Why Choose a Valve Seat Boring Machine for Engine Maintenance?

In the world of engine maintenance, precision is crucial. Experts highlight the importance of the right tools for effective repairs. John Smith, a seasoned technician in the automotive field, states, “A Valve Seat Boring Machine is key to achieving optimal engine performance.” This emphasizes how vital this equipment is for ensuring engine longevity.

Investing in a Valve Seat Boring Machine allows mechanics to maintain proper valve seating. The machine accurately bores valve seats to fit precisely. When using this machine, mechanics can enhance engine efficiency. This results in better fuel consumption and reduced emissions. However, improper setup can lead to poor results, showing that skill is essential.

Using a Valve Seat Boring Machine reflects a commitment to quality. It’s not just about the machinery; it’s about the technician’s expertise. Some may overlook the need for training, which can lead to mistakes. Failing to master this tool might result in lost time and ineffective repairs. Hence, both the machine and the operator play crucial roles in effective engine maintenance.

Benefits of Using a Valve Seat Boring Machine

A valve seat boring machine is essential for engine maintenance. It provides precision and accuracy when working on valve seats. This machine ensures a proper fit, which is vital for optimal engine performance. Without this accuracy, engines may face power loss or increased emissions over time.

Using this machine minimizes errors commonly made by hand tools. It allows for consistent depth and angle adjustments, which are crucial for effective sealing. Properly bored valve seats lead to better compression and efficiency. Poor machining can create significant problems, resulting in costly repairs. The machine also supports various engine types, enhancing its usability.

While valve seat boring machines are highly effective, they require skilled operators. Inexperienced use can lead to mistakes, impacting overall results. Attention to detail is crucial during the machining process. Small oversights can result in larger issues later. Regular maintenance of the machine itself is necessary to ensure optimal performance.

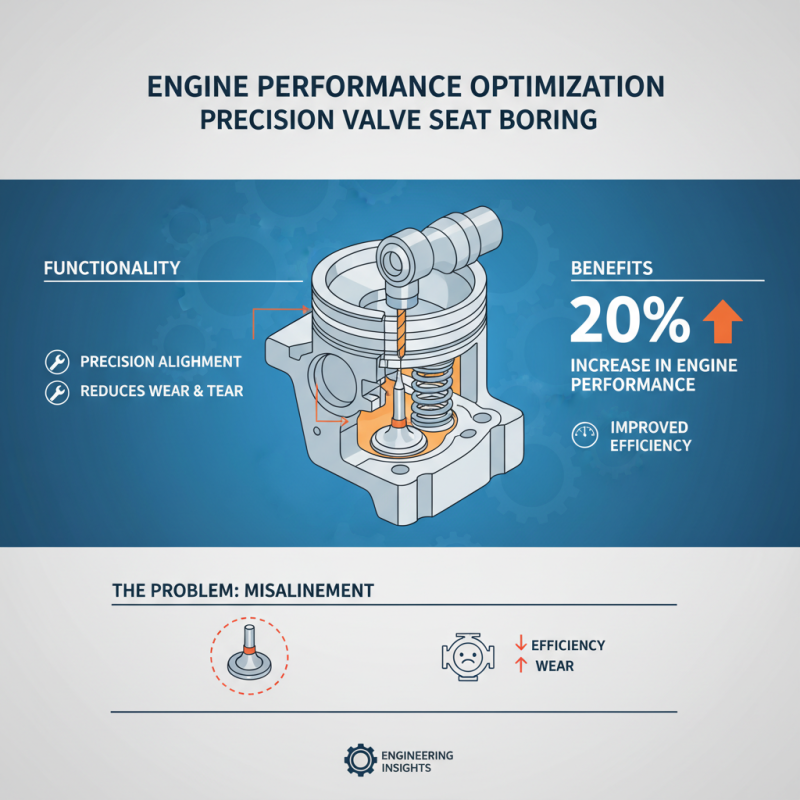

Understanding the Functionality of Valve Seat Boring Equipment

When it comes to engine maintenance, understanding the functionality of valve seat boring equipment is crucial. This machinery allows for precision work on valve seats, ensuring a perfect alignment with the valve itself. According to industry reports, using a valve seat boring machine can yield a 20% increase in engine performance. When the valve seat is improperly aligned, engine inefficiency increases. This leads to increased wear and tear.

