the equipment and the materials. According to recent industry reports, precision machining can improve production speeds by up to 20%. Choosing the right cutting tools and maintaining a consistent feed rate are crucial.

Tips: Always calibrate the machine daily. This ensures accuracy and reduces wear on components. Regular maintenance can extend the machine's life dramatically.

Another area of focus is the workpiece setup. A secure setup prevents vibration, which can lead to poor surface finishes. Operators should use vises and clamps for stability. Industry analysis suggests that improperly secured pieces account for about 15% of machining errors. When milling aluminum versus steel, adjust the speed settings. Aluminum often requires higher RPMs, while steel benefits from lower speeds and more torque.

Tips: Document each setup and adjustments you make. This record can help pinpoint areas for improvement. Analyzing past mistakes can guide future setups to achieve better results. Regularly reviewing performance leads to ongoing improvements in milling operations.

Maintenance Tips to Ensure Longevity of the X6325 Milling Machine

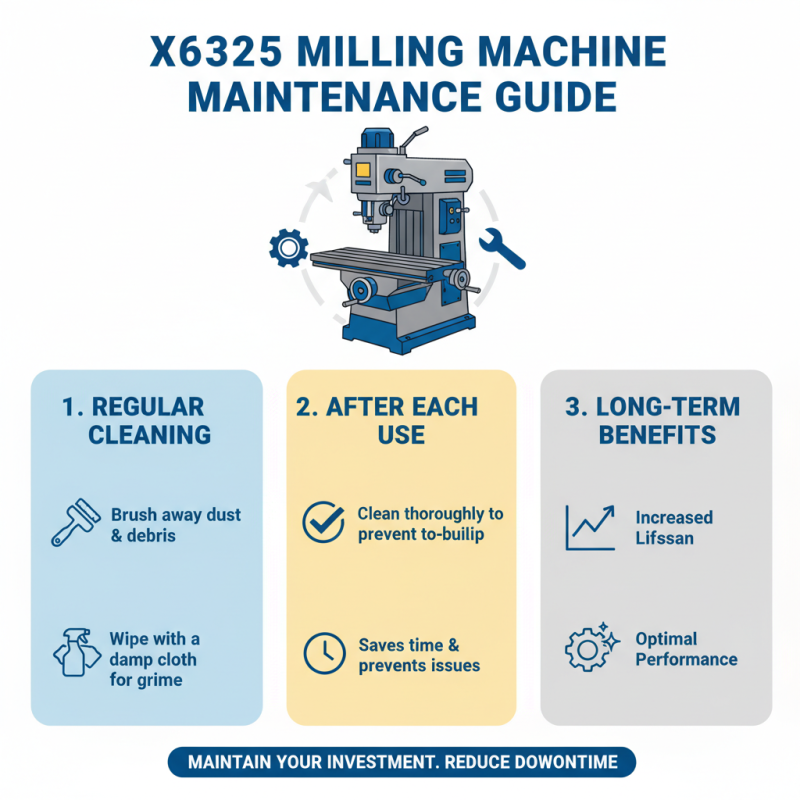

Maintaining a milling machine like the X6325 is crucial for its lifespan. Regular cleaning is essential. Dust and debris can accumulate quickly, affecting performance. Use a soft brush to clear off any particles. A damp cloth can help remove stubborn grime. Ensure that you clean the machine after each use. Neglecting this simple step can lead to more significant issues over time.

Lubrication is another vital aspect to consider. Check the machine's manual to identify the appropriate lubricants. Apply oil to moving parts regularly. However, avoid over-lubricating, as this can attract more dust. The right amount makes a difference in smooth operation. Also, remember to inspect belts and gears for wear and tear. Replace any worn components promptly to prevent further damage.

Lastly, it's wise to keep a maintenance log. Documenting routine checks and repairs can help track the machine's condition. This practice may reveal patterns of wear that require attention. Don't overlook small issues; they can escalate quickly. Regular maintenance not only extends the life of the X6325 but also enhances its performance. Evaluating your practices periodically is necessary for continuous improvement.

Related Posts

-

Top 10 Benefits of Using a Turret Milling Machine X6325 for Your Projects

-

2025 Top Universal Milling Machine Features and Buying Guide

-

10 Essential Tips for Choosing the Right Milling Machine for Your Needs

-

How to Choose the Right Universal Milling Machine for Your Needs

-

Why Choose a Sheet Metal Shearing Machine for Your Business Needs

-

Top Features of Drilling Machines You Need to Know Before Buying