Tips: Regularly inspect your valve seats to avoid misalignment. Small issues can become costly repairs later.

Valve seat boring machines are designed to remove material and refurbish valve seats. They create a uniform surface, critical for optimal sealing. Studies have shown that improper sealing can result in a 30% loss in compression, negatively affecting performance. Operators must grasp how to utilize the machinery effectively. Mistakes can lead to uneven surfaces, negating potential benefits.

Tips: Always calibrate your machine before use. Calibration errors can cause long-term damage.

Furthermore, some operators overlook the importance of tool maintenance. Dull tools can produce poor results and require more time and resources to correct. Regular maintenance can reduce this risk. A well-maintained tool facilitates better cuts, increased accuracy, and lower operational costs. Engine builders who invest in quality machines and training will see a clear return.

Comparing Valve Seat Boring Machines to Traditional Methods

When it comes to engine maintenance, choosing a valve seat boring machine offers distinct advantages. Traditional methods often lead to inconsistency. Manual work can produce variable results, impacting engine performance. This inconsistency might frustrate mechanics and lead to costly rework.

Valve seat boring machines provide precision. They remove material evenly from the valve seat. This ensures a perfect fit for the valve. A better seal improves engine efficiency. Details matter in engine performance. An uneven seat can cause leaks, leading to power loss or poor fuel economy.

However, not every mechanic embraces this technology. Some may resist change, sticking to familiar practices. There is a learning curve associated with new machines. Mistakes can happen during the transition, resulting in wasted resources. But the long-term benefits often outweigh initial challenges.

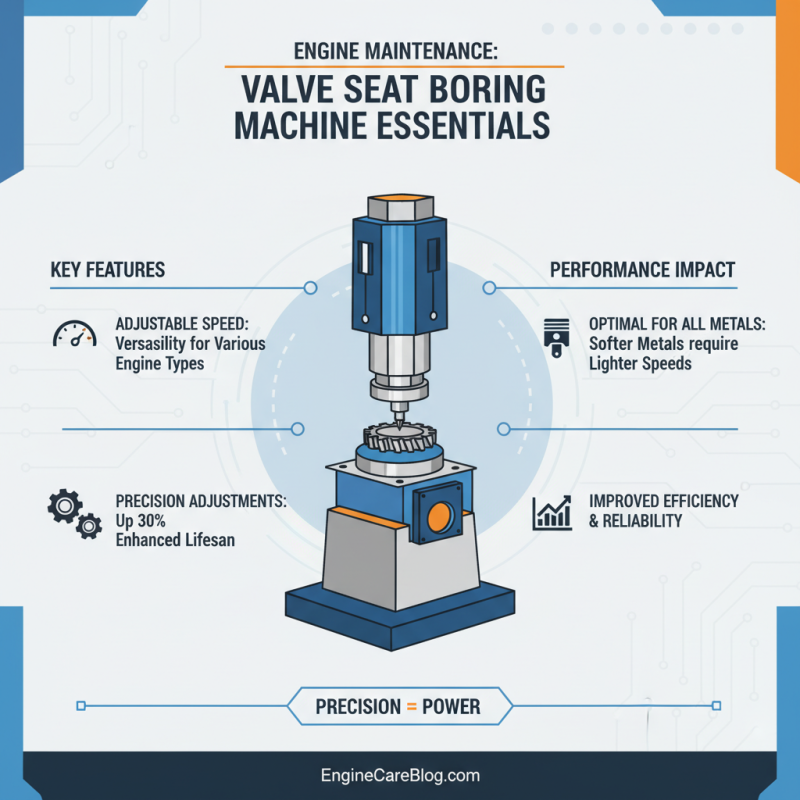

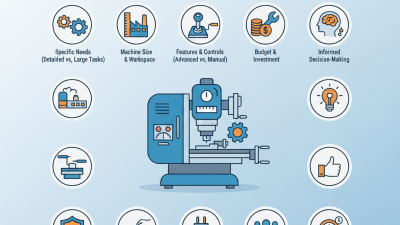

Key Features to Look for in a Valve Seat Boring Machine

When it comes to engine maintenance, a valve seat boring machine is essential. Its precision can make a big difference. Key features can significantly impact performance. A good machine should have adjustable speed. This flexibility allows for various engine types. Different engines require different approaches. For instance, lighter speeds help with softer metals. Research indicates that precise adjustments can enhance lifespan by up to 30%.

Another critical feature is the toolholder design. A stable toolholder ensures consistent performance. It minimizes vibrations. Reports show that machines with better tool stability can reduce wear and tear on parts by 15%. Additionally, user-friendly controls are vital. Operators often benefit from intuitive interfaces. This can decrease the learning curve by 20%, making training more effective.

Maintenance is also a factor. Machines that are easy to maintain often result in fewer downtime hours. Studies have shown that consistent upkeep correlates with a 25% increase in machine longevity. However, it's important to remember that some machines may still have flaws. Choose wisely, considering both features and reliability.

Best Practices for Maintaining Engine Components with Boring Machines

Using a valve seat boring machine can greatly enhance engine maintenance. This machinery allows precision adjustments for valve seats, which is crucial for optimal engine performance. When maintaining engine components, it’s essential to focus on the small details. Regular checks on valve angling and surface finish can prevent serious issues later.

Proper setup of the boring machine includes ensuring that all measurements are accurate. Misalignment or incorrect settings could lead to excessive wear. It's vital to frequently inspect the boring tool for any signs of dullness or damage. This will help maintain the quality of work. Remember, the condition of the machine directly influences the final output.

In addition to proper equipment handling, a clean workspace is critical. Dust and debris can accumulate on parts and affect engine performance. Developing a routine for cleaning and organizing tools can mitigate potential errors. Careful attention to these practices can enhance the longevity of both the machine and the engine parts being serviced. Think about the implications of neglecting these areas; small oversights can lead to larger problems down the road.

Why Choose a Valve Seat Boring Machine for Engine Maintenance?

| Aspect | Details |

|---|---|

| Precision | Ensures accurate valve seat dimensions for optimal engine performance. |

| Enhanced Performance | Improves sealing and combustion efficiency, leading to better power output. |

| Durability | Extends the life of engine components by maintaining optimal geometry. |

| Cost-Effectiveness | Reduces long-term repair costs by addressing issues proactively. |

| Ease of Use | User-friendly operation with minimal training required for technicians. |

| Versatility | Applicable to various engine types and sizes, enhancing workshop capabilities. |

| Technological Advancements | Incorporates modern technology for improved accuracy and efficiency. |

| Maintenance | Regular use leads to better overall engine maintenance and longevity. |

Related Posts

-

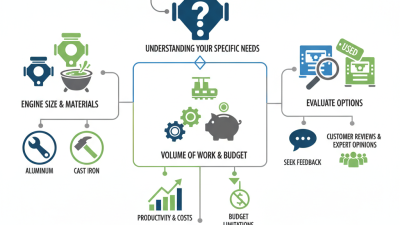

How to Choose the Right Cylinder Boring Machine for Your Needs?

-

How to Choose the Best Profile Bending Machine for Your Metalworking Needs

-

Top 10 Tips for Using an Oil Country Lathe Effectively?

-

2026 How to Use Milling Machine X6325 Effectively?

-

2025 Top Universal Milling Machine Features and Buying Guide

-

10 Essential Tips for Choosing a Universal Milling Machine